Thanks for clarifying. I knew you would be the man to help!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unboxing the Nano from CO Brewing

- Thread starter pretzelb

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

Someone call my name?!?

That type of design @jahlinux posted above is passive and works well as long as you have a large enough vertical duct to carry the heat out. But if the heat cannot carry, a vent may not be enough. If the heat cannot escape and the tube is not cool enough to condense the liquid out, the heat will be trapped and the steam will not be pulled out enough. In my design, I use a water sprayer to provide the cooling locally. Obviously this is not as simple as the passive system but it assures the heat is pulled out and the steam condenses.

How much ducting do you think is necessary? I’ll be brewing in a basement and venting out a window about five to six feet above the kettle.

Should work!

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

What if I don't care about the heat and only want to trap the condensation? Will the CBS system pictured above work or do I need a vertical vent?Someone call my name?!?

That type of design @jahlinux posted above is passive and works well as long as you have a large enough vertical duct to carry the heat out. But if the heat cannot carry, a vent may not be enough. If the heat cannot escape and the tube is not cool enough to condense the liquid out, the heat will be trapped and the steam will not be pulled out enough. In my design, I use a water sprayer to provide the cooling locally. Obviously this is not as simple as the passive system but it assures the heat is pulled out and the steam condenses.

You cannot separate the two. Steam is hot and when you cool it, its vapor condenses. If you don't cool it, the condensate will not drop out (or not enough, at least). So either the steam needs to be vented, or its heat pulled out and condensate drained, or a combination of both.

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

I guess I an confused on how the CBS one works

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$1.91

$29.95

Mastering Homebrew: The Complete Guide to Brewing Delicious Beer (Beer Brewing Bible, Homebrewing Book)

Goodwill Retail Services, Inc.

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

I'm going to move my 25 gal Down Under into the basement and vent it out the window. I really like the idea of the Colorado Brewing Systems hood. BrunDog do you think I have enough vertical run for it to work properly? It's really only going to be about 3 or 4 feet.

Last edited:

Yes, that should be ok. Just know any situations where a pressure differential may not allow the passive exhaust to work. So make sure that there is no desire for air from outside to come inside via the vent. If the vent is sealed to the window, that possibility increases. Having the window open with the exhaust exiting through it would be best. Not sure what that would mean for the winter

I guess I an confused on how the CBS one works

The CBS (on most pro style vents) works passively. The hot steam rises up the pipe. Steam that makes it out... makes it out which is good. Some steam which condensed in the tube drains back down and out the drain. That is very hot (near boiling) water that needs to be drained.

The one I designed for HB scale uses spraying water to condense the steam and all of it is drained. No vent needed but requires water, sprayer, etc.

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

Yes, that should be ok. Just know any situations where a pressure differential may not allow the passive exhaust to work. So make sure that there is no desire for air from outside to come inside via the vent. If the vent is sealed to the window, that possibility increases. Having the window open with the exhaust exiting through it would be best. Not sure what that would mean for the winter

I could just stick the hose up into the open window. I was actually thinking of removing the window and inserting a plexiglass insert with a hole for the vent. But you bring up a good point about making sure there is no differential pressure between the kettle and the vent. There are other windows in the basement I could open to eliminate any DP. Glad to hear you don't think I'll have any issues. The hood is really expensive, $550.00. But I really like the idea of not having to run a fan during the boil.

Last edited:

You could just run a test with a duct tube in a kettle of boiling water sealed off with Saran wrap. Ultimately you need the T drain and the drain out the bottom. Think about how you will capture that... into a bucket or down your sink drain (remember it’s hot).

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

You could just run a test with a duct tube in a kettle of boiling water sealed off with Saran wrap. Ultimately you need the T drain and the drain out the bottom. Think about how you will capture that... into a bucket or down your sink drain (remember it’s hot).

I was thinking of just draining into a bucket. I will have a sink next to the kettle, just don't think it will be able to gravity drain into it. I'm thinking a five gallon bucket will work.

mcgimpkins

Well-Known Member

- Joined

- Feb 23, 2014

- Messages

- 201

- Reaction score

- 56

Brew Boss e-mailed this out back at the end of November: Condenser-Boss Accessory Port Mount Steam Condenser. You might be able to build one yourself, it is an interesting concept for those that don't have ventilation.

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

Brew Boss e-mailed this out back at the end of November: Condenser-Boss Accessory Port Mount Steam Condenser. You might be able to build one yourself, it is an interesting concept for those that don't have ventilation.

Thanks for the link. If I go without installing an exhaust fan this may be a better option. The only thing that concerns me is the way the grain basket has to rest on the kettle rim. To use the Condenser-Boss you need to install a gasket on the rim of the kettle. Maybe it's removable or I could try and come up with a way to install it on the lid instead of the kettle rim.

Last edited:

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

I am installing a version of this on a Nano 20 this Friday. I will be using a 1.5" T. I will post lots of photos and plan to do a boil test and have the results posted by Friday evening.

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

I am installing a version of this on a Nano 20 this Friday. I will be using a 1.5" T. I will post lots of photos and plan to do a boil test and have the results posted by Friday evening.

Awesome! Look forward to your results.

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

I am installing a version of this on a Nano 20 this Friday. I will be using a 1.5" T. I will post lots of photos and plan to do a boil test and have the results posted by Friday evening.

How are you connecting the steam condenser to the kettle?

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

How are you connecting the steam condenser to the kettle?

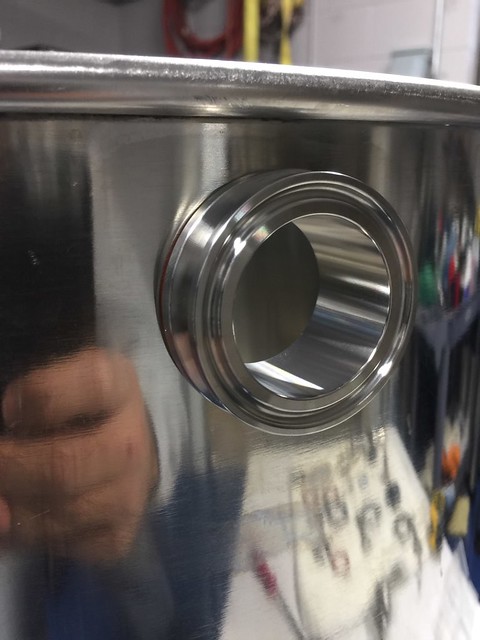

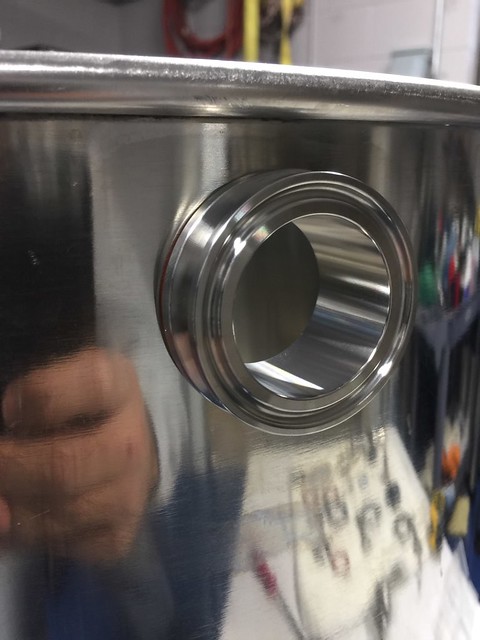

I am using a weldless 1.5 “ triclover flange!

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

weldless 1.5 “ triclover flange

Where did you get yours from? Seem like they are hard to find.

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

The only place I found it in stock was SS Brewtech

cyclonebeer

Well-Known Member

- Joined

- Nov 1, 2008

- Messages

- 112

- Reaction score

- 20

I really haven't spent much time digging into it yet, but a couple of points that strike me at first blush:I'm ready to spend the money as long as it will work. Anyone have any negative opinions about it?

You need to keep the lid on during the boil, so you can't monitor how vigorous your boil is. Probably not a big deal. Also, you have to remove the lid for hop additions, etc. I see the Brew Boss system has a sealed lid. Don't know about the CBS system. Again, probably not a real big deal. At any rate, it's a heck of a lot cheaper than installing hood, fan, duct work, etc. I know that from personal experience. I hired an HVAC tech, electrician, and carpenter to build my exhaust system. Ouch. Works like a charm however. If something like this had been around 3 years ago, I would have been on it like flies on a turd.

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

Wonder if something like this would work? http://www.ventafume.com/overhead-kiln-ventilation-systems-2/

Not sure what they charge but maybe it could be hung from the pulley connection?

Not sure what they charge but maybe it could be hung from the pulley connection?

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

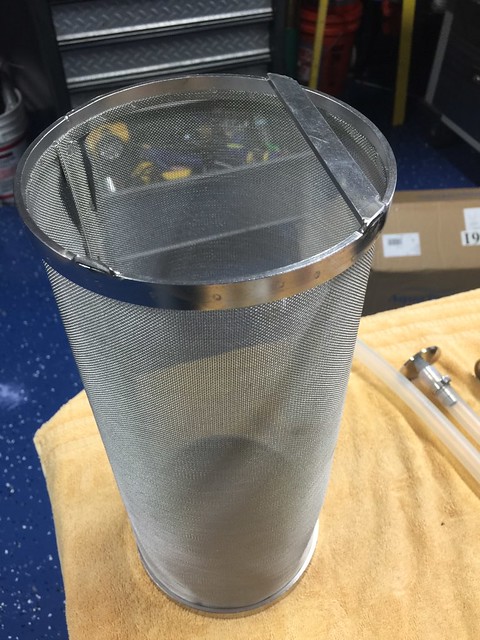

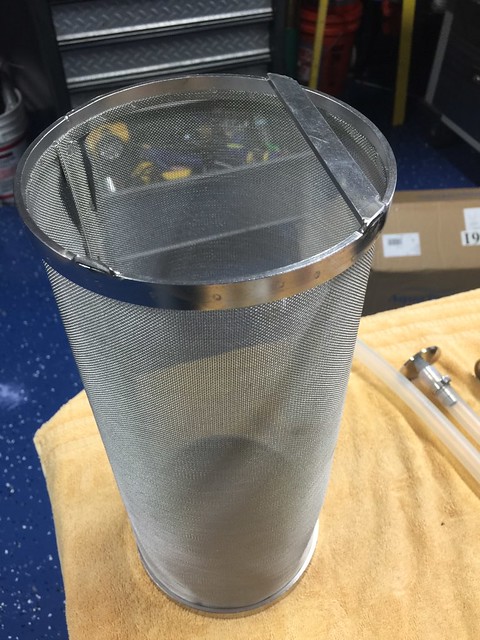

I want to first give credit to Brundog. This is his design and its awesome. I decided to go with a 1.5” tri clamp version of his design. I had to source my parts from different vendors. Spray nozzle, nipple, and reducer from McMaster Carr. 1.5” instrument T from Brewers Hardware. ½” female/female and and 5/8 barb tri adapter from Brew Hardware. 1.5” weldless bulkhead and 42mm drill bit from SS Brewtech. I ordered the 2.5" nipple but 1.5” setup requires a 1.5 inch nipple so I had to substitute a brass one from home depot. Here is a picture of my parts.

Here are the internal parts.

The hole was drilled and then I de burred it using a round file.

I then installed the bulkhead.

Here is a video of the nozzle in action.

Here is a rolling boil. I initially added weight to the lid but it was not needed. You can see no steam was escaping.

Here are the internal parts.

The hole was drilled and then I de burred it using a round file.

I then installed the bulkhead.

Here is a video of the nozzle in action.

Here is a rolling boil. I initially added weight to the lid but it was not needed. You can see no steam was escaping.

Last edited:

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

The nozzle looks awesome. I’m really interested in how your brew day goes. Without an exhaust fan wonder if your whole house will smell like a brewery?

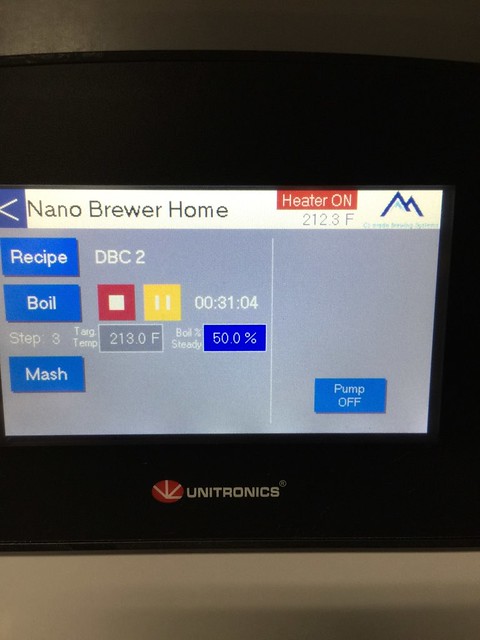

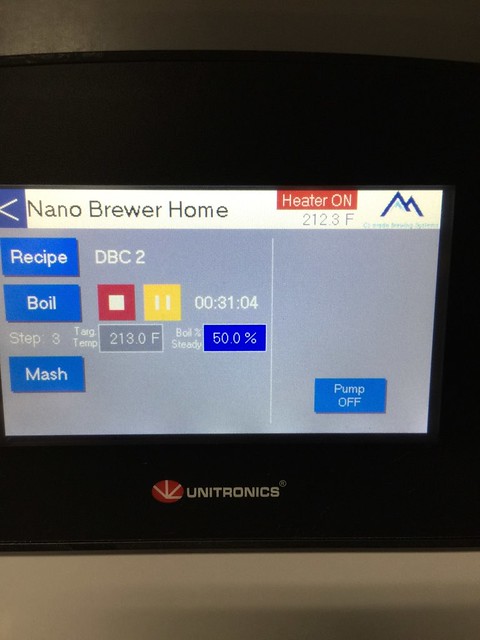

This was my first time brewing with the Colorado System. Other than some self inflicted wounds, it went well. I used all RO water (14.5 gal) and built my profile. Beer Smith indicated I would need 27ml of lactic acid to hit 5.3 PH. I initially added 15ml and after 10 minutes of mashing my PH was 4.4. To get the PH up I added a little baking soda in RO water. It took about 1.5 teaspoons to get it to 5.3. I did a 90 minute mash to make up for the time I was lolly gagging at 4.4 PH. The SS Brewtech manifold worked great. I stirred once during the mash and ran the whirlpool wide open 90% of the time (19lb grain bill with 8oz rice hulls). I held back a gallon of water to sparge at the end to increase efficiency. I put an induction hot plate with a 2 gallon kettle on the upper self to hold the sparge water. The boil went well and the condenser was flawless. Zero steam left the pot. If you routed the waste water directly into a drain you would eliminate most of the smell. My boil off rate was again .7 gph and it produced about 13 gallons of waste water. The disappointment was my wort filter. With ten minutes left I wanted to whirlpool to sanitize the filter and plate chiller. After about 9 minutes the filter was totally clogged (2 oz of pellet hops). I had to make some plumbing adjustments to chill the wort. It is now sitting in the fermenter at 62 degrees.

Mash in

Clogged wort filter

Some observations......

I love the CBS system. The software needs a few tweeks but jumping into a manual PID is easy. Overall very satisfied with results, quality, and the customer service.

I need to figure out the wort filter. Maybe a hop basket and use the wort filter as a secondary to protect the chiller. I will need a special mod on a hop basket to keep the lid sealed for the condenser system.

The SS unitank is awesome

Brundog's condenser mod in a no brainer. I like the DIY version better than Brew Boss's. Its larger, cheaper, and looks better. No lid gasket needed.

Last edited:

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

I also use a hop basket so I'd be interested in seeing what you come up with to seal around it.

I ordered a hop basket from Brew Hardware (https://www.brewhardware.com/product_p/hopbasket800.htm) I also ordered two super magnet strips (https://www.amazon.com/gp/product/B01L2VN4VC/?tag=skimlinks_replacement-20) My plan is to JB weld one to the basket and use the other one on the outside of the kettle to hold the basket in place. This will keep the lid sealed for the condenser system.

Last edited by a moderator:

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

I ordered a hop basket from Brew Hardware (https://www.brewhardware.com/product_p/hopbasket800.htm) I also ordered two super magnet strips (https://www.amazon.com/gp/product/B01L2VN4VC/?tag=skimlinks_replacement-20) My plan is to JB weld one to the basket and use the other one on the outside of the kettle to hold the basket in place. This will keep the lid sealed for the condenser system.

Interesting idea! I thought of just notching the kettle lid just enough to accommodate the hop basket arm but afraid it would provide too much leakage for the eductor to work properly.

Last edited by a moderator:

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

Anyone with the Nano 20.........Do you think I could do a 10 gallon batch of stout with a 32 lb grain bill and a 17 gallon water vol? I would hold back 2 gallons for a sparge at the end.

02RedWS6TA

Well-Known Member

Mash will probably be sticky but I don't see any issues with it. I ran 32-34# in my 20 all the time. My RIS was close to what you're aiming for. It was a sticky mash but really not bad at all.

02RedWS6TA

Well-Known Member

For hop spiders arbor and Duda diesel will both make custom ones. You can just ask them to make one with some feet on it to keep it off the bottom of the kettle. Should work well, pretty cool mod for the steam. I saw the brew boss one a couple weeks ago, great job on the diy.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

If you're using an element in the kettle, just place the basket on the bottom to the side of the element. No hooks or magnets needed.

I have a hop spider, pellet hops get clogged in it too; they are meant for leaf, Ive also go a stainless hop filter and it clogs with pellet hops big time, I removed mine and don't filter any more, I whirlpool to the center and drain strait into the fermenter and only a small amount of hops enter the fermenter, its fine

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

Here is my hop basket mod. I ordered the 500 micron from Bobby at Brew Hardware. He has 300, 500, and 800 micron.

I attached a 33lb super magnet to the basket with JB Weld.

I then used a Dremel tool to cut off the hangars on the basket.

Here it is installed in the kettle allowing the lid to seal completely. It is rock solid and actually a little difficult to remove. The magnets are incredible. I may add a little felt to the outside magnet to make removing it easier. Infinite height adjustment too!

I attached a 33lb super magnet to the basket with JB Weld.

I then used a Dremel tool to cut off the hangars on the basket.

Here it is installed in the kettle allowing the lid to seal completely. It is rock solid and actually a little difficult to remove. The magnets are incredible. I may add a little felt to the outside magnet to make removing it easier. Infinite height adjustment too!

Last edited:

That looks great. I have thought about doing something like that, but always wondered if keeping your hops cooped up in a cage might interfere with extraction. Someone tell me that I am worrying about nothing, because it would sure make cleaning easier if the hop gunk was not in the bottom of the giant kettle...

BudgetBrewer

Well-Known Member

- Joined

- Sep 20, 2015

- Messages

- 156

- Reaction score

- 42

I still just use a hop sock... Cloth bag on a pvc pipe hanger. can reuse them several times, cheap and easy to use. I used to use one of those stainless mesh hop filters over the pickup tube.... It would completely clog with minimal hop additions making recirculating and chilling / whirlpooling impossible. That does look slick tho. good job.

jabba11

www.CeeGeeBrewing.com

Real quick I thought Id post this idea. I am gonna kettle sour a batch this week. I was considering ways to seal the lid as much as possible and came up with this which is just some silicon tubing sliced and cut to length. I plan to drill a hole in my lid for a stopper then feed co2 into the kettle through the valve on the bottom. I think this will work fine. I am gonna place a 5 pound weight on the lid to keep a little pressure on it.

Attachments

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

You're going to go through a lot of CO2 if you're planning on it being a constant thing.

Why not just float some plastic food wrap on the surface as a barrier?

Why not just float some plastic food wrap on the surface as a barrier?

Similar threads

- Replies

- 11

- Views

- 698

Colorado

Nano Homebrew System (10-15 Gallons)

- Replies

- 0

- Views

- 712