What was your solution?

had the needle valves going opposite flow

What was your solution?

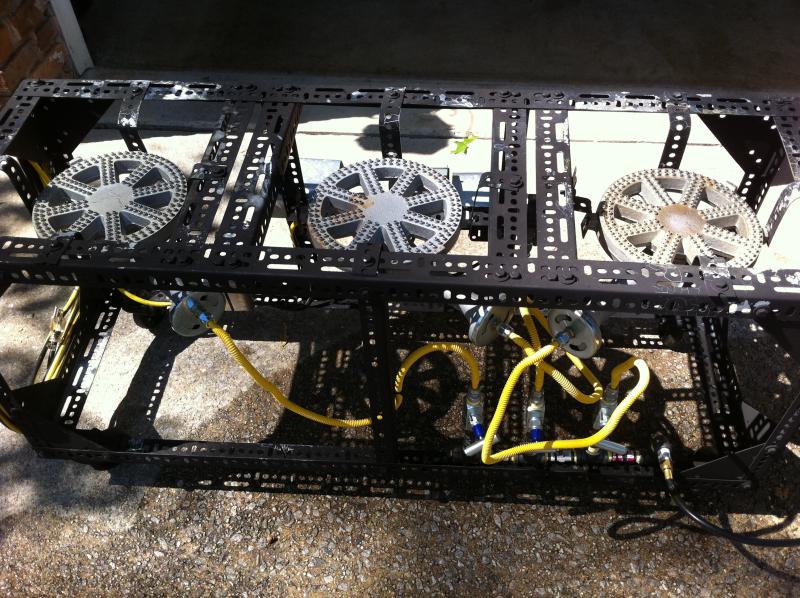

I have not had a chance to hard plumb my burners in yet. The bigger burners in the earlier posts are 30 bucks from agrisupply.com and the 6 inch burners are 10 bucks. It puts out 70k btu's so figure it'll be enought to boil a 10 gallon batch without any problems.

Has anyone used these burners? Link to the $30 burners I wonder how well they work (how long to boil, efficiency, etc).

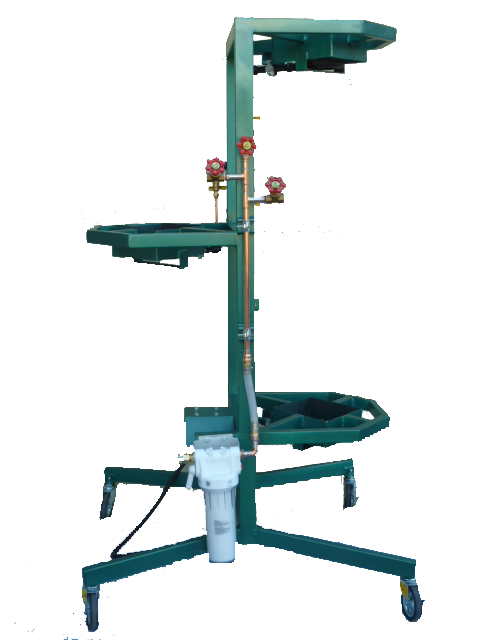

Saw the link for the Wallace stand a few weeks ago, but just stumbled on this thread yesterday. Fantastic info guys!

After finding the Wallace page, I went straight to Google Sketchup. I want to use the slotted angle iron to create a 4-tier system to help my 87-year old lower back. I also am content to stay at 5 gallons. So I think, based on the measurements of my current 9 gallon Bayou Classic kettle and 52 qt rectangle Igloo cooler that I can pull off a compact gravity fed system.

A few questions...

1) Does this look stable? The hot liquor will only top out at about 5.5' high. I plan on filling that with a hose. If there are 8 or so gallons of weight up there and negligible weight on the other tiers, but the casters are locked, it won't make the low side flip up, will it?

Thoughts or suggestions before I start buying stuff? Thanks!

Ahhh..Google sketchup! Wow..that looks like a great program..Not too far from Solidworks (visually anyway). Very cool! design and all!

I have a feeling that you are asking about the stability because it is making you nervous? That is a good intuition to have..Personally..I would follow that and make it either wider (looks like 1'2" wide) or shorter. I don't know if it makes sense..But you are almost 4x the width in height(granted, the height isn't constant). It probably would not take much to tip..

the base is much too narrow for the height

on a single tier the minimum depth should be about 18"

you have multiple tiers, the base footprint should compliment the height

The thirty dollar burners from agrisupply work great, have three on my setup. Only thing to consider is its somewhat hard to keep a constant temp on my direct fired mash tun. I often heat to desired temp, turn off burner, repeat during mash. One work around would be to get two large burners for your kettle and hlt and a small burner for your mlt.

2) McMaster-Carr has the green powder coated steel. Has anyone used or seen this?

Its On. I ordered the Green Stuff!

Products

Line Quantity Item Ships Unit price Total

1 2 each 4664T72 Steel Perforated Flat and Angle Framing Angle, Green Powder-Coated, 1-5/8" X 1-5/8", 6'L today $12.02 each 24.04

2 6 each 4664T74 Steel Perforated Flat and Angle Framing Angle, Green Powder-Coated, 2-3/8" X 1-5/8", 6'L today $14.89 each 89.34

3 16 each 4664T22 Steel Perforated Flat and Angle Framing Galvanized Steel Corner Plate, 6" X 6" X 6" today $2.41 each 38.56

4 2 packs 4664T61 Steel Perforated Flat and Angle Framing Hardware: Zinc-Plated Steel Bolts W/Nuts & Washers, packs of 50 today $6.45 pack 12.90

Merchandise total

$164.84

How much was the shipping, if you don't mind me asking?? McMaster doesn't really like to give that info out until you've pretty much placed your order. I'm on the fence about wood vs metal for an E-brewery. I like the look and expandability of the erector set build, but cost (with shipping) might argue for wood. . . thanks

Its On. I ordered the Green Stuff!

Products

Line Quantity Item Ships Unit price Total

1 2 each 4664T72 Steel Perforated Flat and Angle Framing Angle, Green Powder-Coated, 1-5/8" X 1-5/8", 6'L today $12.02 each 24.04

2 6 each 4664T74 Steel Perforated Flat and Angle Framing Angle, Green Powder-Coated, 2-3/8" X 1-5/8", 6'L today $14.89 each 89.34

3 16 each 4664T22 Steel Perforated Flat and Angle Framing Galvanized Steel Corner Plate, 6" X 6" X 6" today $2.41 each 38.56

4 2 packs 4664T61 Steel Perforated Flat and Angle Framing Hardware: Zinc-Plated Steel Bolts W/Nuts & Washers, packs of 50 today $6.45 pack 12.90

Merchandise total

$164.84

20 year old green powder coated angle iron

Anyone have a list of gas parts to buy to put together burners?

thanks for the pics and links. but what about needle valves to control the exact flow to the burners? I thought ball valves were mostly used for on/off gas applications?

So it looks like I was charged $204...14 of that was tax.....so 25 bucks for shipping.....Not great but could be worse(Cheaper than a welder)

[/url]