wsmith1625

Well-Known Member

For all the effort, why not just bottle?

Again, this takes Just the same effort of opening and closing a drawerFor all the effort, why not just bottle?

Why?I'm pretty much stubborn about not using force-injected CO2.

No, he has a useless fermenter if he dedicates it to serving his beer until it's empty. If he kegs he gets to brew again and never run out of beer!I guess if the OP switches to keg fermenters then he has a useless dedicated FV?

Don't they sell food grade bladders that can go inside kegs and force the liquid out under constriction?

Well, you can spund or prime in the keg so you only need store bought CO2 for serving.Flat beer sucks. Unless you bottle or use store bought CO2 yer gonna have flat beer.

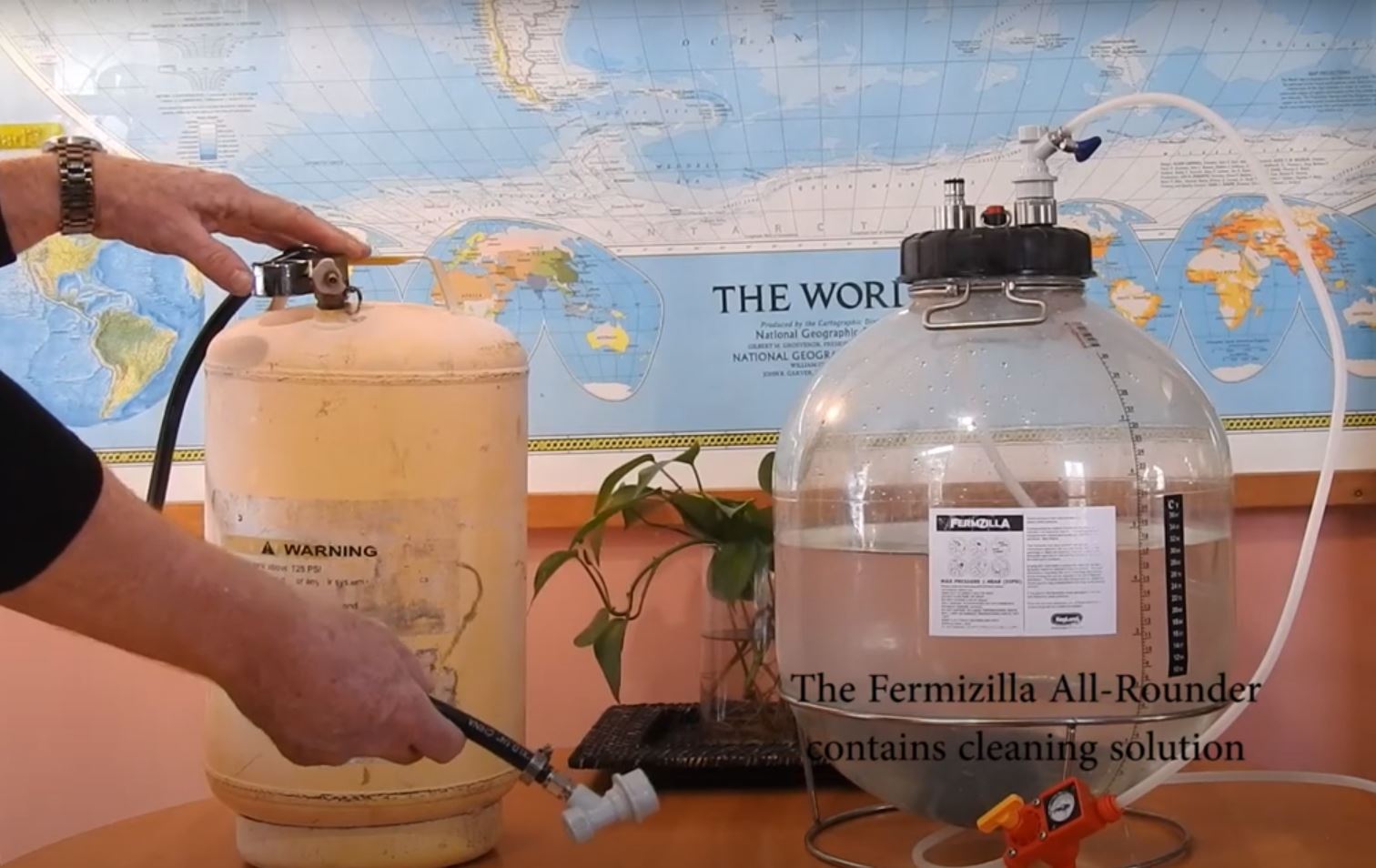

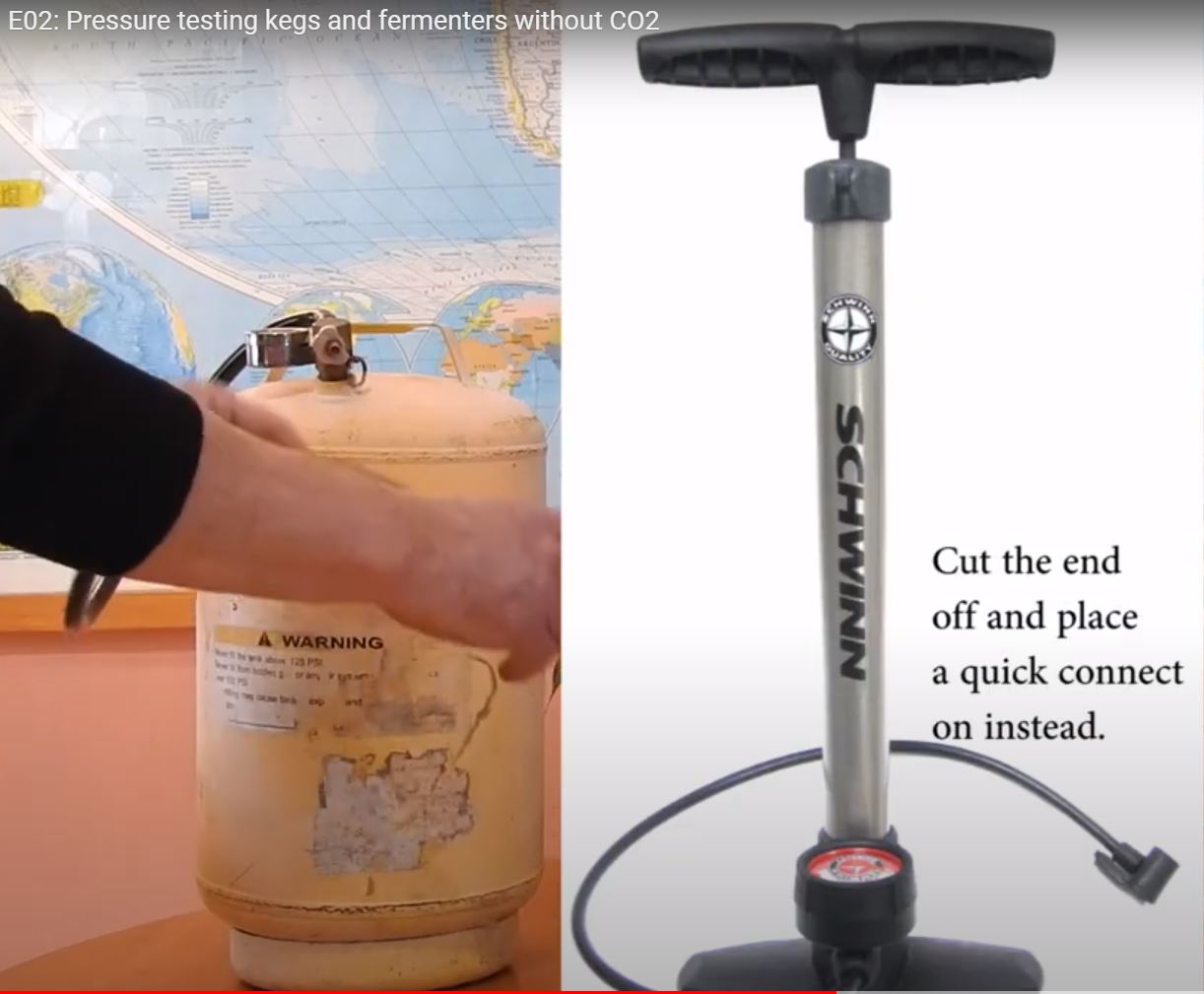

If you need to create some pressure in a tank with air, a pressurized portable air tank can be converted with a ball lock on it as so:I'm pretty much stubborn about not using force-injected CO2.

I think priming in a keg should be achievable even without a spunding valve. But there are plenty of folks around here who have much more experience with this than I do.So in these days I learnt a lot of things and words, help me clarify.

I can keg, prime with sugar, and (resign to) use a minimum amount of store bought CO2 to keep the beer carbonated. Is this achieved through a spunding valve?

No I mean, the constant CO2 level Is done with a spunding valve? Or maybe I should get a LPG regulator for thatI think priming in a keg should be achievable even without a spunding valve. But there are plenty of folks around here who have much more experience with this than I do.

Search the forums for those key words. You'll learn even more things and words, and might find that it's already been clarified.

A spunding valve is for spunding. It's like a pressure release valve that you can dial in a specific pressure to release, whereas PRVs are specific safety devices based on the vessel they are attached to.So in these days I learnt a lot of things and words, help me clarify.

I can keg, prime with sugar, and (resign to) use a minimum amount of store bought CO2 to keep the beer carbonated. Is this achieved through a spunding valve? That acts like a breather for a cask?

You probably already told me this, but consider that I didn't know what a spunding valve was until yesterday.

If you are using a CO2 tank, you'd use a regulator that is set to a specific pressure, so you don't try to push 600 PSI from your tank.No I mean, the constant CO2 level Is done with a spunding valve? Or maybe I should get a LPG regulator for that

Like the man said, a spunding valve is for spunding. It let's you set a maximum pressure level in the vessel during fermentation.No I mean, the constant CO2 level Is done with a spunding valve?

Yes, I misinterpreted what a spunding valve isLike the man said, a spunding valve is for spunding

I just meant to say that priming in a keg and spunding aren't necessarily the same thing. Priming in the keg is just like bottling in a very big bottle. You wait until final gravity is reached and then add enough sugar to produce the desired level of carbonation.

Or maybe I should get a LPG regulator for that

I don't see that working at all. As the beer leaves the keg, it will need to be replaced by air or co2, but there won't be any way for it to enter the keg. Either the beer won't flow or it will slowly glug out as air tries to enter the faucet while you pour the beer.Since we're here, tell me something.

I also considered gravity dispensing from the keg, but looking up online everyone says It's not possible due to the air/CO2 that should get in to let the beer out etc. and that's ok if we talk about the keg put on his side to emulate a cask.

But since corny kegs' tubes are removable and they can be stored upside down, will gravity fail if one removes the internal tubes and lets the beer drop Just by true and pure gravity?

I don't see that working at all. As the beer leaves the keg, it will need to be replaced by air or co2, but there won't be any way for it to enter the keg. Either the beer won't flow or it will slowly glug out the faucet as air tries to enter as the liquid tries to escape.

What mini-kegs are you talking about? Mine use CO2, as do all the one's I've seen.Mini-kegs don't use (as far as I know) nothing more then a spigot, and things fall down everyday everywhere...

The tin ones, party-kegs. Do they use CO2?What mini-kegs are you talking about? Mine use CO2, as do all the one's I've seen.

IOW, you have to let air in. BTW, those can also use CO2 cartridges with the right adapter.They use a vent bung that you pull out slightly before serving.