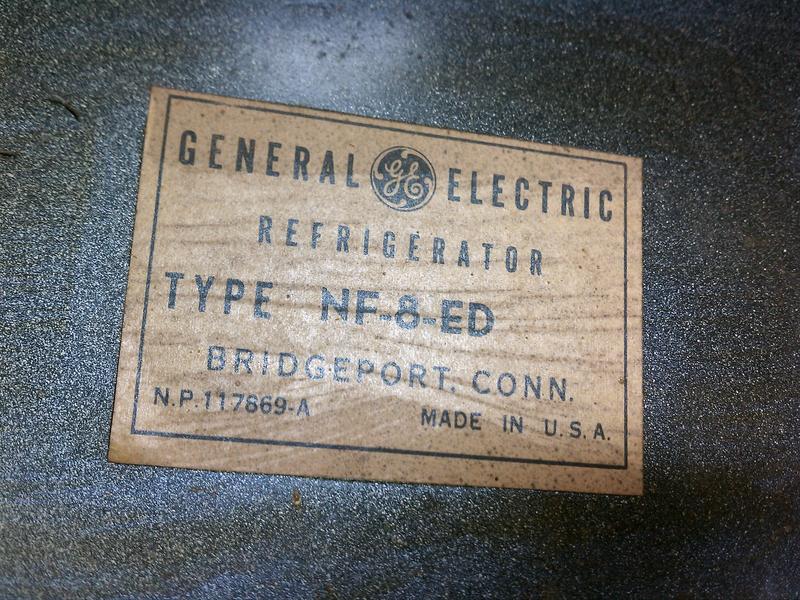

A couple weeks back, I acquired a 1950's GE refrigerator for $75 off craigslist. Happily, it's in great shape and everything works! I'd like this ol' box to continue working well for years to come, so I'm going to give it some love.

The entire thing is being disassembled to make a full cleaning and repainting easier. The unneeded shelf mounting hardware will be removed. A large amount of the wiring is being replaced. It's getting sanded down to remove any scattered surface rust. Any small dings will be filled with bondo and sanded. The whole thing will be primed and receive a few coats of white Rustolium appliance enamel spraypaint. A new gasket will be added to help seal it. At some point, I'll be adding some black and red accents.

Here are a few before and after deconstruction pics

[Descriptions below photos]

Even without cleaning, this thing is in great shape. I was afraid I wouldn't be able to take it apart much, as I didn't want to stress connection on the old cooling lines.

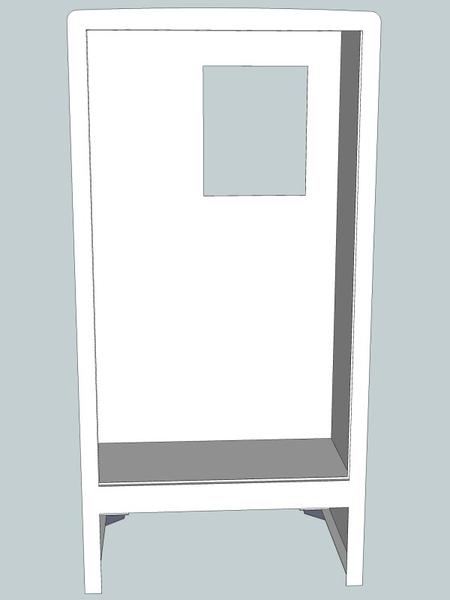

As it turns out, the entire refrigeration system is put together as a separate piece that can be dropped in to the chassis.

The back plate contains the condenser lines and serves as a mount point for the compressor and electronics.

From the top of the compressor runs a copper line to an access panel on the back of the fridge.

After removing some insulation and plates, the evaporator can pass through the hole in the back of the chassis.

Well, that's all I was able to get done this afternoon. Not bad for a first day, though.

The entire thing is being disassembled to make a full cleaning and repainting easier. The unneeded shelf mounting hardware will be removed. A large amount of the wiring is being replaced. It's getting sanded down to remove any scattered surface rust. Any small dings will be filled with bondo and sanded. The whole thing will be primed and receive a few coats of white Rustolium appliance enamel spraypaint. A new gasket will be added to help seal it. At some point, I'll be adding some black and red accents.

Here are a few before and after deconstruction pics

[Descriptions below photos]

Even without cleaning, this thing is in great shape. I was afraid I wouldn't be able to take it apart much, as I didn't want to stress connection on the old cooling lines.

As it turns out, the entire refrigeration system is put together as a separate piece that can be dropped in to the chassis.

The back plate contains the condenser lines and serves as a mount point for the compressor and electronics.

From the top of the compressor runs a copper line to an access panel on the back of the fridge.

After removing some insulation and plates, the evaporator can pass through the hole in the back of the chassis.

Well, that's all I was able to get done this afternoon. Not bad for a first day, though.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)