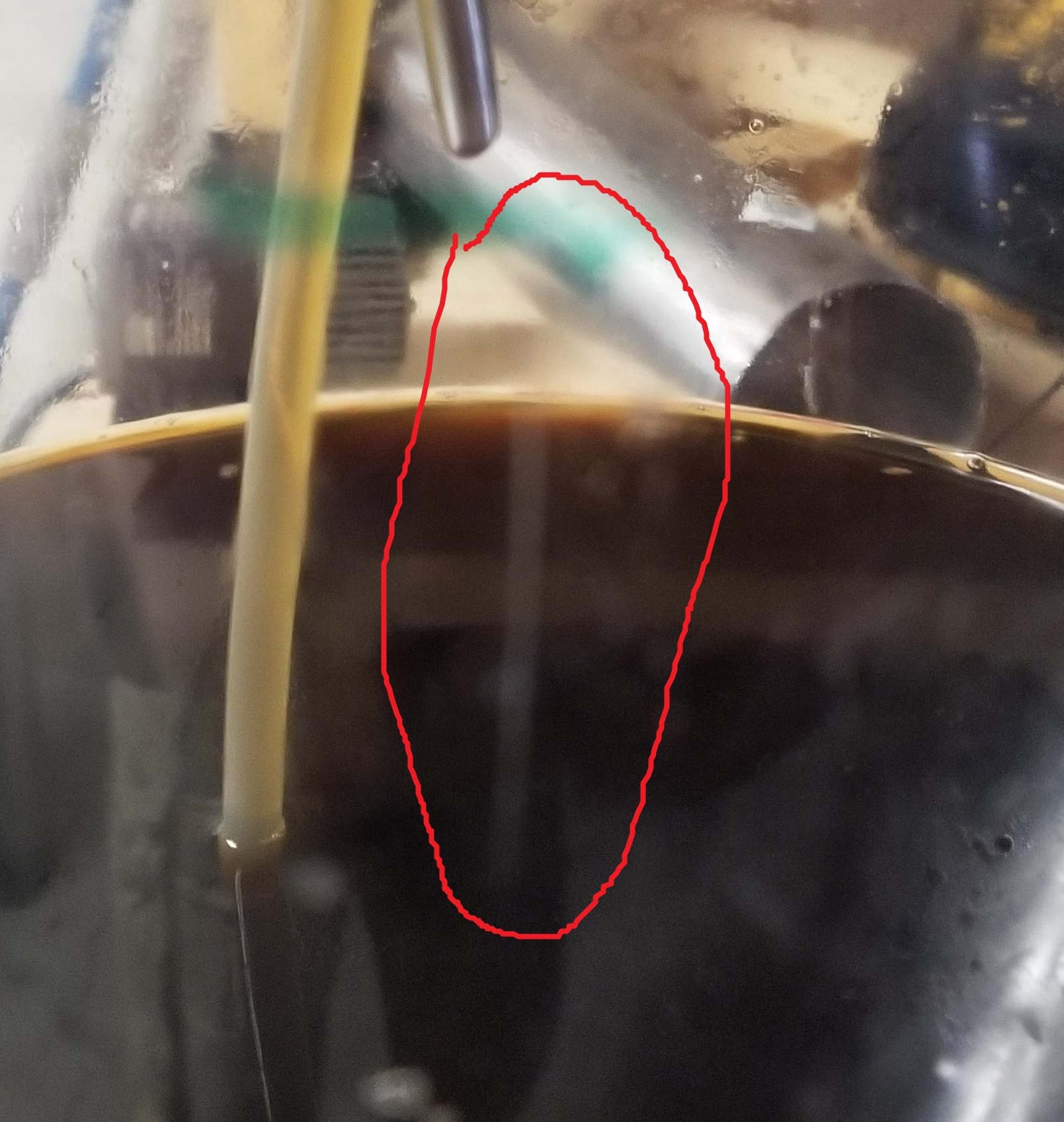

Don't see that it's been mentioned here, but there's another method for adding dry hops; and no opening of the lid is necessary. Buy some sous vide magnets (Amazon has them for cheap, but so does Fred Meyer or your local equivalent). One magnet in the muslin bag with the hops, and one on the outside of the fermonster, set up after you pitch yeast. If you're dry hopping with more than 2oz, use multiple bags/magnets; the most I will go in one bag is 3oz. Once you're ready to dry hop, either move the outside magnet down the outside of the fermonster so the bag is under the beer, or just pull it off altogether so it plops down. No oxygen, and saves a bit of time, if like me, you suddenly look at the calendar and realize it's time to dry hop RIGHT NOW and have to get it all set up quickly.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)