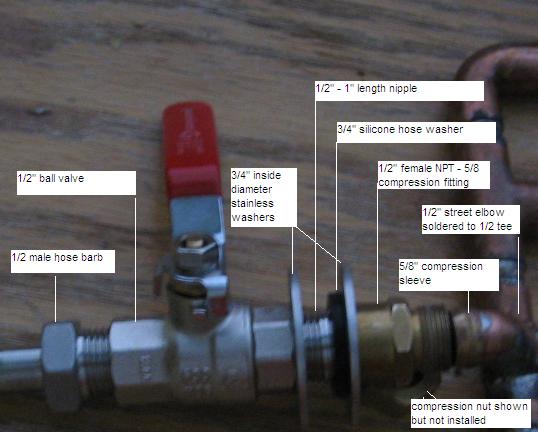

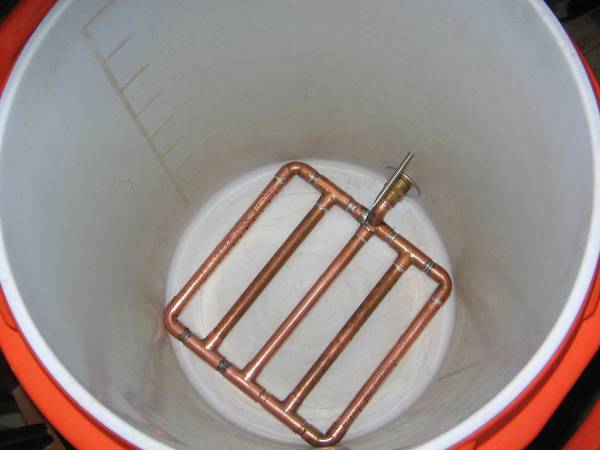

I just used a copper piece with 1/2" female side and a 1/2" normal side that connects to the manifold. I would imagine you could find something similar with a 3/8" female side.

I got all my parts at Lowes if that helps

That part I figured out - what I can't get is a watertight seal around where the manifold exits the cooler. The rubber washer that came with the cooler just isn't working. It looks like yours is out of steel on your build - what did you use?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)