NewBrewer2025

Active Member

So I just got started into brewing, and I've started with extract kits. One of the first things I've learned about extract kits is the darker color they can give the brew. My first brew - a golden ale - hit the taste profile I wanted, but definitely came out a bit darker than I expected. And then I learned about the impact of LME on the color.

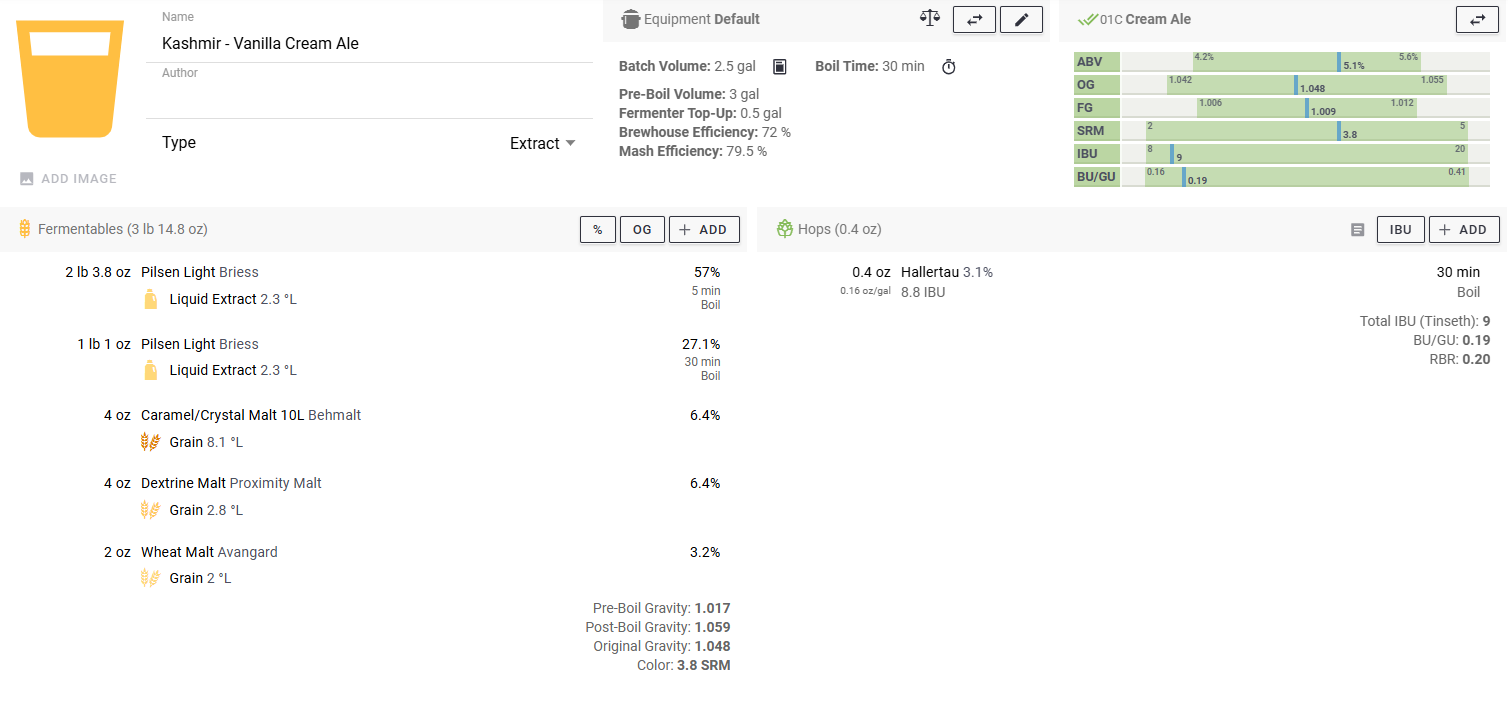

So, my next batch is going to be a Vanilla Cream Ale, and I was going to "experiment" a bit with some of the things I had learned. This is also going to be a 2.5 gallon batch, so I'll be doing a full volume boil.

Does this make sense? Am I adding enough LME in at the beginning? Is that boil time of 30 minutes instead of 60 going to be fine?

Thanks for any feedback!

So, my next batch is going to be a Vanilla Cream Ale, and I was going to "experiment" a bit with some of the things I had learned. This is also going to be a 2.5 gallon batch, so I'll be doing a full volume boil.

- I was going to add the LME in "batches." I was going to do about 33% at the beginning of the boil, and then the remainder with ~5 minutes left.

- I was thinking about shortening the boil time to 30 minutes. This is going to be a low IBU beer, so the bittering isn't as much of an issue here. I obviously have adjusted the amount of hops I will use due to the impacts of both of these decisions.

Does this make sense? Am I adding enough LME in at the beginning? Is that boil time of 30 minutes instead of 60 going to be fine?

Thanks for any feedback!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)