Please do! I want a club of on-demand fly spargers!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Two vessel HERMS system idea

- Thread starter corneyl

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

That was the idea. I figured it should work as long as I didn't mix up the mash after putting in the sparge water. The wort has sugars in it, so it's higher density and should stay below the sparge water and basically act like a fly sparge. You do need a fairly big mash tun to hold it all. I have a 10 gallon cooler - it had 11.5 lbs of grain + about 7 gallons of water in total. Filled up almost full. Batch size was 5 gallons.

Next is to try and duplicate your on demand sparge heating but I have to upsize the RIMS heater first. It's too small for that right now.

My mash tun is only 7.5 gallons. I've been recirculating from the mash tun into the boil kettle and back with full boil volume. Any explanation why I can only get 62% while you get 80+? I doubt I can hold all the water in that mash tun as I like a little higher gravity.

My mash tun is only 7.5 gallons. I've been recirculating from the mash tun into the boil kettle and back with full boil volume. Any explanation why I can only get 62% while you get 80+? I doubt I can hold all the water in that mash tun as I like a little higher gravity.

For one thing, you are doing a no-sparge process, whereas @Wizard_of_Frobozz is sparging. That alone is good for a 9 percentage point difference in lauter efficiency (see the chart in post #2 in this thread.) Also, are you leaving significant liquid volume in the bottom of your MLT? That will reduce you lauter efficiency below what is shown in the referenced chart.

Remember that your mash efficiency is your conversion efficiency times your lauter efficiency. It's quite possible that your conversion efficiency is low (it should be 95% or better.) You need to measure your conversion efficiency using the method here to know where you stand.

Things you can to do to improve conversion efficiency:

- Crush as fine as you can without getting a stuck mash

- Mash for longer time

- Control mash pH (if you don't already)

Finally, are you talking mash efficiency or brewhouse efficiency? Brewhouse efficiency equals mash efficiency times fermenter volume divided by post-boil volume. The more wort/trub you leave in your BK the bigger the difference between your mash efficiency and your brewhouse efficiency. Comparing your brewhouse efficiency to someone else's mash efficiency can make things look worse than they actually are (I don't know if Wizard is stating mash or brewhouse.)

Brew on

Finally, are you talking mash efficiency or brewhouse efficiency? Brewhouse efficiency equals mash efficiency times fermenter volume divided by post-boil volume. The more wort/trub you leave in your BK the bigger the difference between your mash efficiency and your brewhouse efficiency. Comparing your brewhouse efficiency to someone else's mash efficiency can make things look worse than they actually are (I don't know if Wizard is stating mash or brewhouse.)

Brew on

Im talking brewhouse. I dump everything in from my boil kettle to the fermenter. I account for loss in my mash tun but I do the best I can draining it.

I may keep my rims the same and just add a hlt.i have a five gallon cooler, I would just have to put a ball valve on it. Then I could at least fly sparge. Would there be enough liquid to recirculate? I don't know yet, but it's worth a shot.

Another thought... could I mash for say 30 minutes and heat a batch sparge to my target temp then recirculate the whole thing? I could still raise the temp to mash out towards the end. Still be two vessel and not have to worry about hoses so much.

If you mash with say 4.5 gal strike water, and then add and mix (recirculate) 3.5 gal of additional water, the lauter efficiency will be the same as if you mashed with 8.0 gal of strike water initially. Sparging involves rinsing residual sugar out of the grains with fresh water. To do something like a fly sparge, you need an HLT separate from the BK, or an MLT capable of holding the total mash volume plus sparge volume. In the second case the sparge water would get added (potentially from the BK) on top of the mash with care taken to minimize the mixing. Then when you run-off, the concentrated wort drains first, and then the fresh water that was on top of the mash washes thru the grain bed. Since the top water has very low sugar concentration, it picks up residual sugar from the grain, much like a traditional fly sparge. This is what @Wizard_of_Frobozz described a few posts above.Im talking brewhouse. I dump everything in from my boil kettle to the fermenter. I account for loss in my mash tun but I do the best I can draining it.

I may keep my rims the same and just add a hlt.i have a five gallon cooler, I would just have to put a ball valve on it. Then I could at least fly sparge. Would there be enough liquid to recirculate? I don't know yet, but it's worth a shot.

Another thought... could I mash for say 30 minutes and heat a batch sparge to my target temp then recirculate the whole thing? I could still raise the temp to mash out towards the end. Still be two vessel and not have to worry about hoses so much.

Brew on

Wizard_of_Frobozz

Well-Known Member

Please do! I want a club of on-demand fly spargers!!

It will be a while - have to make some control panel changes before I can upsize the RIMS heater and I've got a new brew room to build first...

My mash tun is only 7.5 gallons. I've been recirculating from the mash tun into the boil kettle and back with full boil volume. Any explanation why I can only get 62% while you get 80+? I doubt I can hold all the water in that mash tun as I like a little higher gravity.

For one thing, you are doing a no-sparge process, whereas @Wizard_of_Frobozz is sparging. That alone is good for a 9 percentage point difference in lauter efficiency (see the chart in post #2 in this thread.) Also, are you leaving significant liquid volume in the bottom of your MLT? That will reduce you lauter efficiency below what is shown in the referenced chart.

Remember that your mash efficiency is your conversion efficiency times your lauter efficiency. It's quite possible that your conversion efficiency is low (it should be 95% or better.) You need to measure your conversion efficiency using the method here to know where you stand.

Things you can to do to improve conversion efficiency:

- Crush as fine as you can without getting a stuck mash

- Mash for longer time

- Control mash pH (if you don't already)

Finally, are you talking mash efficiency or brewhouse efficiency? Brewhouse efficiency equals mash efficiency times fermenter volume divided by post-boil volume. The more wort/trub you leave in your BK the bigger the difference between your mash efficiency and your brewhouse efficiency. Comparing your brewhouse efficiency to someone else's mash efficiency can make things look worse than they actually are (I don't know if Wizard is stating mash or brewhouse.)

Brew on

I was talking mash efficiency, since the experiment was in mash technique. I should have stated that - sorry!

A lot of variables can affect things, like doug293cz said. Losses post-mash can be affected by amount of hops, length of hoses, size of kettle, use of secondary fermenter, etc.

My brewhouse efficiency is typically around 75%. Hard to pin down why you see different results without knowing the details.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

rshortt

Well-Known Member

Hi everyone,

How's all your 2 vessel HERMS systems going?

I've been planning on going this route for a couple of years now. Up until now I'm indoor electric 19 gallon BIAB.

I finally ordered a nice 50' 1/2" stainless coil for my next BK/HLT that will be 25 or 30 gallons depending on what deal I can find. At first I think I'll just use my existing BK as a MT with a custom made false bottom. Right now I'll make due with one pump (march center inlet) but envision eventually using two.

I like what I'm reading in this thread and I think a system like this has a lot of potential and many combinations of mash volume, thickness, no/sparging.

Have you guys seen these videos? A source of inspiration, for sure.

[ame]https://www.youtube.com/watch?v=28kYMdQsqjQ[/ame]

[ame]https://www.youtube.com/watch?v=xqO8r5TocIc[/ame]

Cheers!

How's all your 2 vessel HERMS systems going?

I've been planning on going this route for a couple of years now. Up until now I'm indoor electric 19 gallon BIAB.

I finally ordered a nice 50' 1/2" stainless coil for my next BK/HLT that will be 25 or 30 gallons depending on what deal I can find. At first I think I'll just use my existing BK as a MT with a custom made false bottom. Right now I'll make due with one pump (march center inlet) but envision eventually using two.

I like what I'm reading in this thread and I think a system like this has a lot of potential and many combinations of mash volume, thickness, no/sparging.

Have you guys seen these videos? A source of inspiration, for sure.

[ame]https://www.youtube.com/watch?v=28kYMdQsqjQ[/ame]

[ame]https://www.youtube.com/watch?v=xqO8r5TocIc[/ame]

Cheers!

Wizard_of_Frobozz

Well-Known Member

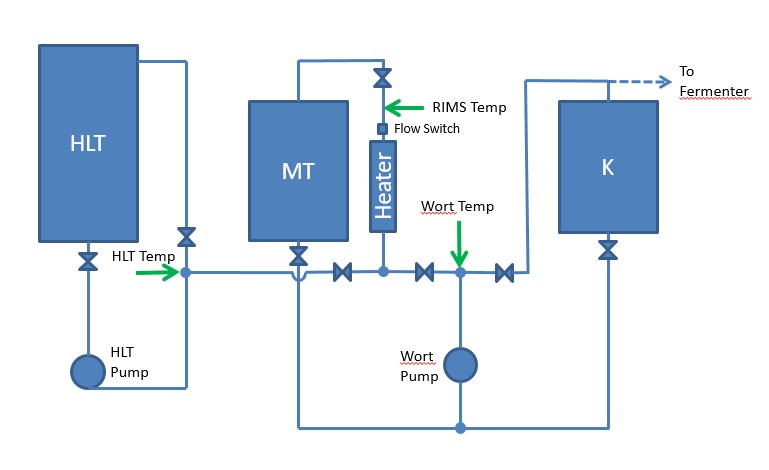

I've been doing a 2 vessel brew session for a while now, although my system is still built as a 3 vessel (I'm just not using the HLT anymore!). A full redesign is underway, but the new brew room construction comes first.

My setup is similar to what he was doing in the videos, with some exceptions:

My biggest limitation is the size of the mash tun. I brew in 5 gallon batches, and the 10 gallon mash tun can only fit about 15 lbs of grain plus all the water required to get about 6.25 gallons in the kettle (pre-boiling). At my efficiency, that limits me to about 1.080 for original gravity. That's fine with me, as I'm not a "big" beer drinker, but it is a limitation worth pointing out.

I'd also like to point out that the HERMS coils in the boil kettle looks like it would be a PITA to clean. You might be able to have it do double duty and be an immersion chiller, but the prospect of cleaning that coil doesn't appeal to me. I like RIMS over HERMS anyway because it's direct temperature control of the mash; never had any scorching issues.

My setup is similar to what he was doing in the videos, with some exceptions:

- I use a RIMS heater vs. HERMS coil in the boil kettle

- My mash tun is a 10 gallon Rubbermaid cooler

- I don't recirculate the mash after the entire sparge water volume has been added to the mash tun

My biggest limitation is the size of the mash tun. I brew in 5 gallon batches, and the 10 gallon mash tun can only fit about 15 lbs of grain plus all the water required to get about 6.25 gallons in the kettle (pre-boiling). At my efficiency, that limits me to about 1.080 for original gravity. That's fine with me, as I'm not a "big" beer drinker, but it is a limitation worth pointing out.

I'd also like to point out that the HERMS coils in the boil kettle looks like it would be a PITA to clean. You might be able to have it do double duty and be an immersion chiller, but the prospect of cleaning that coil doesn't appeal to me. I like RIMS over HERMS anyway because it's direct temperature control of the mash; never had any scorching issues.

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

I have a question about your BK. You said that you use a RIMS heater on the BK to heat the mashtun. Do you also use another heat source in your BK for boiling? Electrice? Gas?

Wizard_of_Frobozz

Well-Known Member

I have a question about your BK. You said that you use a RIMS heater on the BK to heat the mashtun. Do you also use another heat source in your BK for boiling? Electrice? Gas?

No, the BK has it's own heating element in it (4500W element). The RIMS tube is separate with a 2500W element (which I limit to 50% duty cycle, as I don't really need that much power on the RIMS). RIMS tube is only used for the mash. Sorry about the confusion - I was trying to state that I have a RIMS vs. HERMS system.

During the mash, I'm recirculating the mash through the RIMS tube while the boil kettle is heating up the sparge water. I then transfer the entire sparge volume to the top of the mash tun, then pump the mash tun over to the boil kettle. Max. current with both heaters at the same time is just under 30 amps. My next upgrade is going to go to 50 amp service, which will make it much more flexible with regards to heater sizing.

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

Is your RIMS 240v?

Wizard_of_Frobozz

Well-Known Member

Is your RIMS 240v?

Yes, couldn't do it under 30 amps unless both heaters were 240V. My new brew room is going to have 50 amp service...

I could rewire the RIMS heater to be 120V and really cut down on it's power, as I don't really need the full 2500W, but I just use the BCS to limit the duty cycle instead. That way, I can use the full power of the RIMS while pre-heating the water in the mash tun prior to strike.

I've found that during mash re-circulation, the flow rate is slow enough (limited by the grain bed) that I get localized boiling in the RIMS tube if I have the duty cycle above 50%. At that level, I still maintain mash temps fine; ramps up in temperature are kind of slow, but within tolerable levels.

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

What do you use to recirculate into the mashtun? A sparge ring, auto sparge, hose, etc?

Btw you have any links or pics of your build. As you may have guessed I am very curious about it.

Btw you have any links or pics of your build. As you may have guessed I am very curious about it.

Wizard_of_Frobozz

Well-Known Member

What do you use to recirculate into the mashtun? A sparge ring, auto sparge, hose, etc?

Btw you have any links or pics of your build. As you may have guessed I am very curious about it.

I drilled a hole into the side of the cooler at the top; I built a CPVC manifold that I just press fit together inside the mash tun and then run a pipe with a connector through the hole. Drilled holes in the CPVC pipes to sprinkle the water at the top of the tun. It's very ghetto, but it works. In my next big upgrade, I'll likely go to a locline setup like Bobby sells:

https://www.brewhardware.com/product_p/mashrecirculation.htm

https://www.brewhardware.com/product_p/mashspargering.htm

Here are a couple of pictures and schematic; again, it's currently a 3 vessel system that I just don't use the HLT anymore, so you can ignore the big insulated tank on the left. No problem with being curious; ask @Brundog and @Augiedoggy how many times I've asked them for details on their setups!

Wizard_of_Frobozz

Well-Known Member

Here are some pictures of the sparge/mash recirc return manifold. Sorry about the orientation; no idea how to rotate pictures...

rabeb25

HE of who can not be spoken of.

Hi everyone,

How's all your 2 vessel HERMS systems going?

I've been planning on going this route for a couple of years now. Up until now I'm indoor electric 19 gallon BIAB.

I finally ordered a nice 50' 1/2" stainless coil for my next BK/HLT that will be 25 or 30 gallons depending on what deal I can find. At first I think I'll just use my existing BK as a MT with a custom made false bottom. Right now I'll make due with one pump (march center inlet) but envision eventually using two.

I like what I'm reading in this thread and I think a system like this has a lot of potential and many combinations of mash volume, thickness, no/sparging.

Have you guys seen these videos? A source of inspiration, for sure.

https://www.youtube.com/watch?v=28kYMdQsqjQ

https://www.youtube.com/watch?v=xqO8r5TocIc

Cheers!

Hey! Thats ME.

rshortt

Well-Known Member

Hey! Thats ME.

That's awesome! I have so many questions considering I'm building a similar system, but not automated.

The first one is, are you still brewing on that? I'm gonna check out your sig links before I ask more...

rabeb25

HE of who can not be spoken of.

That's awesome! I have so many questions considering I'm building a similar system, but not automated.

The first one is, are you still brewing on that? I'm gonna check out your sig links before I ask more...

No I am not, I have built another system. Ask away.

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

What did you build?

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

As far as I understood the process, with these 8 steps it should be possible to brew a beer. In step 5 I add the sparge water while the mash water (is that the correct term?) is still in the pot. So sparging probably works out a bit less effective, but still better than no sparging at all.

In total I would need two vessels, a heat exchange, two pumps and 8 valves.

Do you guys think that this would work out ok? Has anyone (used) a 2V-HERMS?

Pictured below is my system with 6 valves, 2 pumps, 2 Heat exchangers, 1 heating element. I will eventually add a 7th valve on the water source for redundancy since mine will be connected to the house water supply.

https://www.homebrewtalk.com/showthread.php?t=633943

My steps are similar to yours and outlined in the link above. Planning to run the first batch through this in November.

.

4of7

60sqftbrewhouse

- Joined

- Apr 16, 2017

- Messages

- 549

- Reaction score

- 111

Most HERMS systems use a 3-vessel system, but I was wondering whether it's also possible to do it with 2 vessels. I couln't find a lot of info on this. But one needs less valves, just two vessels, but a separate heat exchanger, so it could be more cost effective. A disadvantage is that sparging is harder to do, see the attachment for my idea.

As far as I understood the process, with these 8 steps it should be possible to brew a beer. In step 5 I add the sparge water while the mash water (is that the correct term?) is still in the pot. So sparging probably works out a bit less effective, but still better than no sparging at all.

In total I would need two vessels, a heat exchange, two pumps and 8 valves.

Do you guys think that this would work out ok? Has anyone (used) a 2V-HERMS?

BTW: please correct me if I'm using wrong terms, beginner here

View attachment 393727

2v ebiab, 15 gallon kettle, 10 gallon batches,50l kegmenter,, not herms, 3.5-4 hr brew days...

2v ebiab, 15 gallon kettle, 10 gallon batches,50l kegmenter,, not herms, 3.5-4 hr brew days...LazyPasta

Active Member

@Wizard_of_Frobozz , I'm currently about to pull the trigger on a 2-vessel build and it sounds like I'm on the same page as you with how I want my system to work (@BrunDog helped persuade me this way too!). I would like to do both 5 and 10 gallon batches. I will use a 15 gallon kettle and and am considering a 20 gallon mash tun. To recirculate the mash, I will use a RIMS Rocket. I am planning on having a 50 amp controller that I can then heat my sparge water in my kettle as the mash finishes up. I will gently transfer the heated sparge water on top of the mash grains and then drain back to the kettle. I think I will need the 20 gallon mash tun so that I can hopefully get to around a 1.08 OG. Otherwise I may need to add as much heated sparge water as I can to the Mash tun, and then after transferring back to the kettle, cold sparge the remainder of the sparge volume (a gallon or two from a separate container). Most of my beers are well below the 1.08 level, so I shouldn't have to worry about that often. I am planning on using High Gravity's Worthog EBC-350 controller so that I can operate the boil coil in the kettle and the Rims Rocket at the same time.

You got my attention when you mentioned you get boiling in your RIMS tube during the mash recirculation. I'm no expert on building controllers, which is why I was going to buy the Worthog in the first place. Can you explain the duty cycle to me? I was under the impression that my controller would turn the RIMS Rocket on and off as required depending on what it was sensing at the output? I'm going to be using a 240V RIMS Rocket, so now you have me thinking. I don't want some sort of disaster in my RIMS element!

Thanks in advance!

You got my attention when you mentioned you get boiling in your RIMS tube during the mash recirculation. I'm no expert on building controllers, which is why I was going to buy the Worthog in the first place. Can you explain the duty cycle to me? I was under the impression that my controller would turn the RIMS Rocket on and off as required depending on what it was sensing at the output? I'm going to be using a 240V RIMS Rocket, so now you have me thinking. I don't want some sort of disaster in my RIMS element!

Thanks in advance!

Wizard_of_Frobozz

Well-Known Member

Glad I could help inspire your build! I completely agree on going bigger on the mash tun - that is the single biggest limitation of my setup, and I'm considering getting a bigger mash tun myself. Don't forget just how big, heavy, and hard to clean a 20 gallon stainless steel mash tun can be...I'm seriously looking at Pancho's Keg Cooler instead of a kettle. Lot less expensive and a lot lighter...not as shiny however!

As far as the RIMS tube and duty cycle go, here's my brief explanation for what's going on:

In my case, since my original RIMS tube & 3500W heating element are short (about 9 inches), I couldn't do a whole lot about increasing the fluid flow rate inside the tube without completely changing the RIMS tube and heating element. I am in the process of doing exactly that, but while waiting for THAT upgrade to get funded, I chose the other option: Reduce the power of the heating element.

Duty cycle is simply the maximum amount of time that the heater is allowed to be "on". I've set my BCS controller to limit the "on" time to be 50%, so even if the controller tries to turn it on more than 50% of the time, the duty cycle limit will prevent it from doing so. It works, but it's a short term fix until I fix the overall design limitation of the short, high power heating element.

My new design will be this heating element run at 120V (about 2000W power over 22") set inside an 1-1/4" stainless steel pipe. This keeps the overall space between the pipe wall and heating element to a minimum, which will keep the flow velocity inside the tube higher, the overall power less, but more contact time due to the longer heating element and tube.

I would be really concerned about using a RIMS rocket, mainly because it's short and fat. This means less contact between the fluid and the heating element, lower flow velocity through the RIMS chamber, and WAY more power than you actually need to heat the mash. Now, if you are going to do the on-demand sparge water heating like @BrunDog, you do need that power for sparge water heating, and can limit the power (duty cycle) during the mash. It all depends on what you want your system to be able to do. I like the simplicity of just putting the sparge water right on top of the mash.

Hope that helps!

As far as the RIMS tube and duty cycle go, here's my brief explanation for what's going on:

- The heating element puts heat into the fluid as it flows past the element through the RIMS tube

- The slower the fluid flow, the more heat put into the fluid that is in direct contact with the surface of the heating element over a set period of time

- If the temperature of the fluid in contact with the heating element goes above 212F, it boils

- The boiling causes all kinds of issues (pulsing of the flow, scorching, uneven heating, etc)

- Reduce the power of the heating element

- Increase the flow velocity inside the RIMS tube

In my case, since my original RIMS tube & 3500W heating element are short (about 9 inches), I couldn't do a whole lot about increasing the fluid flow rate inside the tube without completely changing the RIMS tube and heating element. I am in the process of doing exactly that, but while waiting for THAT upgrade to get funded, I chose the other option: Reduce the power of the heating element.

Duty cycle is simply the maximum amount of time that the heater is allowed to be "on". I've set my BCS controller to limit the "on" time to be 50%, so even if the controller tries to turn it on more than 50% of the time, the duty cycle limit will prevent it from doing so. It works, but it's a short term fix until I fix the overall design limitation of the short, high power heating element.

My new design will be this heating element run at 120V (about 2000W power over 22") set inside an 1-1/4" stainless steel pipe. This keeps the overall space between the pipe wall and heating element to a minimum, which will keep the flow velocity inside the tube higher, the overall power less, but more contact time due to the longer heating element and tube.

I would be really concerned about using a RIMS rocket, mainly because it's short and fat. This means less contact between the fluid and the heating element, lower flow velocity through the RIMS chamber, and WAY more power than you actually need to heat the mash. Now, if you are going to do the on-demand sparge water heating like @BrunDog, you do need that power for sparge water heating, and can limit the power (duty cycle) during the mash. It all depends on what you want your system to be able to do. I like the simplicity of just putting the sparge water right on top of the mash.

Hope that helps!

LazyPasta

Active Member

Awesome post, @Wizard_of_Frobozz ! So is the duty cycle what the SSR acomplishes with your PID? So if you had an EZboil from Auber, it seems like you would be able to mess with this power reduction? I guess the PID that you use with your mash recirculation would be set with a duty cycle, and then the boil PID would just be set full blast. Or if you have a nicely sized RIMS tube that keeps your wort velocity in a good range, you don't have to worry at all.

That seems like a valid concern with the RIMS Rocket. I've heard some people on these forums having some issues with the RIMS rocket, but I'm too much of a novice with the electric setups to know if it's the same issues as a RIMS tube. I definitely like the cost of putting together a RIMS tube vs the cost of a RIMS Rocket.

Since you're using a kettle element and a mash recirculation element, did you make the move to 50 amp? If so, what controller are you using/did you build a controller?

That seems like a valid concern with the RIMS Rocket. I've heard some people on these forums having some issues with the RIMS rocket, but I'm too much of a novice with the electric setups to know if it's the same issues as a RIMS tube. I definitely like the cost of putting together a RIMS tube vs the cost of a RIMS Rocket.

Since you're using a kettle element and a mash recirculation element, did you make the move to 50 amp? If so, what controller are you using/did you build a controller?

I wouldn’t fear RIMs. Use a 1.5” tube and a 4500 or 5500 W (@240 VAC) straight element run at 120V and you will be fine! Just make sure you are getting adequate flow - you’ll know when the controller‘s power output is oscillating or not steady. 2 GPM and higher should be fine!

We made a unique RIMs element for high power scenarios. By no means do you need it but it proves that proper design is everything in RIMs performance (good flow, turbulent flow, really low heat density, minimal dead space, vertical orientation, etc.).

We made a unique RIMs element for high power scenarios. By no means do you need it but it proves that proper design is everything in RIMs performance (good flow, turbulent flow, really low heat density, minimal dead space, vertical orientation, etc.).

LazyPasta

Active Member

Hi @BrunDog , I'm definitely not fearing RIMS. I know the 2-vessel with dual RIMS elements will give me the speedy brew day I'm looking for! Is there a reason you would run the 240V element at 120V other than reducing the watts/area? I guess if you're using 240V, the RIMS tube could get pretty long to get to ULWD and prevent the scorching. Does your controller just have two different outlets then (240 outlet for your boil element and 120 for your RIMS tube)?

Wizard_of_Frobozz

Well-Known Member

Awesome post, @Wizard_of_Frobozz ! So is the duty cycle what the SSR acomplishes with your PID? So if you had an EZboil from Auber, it seems like you would be able to mess with this power reduction? I guess the PID that you use with your mash recirculation would be set with a duty cycle, and then the boil PID would just be set full blast. Or if you have a nicely sized RIMS tube that keeps your wort velocity in a good range, you don't have to worry at all.

That seems like a valid concern with the RIMS Rocket. I've heard some people on these forums having some issues with the RIMS rocket, but I'm too much of a novice with the electric setups to know if it's the same issues as a RIMS tube. I definitely like the cost of putting together a RIMS tube vs the cost of a RIMS Rocket.

Since you're using a kettle element and a mash recirculation element, did you make the move to 50 amp? If so, what controller are you using/did you build a controller?

Duty Cycle and PID are two different control methods, really. No matter what you use, the SSR just turns off and on - there is no "50%" setting on the SSR itself. To get 50% power, the controller turns the SSR "on" half the time, and "off" half the time, which averages out to 50% power. The time interval used is typically under 1 second, and is set by the user in the controller. Since this time interval is so short, the heating element won't heat up too much during the "on" period, because it doesn't have enough time to do so. This is why you use a Solid State Relay for heater control - no moving parts. If you tried to open and close a mechanical relay that rapidly, it would fail pretty quickly.

Now, for PID control, the controller determines how much "on" time it needs in order to achieve the temperature setpoint. It uses a complicated formula using three main parameters: Proportional (P), Integral (I), and Derivative (D). This is a fancy way of saying the PID controller takes into account how far away you are from setpoint, and how fast the temperature is changing to try to hit the setpoint with minimal overshoot. After calculating how much power is needed, it turns the SSR "on" and "off" to match the % power it calculated. It's constantly doing this calculation, and adjusting the "on" time of the SSR. PID control is typically used during mash recirc or step mashes to minimize overshooting your desired rest temperature.

For duty cycle control (also known as manual control on some controllers), you just tell the controller what power % you want, and it turns the SSR "on" and "off" to match the % you told it. This is typically used for the boil, where you want to establish a consistent boil off rate.

I currently use a BCS-460. It allows me to set a duty cycle limit during PID control, so even if the PID decides it wants 75% power, the duty cycle limit of 50% overrides it, and won't allow it to go beyond that. It prevents the localized boiling that occurs due to the short, high power RIMS, but it also limits how fast I can step mash.

I'm currently in the process of building a new brew room that has a 50 amp circuit in it. Once that's done, and funds become available again (darn those kids for wanting to go to college!), I will be rebuilding my RIMS tube as I described a few posts ago, and switching my controller over to an Arduino with BruControl. My main issue with the BCS-460 is that it is very limited in I/0. Only 4 temperature probes for that model; BruControl offers a whole lot more flexibility for less money than it would be to upgrade to the BCS-482. Plus, @BrunDog is very active at supporting his product and adding features his customers have asked for.

Last edited:

Sounds a lot like the High Gravity System. Brewing System │ Electric │ Wort Hog 10 gallon 2-Vessel

Cioffi

Well-Known Member

I am going to bite my tongue (thumbs, actually) and avoid what I would love to be a philosophical discussion. This has nothing to do with you corneyl... you just lit my fire with the 2-vessel thing which has been on my mind.

So let's help you out... I think 2 vessels is the way to go. All the benefits of multi vessel without a wasted on (the HLT). I think your idea is sound, and as you noted sparging is the only hiccup. The problem you have fundamentally is no third place for water or wort. So you have to make a choice during the sparge:

1. Drain you initial runnings into a bucket.

2. Drain your runnings in into the BK, along with the remaining sparge water.

3. Put all your sparge water into the MLT and drain into the BK.

4. Batch sparge once.

Given these choices, I would NOT do #2 or #4. As Doug said 2 is like a full volume mash. I don't agree it is the same, but you won't get the best efficiency doing this because of course, you are pumping extracted sugars back on to the mash surface. 4 is just plain silly to me. #1 is more manual than I like but you could do a normal fly sparge.

But i see no downside to #3 other than some lost efficiency. Put your entire sparge volume on top of the grain bed without mixing, then drain into your BK until you hit your pre-boil volume. I think that will work well.

Although an old thread, I'm curious as to why you think RIMS is better than HERMS. I've been using HERMS for a while, but am now in the process of rebuilding the rig. I have the harware for a RIMS. Thoughts?

Similar threads

- Locked

Withdrawn

15gal 3 vessel Electric HERMS $1800

- Replies

- 11

- Views

- 2K

- Replies

- 9

- Views

- 1K

- Replies

- 8

- Views

- 508

Latest posts

-

-

-

-

-

The Dysfunctional-Palooza Obnoxious Masshole BS Thread

- Latest: Hoppy2bmerry

-

-

-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)