Well I made a bit of progress today as the first real lake effect snow hit is today. Have everything on hand or ordered for the build except for the stand still debating wood or metal? Built the manifold for MT today out of 1/2" copper pipe and fittings, will complete the line out to ss ball lock once I have those parts.

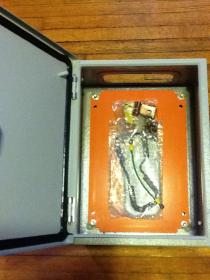

View attachment 1

View attachment 1

I just have all the fittings push fitted without any solder. I used a Rotozip for all the cuts and slots. Nice and tight fits well into the MT. Each long leg are @8" and the end one with the tee heading out is 7.5" to accommodate for the space of the tee.

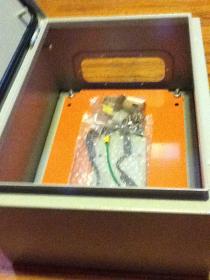

View attachment 1

View attachment 1

I just have all the fittings push fitted without any solder. I used a Rotozip for all the cuts and slots. Nice and tight fits well into the MT. Each long leg are @8" and the end one with the tee heading out is 7.5" to accommodate for the space of the tee.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)