GriffinsRoost

Member

- Joined

- Sep 10, 2014

- Messages

- 20

- Reaction score

- 7

Got the freezer one year old, starting to source the parts. How long are the shanks have to be?

Any issues with defrosting?? Anything you would do differently from the original build?

I will be removing all the shelves so my plan is to have 10 taps (if it is possible) and 2 lines for carbonation so total will be 12 kegs. Also I am thinking of getting Inkbird controller. Where do you put your temperature probe??? I would guess in the middle of the fridge..

Thanks

No issues with the defrost. The cycle is short enough that you don't notice it with the thermal load.

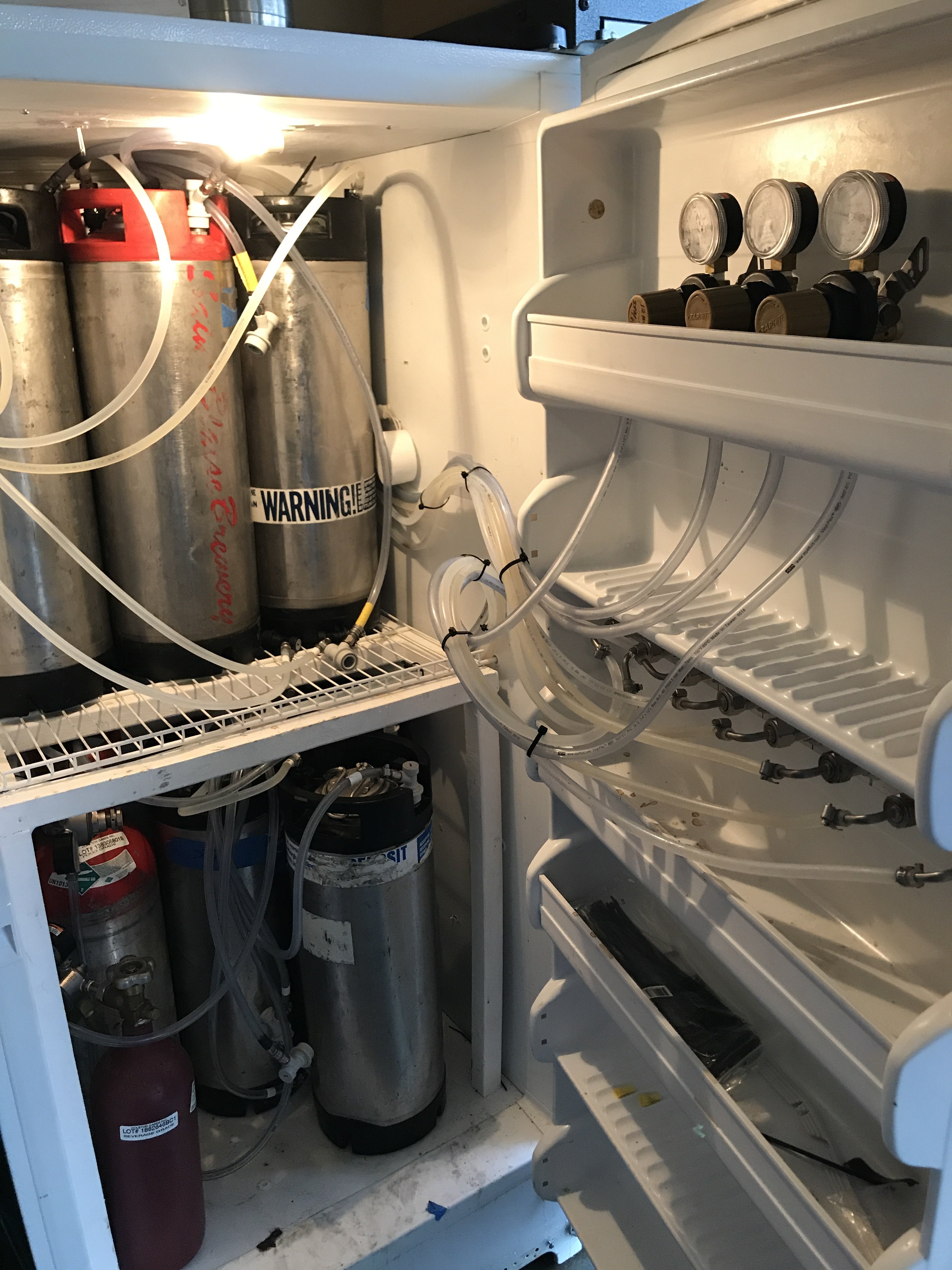

10 taps would be tough but do-able I would think. I am running 6, with shanks in place for 2 more. Doubt you could get 12 kegs in due to the hump at the back on the bottom. 6 on top max. I have been able to squeeze 4 in on the bottom a few times.

Shanks were 4- 1/8"

Edit: Forgot to comment on the inkbird. I would skip it. You can use the coarse adjust screw on the built in thermostat. Takes an hour or two to dial it in, but once you get it where you want, you are set. Saves $ and un-necessary modification.

Instructions here: https://www.homebrewtalk.com/forum/...tat-to-32f-eliminate-external-control.249612/

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)