Ok. I have a 55 gal that I use to collect my RO water in. I got it from my brew buddy that owns the LHBS. They are great.If you read @ba-brewer, it's my mash tun being depressed because no grain in it. It is, in reality, my mash tun. Which is a repurposed 16g extract barrel, the kind you see at the LHBS. Works great, mainly because it was practically free, and also because it's wrapped in two thicknesses of thermowrap and has a tight lid. Now it has a better false bottom however I need to increase my strike temp, as it only got up to 146 today. No matter, got good gravity out of the wort and it will be BEER.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Kegged the first batch of my pipeline restart.

Definitely gonna do the "shake'n'bake" fast carb thing on one of the two kegs. Daddy needs neipa!

Cheers!

Definitely gonna do the "shake'n'bake" fast carb thing on one of the two kegs. Daddy needs neipa!

Cheers!

Just cleaned up a bunch of stuff that was drying from previous rack to keg day last weekend. And drank...what seems like a lot.

bracconiere

Jolly Alcoholic - In Remembrance 2023

got good gravity out of the wort and it will be BEER.

i don't why, but it tickles me pink to read you type beer in all caps! glad that flase bottom is working for you, i always had to put a copper scurnchy under it to get it to work!

- Joined

- Feb 19, 2017

- Messages

- 979

- Reaction score

- 1,238

Made v14 of Machine House Mild clone tonight. Hopefully zeroing in on something close. I know the OG, FG, yeast, the actual malts (but not the %). Challenge accepted to figure out on my system the right mash temp, utilization rates, ferment temp, spunded in the keg to get something appreciably close to a cask conditioned Mild with a hand pump. Triangulating in...

None of my attempts have been bad per say, but not as close to the ambrosial qualities of what Machine House does. A couple more tries and I'll have to pay another visit and see if I can get more details out of the braumeister. He's a really nice bloke from the UK. I would go more often but it's out of the way and I need to stay driving sober....

I also split a cyser with 2 gallons into a keg and dry hopped with 25 grams bramling cross, and the other 2 gallons with 25 grams of oak chips to soak for a while. This is with Sake #9 and nottingham yeast. I shant be doing the Sake #9 again. It embues a "pukey" taste for about 1 month before fading. My cysers are kinda like start pulling half pints when og hits 1020, and the pukey lag time isn't conducive to that.

Also have a different cyser with fresh juice from Costo and costco honey for a 1080 OG batch. Straight Nottingham yeast is slowly chewing thru this in my unheated garage and now down to about 1040.

Oh, and I cut up and freeze my leftover pumpernickel loafs to save for a kvass and/or a pumpernickel inspired dark beer of some sort. I typically make a 2.5# loaf each weekend, and the family gets thru 80-100% during the week.

None of my attempts have been bad per say, but not as close to the ambrosial qualities of what Machine House does. A couple more tries and I'll have to pay another visit and see if I can get more details out of the braumeister. He's a really nice bloke from the UK. I would go more often but it's out of the way and I need to stay driving sober....

I also split a cyser with 2 gallons into a keg and dry hopped with 25 grams bramling cross, and the other 2 gallons with 25 grams of oak chips to soak for a while. This is with Sake #9 and nottingham yeast. I shant be doing the Sake #9 again. It embues a "pukey" taste for about 1 month before fading. My cysers are kinda like start pulling half pints when og hits 1020, and the pukey lag time isn't conducive to that.

Also have a different cyser with fresh juice from Costo and costco honey for a 1080 OG batch. Straight Nottingham yeast is slowly chewing thru this in my unheated garage and now down to about 1040.

Oh, and I cut up and freeze my leftover pumpernickel loafs to save for a kvass and/or a pumpernickel inspired dark beer of some sort. I typically make a 2.5# loaf each weekend, and the family gets thru 80-100% during the week.

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

- Joined

- Feb 19, 2017

- Messages

- 979

- Reaction score

- 1,238

I baked a pumpernickel loaf tonight, and took advantage of the oven to make about 1/2 pint of invert #1, #2 & #3

Doing another neipa today, doughed in and cruising...

30 minutes in, close enuff!

Onwards!

The Spousal Unit decided to have a computer meltdown over a suddenly dysfunctional mouse. Fortunately I had just started mash out so had 20 minutes to deal with her issue. Which turned out to be an errantly switched device selector on the mouse - it wasn't controlling anything

So, mash out happened. Most of the way through the fly sparge now...

Go sparge go!

Epilogue: one of my smoothest brew days is done. I might be getting the hang of this brewing thing

Wort gassed and keg purge system hooked up and ready to go!

Time for the yeast to step up to the plate!

Cheers!

30 minutes in, close enuff!

Onwards!

The Spousal Unit decided to have a computer meltdown over a suddenly dysfunctional mouse. Fortunately I had just started mash out so had 20 minutes to deal with her issue. Which turned out to be an errantly switched device selector on the mouse - it wasn't controlling anything

So, mash out happened. Most of the way through the fly sparge now...

Go sparge go!

Epilogue: one of my smoothest brew days is done. I might be getting the hang of this brewing thing

Wort gassed and keg purge system hooked up and ready to go!

Time for the yeast to step up to the plate!

Cheers!

Last edited:

Nick&Worty

Well-Known Member

- Joined

- Sep 2, 2020

- Messages

- 282

- Reaction score

- 440

Woops.. this was supposed to be hard cider, not wine lol

My buddy that has a brewpub has three of the 55 gallon drums that we used to use for fermenters until he got his shiny fancy SS ones. He still uses them for sours. B*tch to clean but they made some damn good beers.Ok. I have a 55 gal that I use to collect my RO water in. I got it from my brew buddy that owns the LHBS. They are great.

Bottled my dunkelweizen that I fermented warm and with stressed yeast to get more banana character for the 24 days of Christmas homebrew club trade. I soaked .5lb of toasted cacao nibs in secondary for a chocolate covered banana type flavor. We got 24 members to all brew a different beer and each were assigned a day number. Stoked to get my box at the end of the month !!

Came home from work tonight to find the Citra/Sabro IPA I brewed on Sunday had dropped its krausen like the proverbial rock; pitched 2nd gen Notty on it that took off like crazy and apparently really liked what it had to eat. Dropped the dry hop (2oz of sabro and 1oz of Citra Lupomax) in it with an eye to kegging this weekend. And since I'll have a free fermenter.....planning a batch of the house American Strong that can sit in the ferment fridge for a few weeks while I work on getting the pipeline back down. Yah, maybe I don't *need* to brew this weekend, but I *want* to because I still need to dial in the new mash tun/false bottom combo. First world problems, yes I know.

Bottled the Bohemian Pilsner at the city house. Four 500 ml bottles and 20 12 oz bottles. And a sample.

After this is carbed I’ll put it in the crawl space for a month to lager. I think I’ll call it “Cellar Dweller”.

After this is carbed I’ll put it in the crawl space for a month to lager. I think I’ll call it “Cellar Dweller”.

Just made a 2 liter yeast starter for my Kolsch that I am brewing on Saturday.

John

John

- Joined

- Feb 19, 2017

- Messages

- 979

- Reaction score

- 1,238

First keg sample of a split batch cyser experiment now that the weather is cool and my garage is below 60F. So, I tried doing a cyser using a mix of Sake #9 and Nottingham yeast. It's been a while so completely forgot that for about the first month, Sake #9 produces a "pukey" taste that disappears but is *cough cough* unpleasant *cough cough* while it lasts. I shall be sticking with Notty in the future and write off my previous Sake and Sake yeast experiments as "been there, done that." I also used a can of cranberry juice concentrate to add some tartness, but methinks that didn't work.

Half the batch has some vodka soaked oat chips in the fermenter. Just a half assed experiment to see what a "handful" of lightly toasted oak chips will do for a cyser.

I've tried the Hop Swarm Dry Hopped Mead by Havoc (Groennfell Meadery of Vermont). Inspired by the concept and combined with a palate that does not agree with the C hops, I therefore spunded half the batch at OG 1010 and dry hopped with Bramling Cross. Unfortunately, it barely carbonated and now is under CO2 to get to a decent level. This is what I'm sampling now. It's drinkable. Still somewhat sweet so hasn't fermented all the way out. See how it carbonates up. The Bramling Cross is a light touch but improves on the straight cyser. Will need to experiment further.

Still somewhat sweet so hasn't fermented all the way out. See how it carbonates up. The Bramling Cross is a light touch but improves on the straight cyser. Will need to experiment further.

Have 4 gallons of Costco fresh pressed cider + 5# Costco honey + notty in a different fermenter that's dropped from 1080 to ~1040. It is showing really good promise at this stage. Will split this one up as well when closer to 1010.

Half the batch has some vodka soaked oat chips in the fermenter. Just a half assed experiment to see what a "handful" of lightly toasted oak chips will do for a cyser.

I've tried the Hop Swarm Dry Hopped Mead by Havoc (Groennfell Meadery of Vermont). Inspired by the concept and combined with a palate that does not agree with the C hops, I therefore spunded half the batch at OG 1010 and dry hopped with Bramling Cross. Unfortunately, it barely carbonated and now is under CO2 to get to a decent level. This is what I'm sampling now. It's drinkable.

Have 4 gallons of Costco fresh pressed cider + 5# Costco honey + notty in a different fermenter that's dropped from 1080 to ~1040. It is showing really good promise at this stage. Will split this one up as well when closer to 1010.

Tested the WF lager from last weekend; tastes just okay, just needs to crash to get where I want it. Milled grain for tomorrow's american strong brewday (18+lbs, holy crap, I am covered in grain dust) and soon will tap the Holiday ale that's 4 weeks old now and should be carbed up enough after 1.5 weeks of slow carbing. If it's good I'll enjoy a few pints before relegating it to the back of the kegerator to age out a few more weeks before bottling a few for gifts, and quaffing plenty on the soon-to-come cold nights. Long good week at work=mama gets Friday night to enjoy her homebrew. Dinner? what's that? Oh, just go toss something from the freezer in the microwave. I'm busy here.

BrewMan13

Whole Nother Level Brewing

Got a yeast starter going and all of the other normal prep-work before brewday tomorrow. Forecast temp keeps dropping every time I look - gonna be a chilly one! Also kegged the adambier. Definitely needs some time to age, but that was always the plan.

ive only played with vanilla once in a porter and was curious when/for how many days you generally add yours? I’m hoping to brew an oatmeal stout again this winter and wanted to add vanilla this time.The vanilla beans I ordered came in today. Tonight I scrapped and chopped them up (five of them) to soak in some bourbon. These will be added to my imperial stout I plan to brew next weekend along with the bourbon soaked oak chips. The beer will sit on these after fermentation is complete.

This is my first time using vanilla beans and it will be in an imperial stout. I figured I would toss the vanilla and oak chips both soaking in bourbon into a mesh cylinder into a keg once the beers done fermenting. Then rack the beer into the keg and let it sit till September or October with the vanilla and oak chips. Then I’ll add the coffee and start carbonating it next fall to enjoy.ive only played with vanilla once in a porter and was curious when/for how many days you generally add yours? I’m hoping to brew an oatmeal stout again this winter and wanted to add vanilla this time.

The oak chips have been soaking in bourbon since October 2019.

TheEagleRising

Well-Known Member

- Joined

- Aug 20, 2018

- Messages

- 1,632

- Reaction score

- 4,317

Cleaned some kegs and filled them up. Cleaned the fermentors and started thinking about what's next, hoping to get a brew in tomorrow.

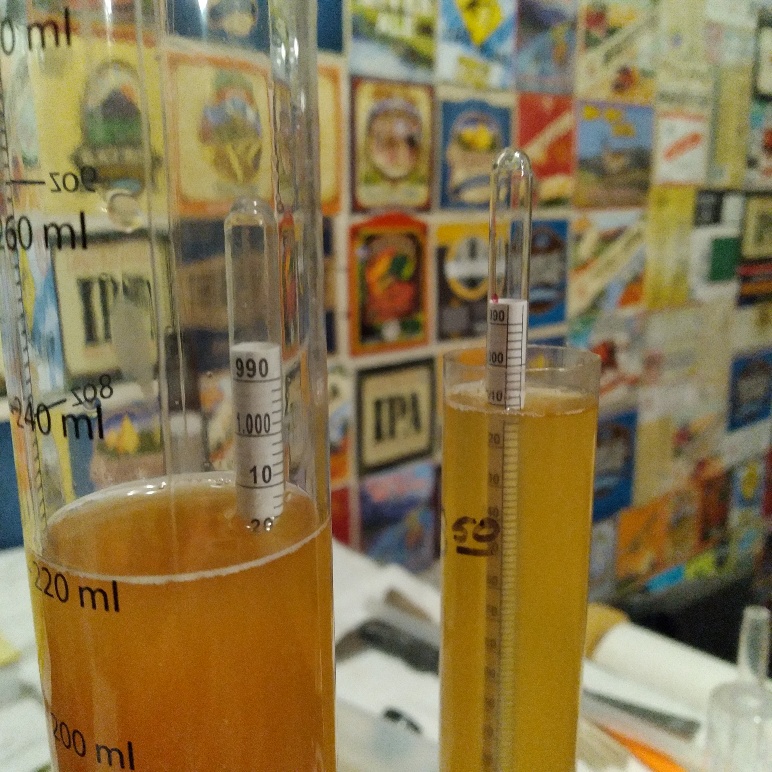

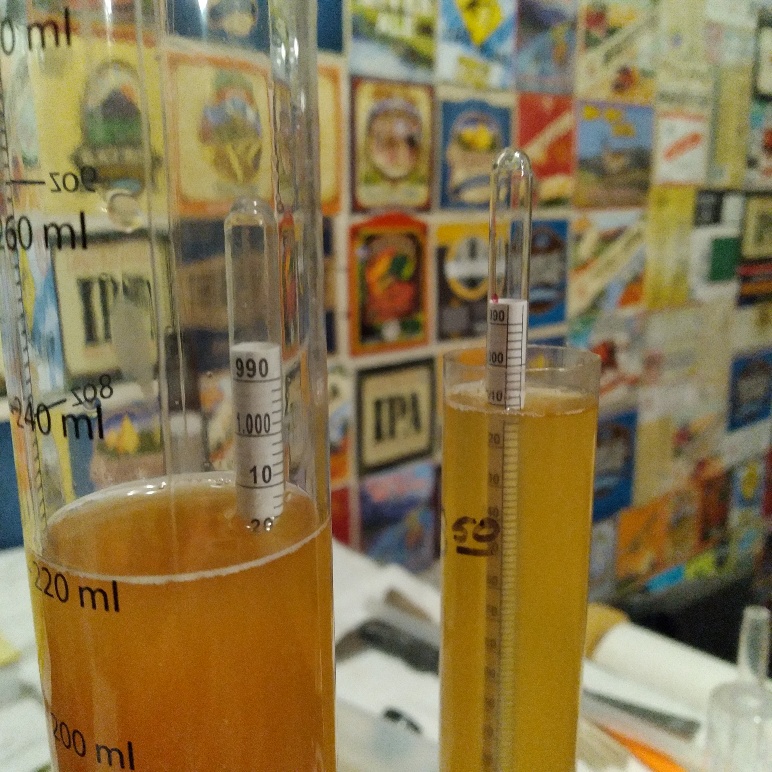

Proof of ferment and typical pre-kegging clarity, WLP041 Best bitter 11days(3 or 4 longer than normal) without a crash. Realized I normally take my hydro samples from the bottom of the fermentor after the keg is filled so that might explain some haziness. This was from the beginning of transfer, chill time will clear it up.

Proof of ferment and typical pre-kegging clarity, WLP041 Best bitter 11days(3 or 4 longer than normal) without a crash. Realized I normally take my hydro samples from the bottom of the fermentor after the keg is filled so that might explain some haziness. This was from the beginning of transfer, chill time will clear it up.

Pulled FG samples from the Pale Ale and Cali Common I brewed a couple of weeks ago. Probably kegging tomorrow. The pale (on the left) finished at 7.2%, the Common at 5.5%.

Would normally expect a california common to be closer in color to the pale. I brew my california common as a blonde sometimes too, originally called it an uncommon blonde then switched to Barbary Coast blonde.

I cheated a bit with that recipe. I normally use 90% two-row and 10% caramel 40. The color ends up about the same as the pale in the picture.Would normally expect a california common to be closer in color to the pale. I brew my california common as a blonde sometimes too, originally called it an uncommon blonde then switched to Barbary Coast blonde.

I was using up some small amounts of grain so, for this batch, I used about 45% pale ale malt, 45% Vienna, and 10% caramel 120. I should have used a little more caramel malt to get the appropriate color.

I’m not big on brewing strictly to style. I’ll have beer, and it will probably taste pretty much like the Cali Common recipe I’ve been brewing for 7 or 8 years now, if the FG sample is any indication.

shrews824

Well-Known Member

Brewed a 4 gallon APA today. OG hit 1.050.

- Joined

- Jan 28, 2013

- Messages

- 3,926

- Reaction score

- 3,026

Unpacked my ingredients for my brew day next Saturday, put the hops in the freezer, yeast in the fridge and started finding all the stuff needed for brew day!

That is the cool thing about homebrewing, you can brew beer how you want if you want.I cheated a bit with that recipe. I normally use 90% two-row and 10% caramel 40. The color ends up about the same as the pale in the picture.

I was using up some small amounts of grain so, for this batch, I used about 45% pale ale malt, 45% Vienna, and 10% caramel 120. I should have used a little more caramel malt to get the appropriate color.

I’m not big on brewing strictly to style. I’ll have beer, and it will probably taste pretty much like the Cali Common recipe I’ve been brewing for 7 or 8 years now, if the FG sample is any indication.

I brew some beers to style guidelines to enter into contests, but covid pretty much shut that down around here. Lately my grain bill for most of my beers is almost all base malt, then I change up hops to make them different.

I have a bunch of darker crystal and roast malts that have been sitting for a while, I really need to brew some stouts or porters to clear old inventory.

2nd run of the new improved mash tun went superbly well today, except this time went too high on the strike temp and mash got up to 156 (oops). No matter, didn't hurt it, and managed to squeak 1.087 SG out of 18lbs of grain. Then I racked it onto a huge Notty yeast cake that had just finished my IPA; three hours later it had a 3" krausen and the blowoff bottle has a huge starsan afro. Garage still smells great from today's brewday, and the ferment fridge smells great too. Kegged off last WF lager and aforesaid Sabro/Citra IPA, did some fiddling with the co2 lines in the kegerator so can slow-carb both of them. Good day.

Similar threads

- Replies

- 66

- Views

- 2K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)