you probably need a different reader, but my quick search didn't come up with one that looked like you could just swap out.is there some type of tweak I can do or is there a better quality reader ??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[Version 2 Release] RaspberryPints - Digital Taplist Solution

- Thread starter skemp45

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Benjamin Carlisle

Active Member

- Joined

- Jan 23, 2019

- Messages

- 32

- Reaction score

- 5

@Benjamin Carlisle Looks like your settings and configuration seems reasonable.

How long is the wire from the meter to the Pi? Do you have a pullup resistor on the data line?

How big are the ghost pours? Do they always happen or is random?

Does it happen on every tap or just one?

Have you tried swapping flowmeters and do the problem follow the meter or the tap?

10ft cat5 wires (3 for flowmeter / 2 for valve) with no pullup resister

I only have 1 tap installed right now.

I have not swapped.

The pours are small to very large...mostly large 50 -300 oz after conversion. random...but consistent. The flowmonitor service also fails most days.

What size should the pull up resister be ? would it change with cable length ??

Benjamin Carlisle

Active Member

- Joined

- Jan 23, 2019

- Messages

- 32

- Reaction score

- 5

you probably need a different reader, but my quick search didn't come up with one that looked like you could just swap out.

Do you use RFID ? what is your experience?

I believe the recommended value for the pull up is 2.2K, would not change cable length.10ft cat5 wires (3 for flowmeter / 2 for valve) with no pullup resister

I only have 1 tap installed right now.

I have not swapped.

The pours are small to very large...mostly large 50 -300 oz after conversion. random...but consistent. The flowmonitor service also fails most days.

What size should the pull up resister be ? would it change with cable length ??

[Version 2 Release] RaspberryPints - Digital Taplist Solution

Even if you don't have taps setup for the other meters it might be helpful to still hook them up dry to see if you get random pours from those meters too.

The connections in your valve box look modular could try swapping cables to see if problem follows a cable.

Could try swapping flowmeters to try and isolate it too.

Maybe use an ohm meter or voltmeter to make sure you don't have any shorts or open in your connection. A short to another pin is more likely.

Last edited:

I am not running rand's code actively, but I did a testbed of some of the early code and had issues with using pin 13. If it is easy rewire maybe try a different pin.Ok...thank you so much for asking the questions...you believed me when I said...I don't know where to start.....

so...I have 4 swissflow with valves...

keg---2 foot 1/4' hose ---valve/flowmeter ---12 foot trunk line w/glycol to tap.

pour message delay 300

pour trigger count 400

kick trigger count 500

update trigger count 350

pour shutoff count 0

valve on time 2

number of taps 4

did calibration...and got 21865 count per gallon....that part is awesome and consistent...

I don't see any air at all...

Hope the pictures help.

@RandR+ are there any arduino pins that should be avoided?

Benjamin Carlisle

Active Member

- Joined

- Jan 23, 2019

- Messages

- 32

- Reaction score

- 5

I am not running rand's code actively, but I did a testbed of some of the early code and had issues with using pin 13. If it is easy rewire maybe try a different pin.

@RandR+ are there any arduino pins that should be avoided?

pin 13 is connected to RPi not arduino...it's for the valve

I use the same RFID reader and I have to press the card against it to register. Mostly because the cards are passive meaning they get their power from the RFID reader and power doesn't travel that far yet.Do you use RFID ? what is your experience?

I mounted mine to the keezer collar by making a rectangle hole for the pins and wires to go through, maybe not the best looking but highly functional

Attachments

There was one pin I had issues with on the alamode I think it was 13 trying to get the LED to blink, but that also may have been when I was working on the RFID logic because 13 is also the SCK.are there any arduino pins that should be avoided?

Alamode has a few no-go pins imo.

0 & 1 are tied up with the uart, of course.

2 is reliable, been using it for years.

3 is used for the Alamode TOY clock (PD3_SQW) square wave output. I had trouble with that one as I installed the TOY clock support.

4 should be ok. I thought I had a problem with it on my original build back in May 2014 so I skipped that one, never went back.

5 through 9 are bulletproof, which with 2 are enough for my six taps and I've been using those for 6+ years.

10, 11 and 12 are connected via translator to the RPi SPI signals SS, MOSI and MISO, but those are only enabled if the jumper mentioned below is installed. Otherwise they should work fine.

13 is indeed the "Blink" gpio and is also the translated RPi SPI clock SCK if the "enable communication" jumper for the translator chip is enabled. If jumper isn't installed it should work ok though the LED blinking might be distracting

I would urge folks considering a new build to not use the Alamode unless they are space constrained and need to go "up". The price is ridiculous compared to being able to pick up functionally legit R3 Uno clones for $5, and it's a bit awkward to use compared to an Uno spaced to one side of the RPi...

Cheers!

0 & 1 are tied up with the uart, of course.

2 is reliable, been using it for years.

3 is used for the Alamode TOY clock (PD3_SQW) square wave output. I had trouble with that one as I installed the TOY clock support.

4 should be ok. I thought I had a problem with it on my original build back in May 2014 so I skipped that one, never went back.

5 through 9 are bulletproof, which with 2 are enough for my six taps and I've been using those for 6+ years.

10, 11 and 12 are connected via translator to the RPi SPI signals SS, MOSI and MISO, but those are only enabled if the jumper mentioned below is installed. Otherwise they should work fine.

13 is indeed the "Blink" gpio and is also the translated RPi SPI clock SCK if the "enable communication" jumper for the translator chip is enabled. If jumper isn't installed it should work ok though the LED blinking might be distracting

I would urge folks considering a new build to not use the Alamode unless they are space constrained and need to go "up". The price is ridiculous compared to being able to pick up functionally legit R3 Uno clones for $5, and it's a bit awkward to use compared to an Uno spaced to one side of the RPi...

Cheers!

Benjamin Carlisle

Active Member

- Joined

- Jan 23, 2019

- Messages

- 32

- Reaction score

- 5

This was pour history last night after I did "good" pour once....

Why so high...it can't really be flow...can it ?

Why so high...it can't really be flow...can it ?

| 2020-12-23 00:25:00 AM | 2 | Loon Lake Porter | 89.41 | ||

| 2020-12-23 00:07:49 AM | 2 | Loon Lake Porter | 66.68 | ||

| 2020-12-22 23:48:54 PM | 2 | Loon Lake Porter | 16.33 | ||

| 2020-12-22 20:48:47 PM | 2 | Loon Lake Porter | 86.28 | ||

| 2020-12-22 20:44:55 PM | 2 | Loon Lake Porter | 11.35 | ||

| 2020-12-22 20:38:13 PM | 2 | Loon Lake Porter | 69.69 | ||

| 2020-12-22 19:36:47 PM | 2 | Loon Lake Porter | 252.21 | ||

| 2020-12-22 18:37:48 PM | 2 | Loon Lake Porter | 250.67 | ||

| 2020-12-22 18:10:57 PM | 2 | Loon Lake Porter | 68.04 | ||

| 2020-12-22 17:48:40 PM | 2 | Loon Lake Porter | 16.73 | ||

| 2020-12-22 14:39:29 PM | 2 | Loon Lake Porter | 13.12 | Benjamin |

Last edited:

Benjamin Carlisle

Active Member

- Joined

- Jan 23, 2019

- Messages

- 32

- Reaction score

- 5

Does it matter which side i put the resistor on? ie. closer to meter or closer to Arduino, knowing there is 10 ft between.

I would put it close to the flowmeter if it is easy to do. There is a weak pullup in the arduino so you are protected from a floating input in case the meter got disconnected. I think some of the flowmeters had pretty long cables on the meter so the actual location might not be too critical.

If you have a voltmeter it might be helpful to measure the voltage at the arduino pin when idle.

If you have a voltmeter it might be helpful to measure the voltage at the arduino pin when idle.

Well, after much tinkering, I’ve got my RPints back up and running. Thank you, @RandR+, for all the help in getting it set up!!

Here’s a video of it in action.

Now to BACKUP my card in case my card goes corrupt again and I lose all my customizations!! Thanks again!

Thanks again!

Here’s a video of it in action.

Now to BACKUP my card in case my card goes corrupt again and I lose all my customizations!!

Attachments

- Joined

- Sep 8, 2020

- Messages

- 139

- Reaction score

- 9

I am having this strange issue where the Tx and RX lights on my R3 stop alternately flashing and go solid on.

When this happens, no pours register. If I restart everything, it will work for random amounts of time. i.e. a week, a few hours etc.

Any idea what to even check or maybe someone has come across this issue as well.

I am using a breadboard with 2.2k resistors for pull up. I have also checked the resistance on all the flowmeter wiring, both through and not through all my cabling. The resistances are the same either way.

When this happens, no pours register. If I restart everything, it will work for random amounts of time. i.e. a week, a few hours etc.

Any idea what to even check or maybe someone has come across this issue as well.

I am using a breadboard with 2.2k resistors for pull up. I have also checked the resistance on all the flowmeter wiring, both through and not through all my cabling. The resistances are the same either way.

I would suspect a comms problem over the USB link, or insufficient power to the UNO.

If using USB for power, try using a 9V DC supply to the barrel connector instead. If already doing that, try a better USB cable...

Cheers!

If using USB for power, try using a 9V DC supply to the barrel connector instead. If already doing that, try a better USB cable...

Cheers!

- Joined

- Sep 8, 2020

- Messages

- 139

- Reaction score

- 9

I would suspect a comms problem over the USB link, or insufficient power to the UNO.

If using USB for power, try using a 9V DC supply to the barrel connector instead. If already doing that, try a better USB cable...

Cheers!

I am already powering off a separate power supply based on other recommendations in this thread, I am also on my 3rd USB cable. I can try that again.

Any suggestions on proven brands of USB cables?

Last edited:

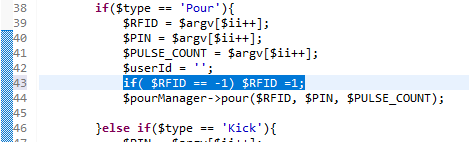

the Arduino sketch uses -1 to indicate no user RFID scanned. If you want to change it I would actually change the PHP to override -1 to 1 in includes/pours.php by adding this above line 43:Whenever I make a pour, userid -1 is credited with the pour. How and where do I change that so the default is userid 1

if( $RFID == -1) $RFID =1;

the Arduino sketch uses -1 to indicate no user RFID scanned. If you want to change it I would actually change the PHP to override -1 to 1 in includes/pours.php by adding this above line 43:

if( $RFID == -1) $RFID =1;

View attachment 713029

Awesome! Thanks for that! ....and if I do ever incorporate RFID, I don’t think I have to remove that line if I always want to take credit for a non-RFID pour.

Hi all

Happy new year! I thought from memory someone had printed up a case for the PIR on a 3D printer. Finally have myself a 3d printer and want to tidy up my setup and can't find anything through thread search. Anyone point me in the right direction?

Happy new year! I thought from memory someone had printed up a case for the PIR on a 3D printer. Finally have myself a 3d printer and want to tidy up my setup and can't find anything through thread search. Anyone point me in the right direction?

i am building my rpints system and plan to use the SF800 flow meters. I am using EVABarrier Double Wall Draft Tubing - 4 mm ID x 8 mm OD for my beer line. Can you point me in the right direction for what fittings I need for the flowmeters. Thanks in advance. Also thanks to RandR+ and others on the code and script. I ran the script and was a huge help. No way I would have figured all that out on my own.

For the SF800, the fittings for EVAbarrier tubing (which is 8mm or 5/16" OD) need to be 3/8" BSP female to 8mm (or 5/16") OD fitting.

For John Guest, that's part number PM450813E. When I was kitting up 13 months ago nobody carried this part in the USA.

For DMfit, that's part number AFAB0506C, which I found at freshwatersystems.com

Cheers!

For John Guest, that's part number PM450813E. When I was kitting up 13 months ago nobody carried this part in the USA.

For DMfit, that's part number AFAB0506C, which I found at freshwatersystems.com

Cheers!

thanks so much. found a 10 pack on amazon. Freshwater only had a 150 pack. Go figure. One more question. any issues or complications if I use these much cheaper flow meters by Digiten. Do I need to update any setting files in Rpints or install any resistors or just plug them into the right sockets on the ardunio?

Yes, you have to change the calibration value (essentially, what fraction of a gallon each tick represents).

I went right with the sf800s back in 2014 with the original 2.0.1 release and have no other experience, but there have been folks using similarly inexpensive meters to that shown that may be able to relate their settings...

Cheers!

I went right with the sf800s back in 2014 with the original 2.0.1 release and have no other experience, but there have been folks using similarly inexpensive meters to that shown that may be able to relate their settings...

Cheers!

- Joined

- Sep 8, 2020

- Messages

- 139

- Reaction score

- 9

its setup so that if the keg is on tap it cannot be set to empty otherwise you would have a empty keg on tap and that doesn't make sense and changing it from serving to something else doesn't remove it from the tap you have to do that from the tap list

I think I see why there are beers assigned.

I loaded the test data on install and then deleted the extra taps and kegs. Now I seem to be stuck where I go into the Keg maintenance and I don't have a way to select no beer on kegs #8 and 10...

I can see there are kegs assigned though via the Taps maintenance.

Attachments

- Joined

- Sep 8, 2020

- Messages

- 139

- Reaction score

- 9

I wonder if there is a data inconstancy here like the tap isn't assigned a keg but the keg is assigned a tap.

Can you run the following from the terminal (where <DatabaseName> is your database name, default is raspberrypints):

sudo mysql

use <DatabaseName>

select * from kegs where onTapId > 0;

that should return the kegs that think they are on tap. If the number of rows is not equal to the number you have configured on tap or you see a keg that you know you don't have on tap in the list then that is the issue

I also ran the sql you suggested and yes, there are kegs assigned to taps that are not correct.

| 1 | 1 | 1 | Cornelius | Super Champion | 84000259 | Pepsicola Bottling Co | Fargo, ND | NULL | SERVING | 41.4613 | NULL | 8.9960 | lb | 5.0000 | oz | 5.00000 | oz | 2.82672 | oz | 11.00 | psi | 42.00 | F | 1 | 15 | 1 | 0 | 2020-11-24 22:10:18 | 2021-01-07 15:09:23 |

| 2 | 2 | 1 | Cornelius | Super Champion | 81175979 | Joyce Bev | Washington D.C. | NULL | SERVING | 44.1495 | NULL | 8.1571 | lb | 5.0000 | oz | 5.00000 | oz | 3.25149 | oz | 11.00 | psi | 42.00 | F | 2 | 16 | 1 | 0 | 2020-11-24 22:10:18 | 2021-01-07 15:09:23 |

| 4 | 4 | 1 | Cornelius | Super Champion | 77320513 | Binghamton Btlg Co | (Unknown) | NULL | SERVING | 34.9994 | NULL | 8.1571 | lb | 5.0000 | gal | 5.00000 | oz | 3.20210 | oz | NULL | psi | 46.00 | F | 5 | 14 | 1 | 0 | 2020-11-24 22:10:18 | 2021-01-07 15:09:23 |

| 5 | 5 | 1 | Cornelius | Super Champion | 80224203 | Pepsi Btlg Co | Southern CA | Green handles | SERVING | 12.5100 | NULL | 8.1571 | lb | 5.0000 | oz | 5.00000 | oz | -0.06661 | oz | NULL | psi | NULL | F | 3 | 13 | 1 | 0 | 2020-11-24 22:10:18 | 2021-01-07 15:09:23 |

| 8 | 8 | 1 | Cornelius | Super Champion | 78143233 | Pepsi Cola Btlg Co | Parkersburg WVA | NULL | SANITIZED | 8.1571 | NULL | 8.1571 | lb | 5.0000 | oz | 5.00000 | oz | 0.00000 | oz | 12.00 | psi | 42.00 | F | 8 | 8 | 1 | 0 | 2020-11-24 22:10:18 | 2021-01-07 15:09:24 |

| 9 | 9 | 1 | Cornelius | Super Champion | 112620585 | Pepsi Cola Btlg Co | Aleghany, NY | Blue handles | SERVING | 29.0696 | NULL | 8.1571 | lb | 5.0000 | oz | 5.00000 | oz | 2.46465 | oz | NULL | psi | 42.00 | F | 4 | 11 | 1 | 0 | 2020-11-24 22:10:18 | 2021-01-07 15:09:24 |

| 10 | 10 | 1 | Cornelius | Super Champion | 82217553 | Pepsi Cola Seven Up | Mpls St Paul | NULL | SANITIZED | 8.1571 | NULL | 8.1571 | lb | 5.0000 | oz | 5.00000 | oz | 5.00000 | oz | NULL | psi | NULL | F | 10 | 10 | 1 | 0 | 2020-11-24 22:10:18 | 2021-01-07 15:09:24 |

How do I fix them?

from MySQL run this updateHow do I fix them?

update kegs set onTapId = null where onTapId is not null and onTapId not in (SeLECT id from taps WHERE active = 1);

that should reset the kegs to not be on tap anymore

- Joined

- Sep 8, 2020

- Messages

- 139

- Reaction score

- 9

from MySQL run this update

update kegs set onTapId = null where onTapId is not null and onTapId not in (SeLECT id from taps WHERE active = 1);

that should reset the kegs to not be on tap anymore

Seems to have fixed it. THANK YOU.

Do I need to be concerned that the 4 new kegs I just added to inventory are numbered 25-11, 25-12 etc?

In the mean time I looked into the other fields in the db and I assume that active = 1 means they are active? The test data I deleted has active = 0. So I am assuming that when the test data was 'deleted', it was really only making them inactive (active =0)?

Attachments

Last edited:

no its just <ID>-<LABEL> if there isn't a label then it will just be <ID>Do I need to be concerned that the 4 new kegs I just added to inventory are numbered 25-11, 25-12 etc?

Yes most things when they are deleted they are just marked inactive, this allows historical data without data inconsistencies

For the record, yes - when connecting flow meters to 5V-compatible devices, like an Uno or Mega...

Cheers!

Cheers!

Another noobs question. I am slogging my way through setting up my Rpints system and making great progress. I got my flow meter connected and working. I will be putting the temp sensor and PIR sensor once I get a breadboard.

I want to install a RFID and flow values to keep track of usage and put a control over highschoolers. Would these instructions be the way to connect the RFID Card reader?

Second, I know I need to get some 12 volt valves and a relay for each valve but where do I get the signal from to open the valves. I've searched hi and low and not been able to find where to connect the signal.

Lastly, I read and want to confirm its best if I have the flow sensor and valve as close to the key.

Thanks for everyones hard work on this great project. Hope to publishsome pictures of my keezer soon.

I want to install a RFID and flow values to keep track of usage and put a control over highschoolers. Would these instructions be the way to connect the RFID Card reader?

Second, I know I need to get some 12 volt valves and a relay for each valve but where do I get the signal from to open the valves. I've searched hi and low and not been able to find where to connect the signal.

Lastly, I read and want to confirm its best if I have the flow sensor and valve as close to the key.

Thanks for everyones hard work on this great project. Hope to publishsome pictures of my keezer soon.

I want to install a RFID and flow values to keep track of usage and put a control over highschoolers. Would these instructions be the way to connect the RFID Card reader?

HaHa! My answer was wrong...Thank you for asking the question, because you just saved me a ton of time because I would have done it wrong!

Last edited:

yes (I have to disagree with garzlok, the logic for RFID is in the PI not the UNO) I think those are the ones I followed, you dont need to do the commands as the setup did those for you. The example script may be helpful to make sure it is hooked up correctly.Would these instructions be the way to connect the RFID Card reader?

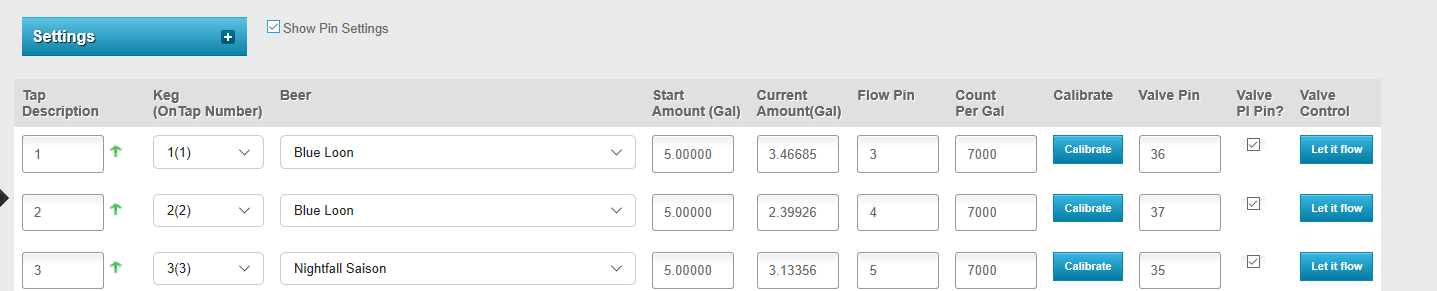

I use the Pi's higher numbered pins for the values signal (because alamode takes up the lower number), but you should be able to use the Shields pins also. Just make sure to check or uncheck Value Pi Pin depending on what you usewhere do I get the signal from to open the valves.

yes (I have to disagree with garzlok, the logic for RFID is in the PI not the UNO)

Whatever do you mean?

I guess I read a post that wasn't there....Whatever do you mean?

Or there is magic happening

I use the Pi's higher numbered pins for the values signal (because alamode takes up the lower number)

ok I found those settings after configuring to show valve control. I might not understand the use of the valves though. what triggers the valves to open. Is that the tagging of a rfid card or logging in of a user ? if so if there is no user logged into bpints are the valves are closed?

and in the configuration why would you have different pins for different taps. Wouldn’t all the valves open on all the lines

thanks

Yes the RFID opens the valves. There is also a button on the taps screen to trigger the valves to open, but then will stay open until you hit the button again. The RFID will timeout and close the valves if no pour is detected. Also this only works if you have normally closed valves otherwise the trigger will close them...what triggers the valves to open. Is that the tagging of a rfid card or logging in of a user ? if so if there is no user logged into bpints are the valves are closed?

I have each tap on its own valve that way if someone is pouring on tap 1 a new RFID scan is needed to allow pouring on tap 2 (for example). you could have all the taps on one pin if you wanted but that means they all are open while a pour is happening but they all will shut when that pour is stoppeddifferent pins for different taps.

have each tap on its own valve that way if someone is pouring on tap 1 a new RFID scan is needed t

thanks that helps but I’m still a bit fuzzy. If I have different valve pins how does brew pints know what valve to open After I tag a card

Similar threads

- Replies

- 6

- Views

- 4K

- Replies

- 21

- Views

- 3K