Interesting. Would like to see pictures after collecting!

Me too. Will post pictures and result.

Interesting. Would like to see pictures after collecting!

Read the link, last post previous page, describes the build. It is not a dome, but a sandwich with a dip tube in it. The large surface area on top filters a lot, screen below tube gets the rest. Kal at the electric brewery has some more info on it also.

The trick with these is to slow the flow once the top is exposed as you do not have wort pushing down. I monitor the output hose and ensure the pump is not pulling to fast

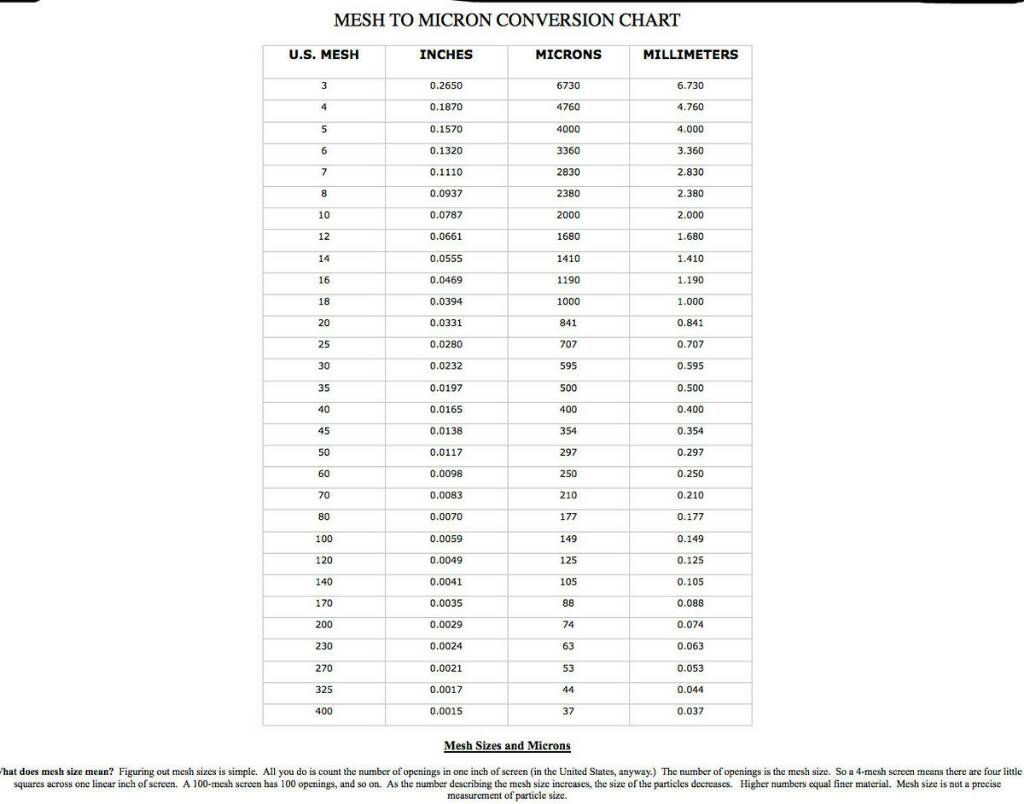

28x28 mesh is around 620 microns. Mesh size is just another measure system.

Good point, so 28x28 mesh with .01 wire equals .0257 in opening, which is 652.78 micron, 300 micron for reference is .0118 in openingthe mesh size calls out the number of openings per inch in the screen.

the width/diameter of the wire that the screen is made from also affects the size of the opening.

that table looks like the mesh are made with varying gauge wires.

How'd this filter work out?

How'd this filter work out?

No worries, its all good, there are other reasons like yeast collecting, the yeast you get from having clear wort in the fermenter is awesome, no need to wash it, just put it in a jar and repitch it. Also sometimes if you have trub it can coat the yeast and lead to less than stellar fermentation.

Sounds like a lot of time and at least some additional risk of infection for very little gain. Unless you brew really small batches, an extra quart isn't worth bothering with, IMHO.I've recently started screening the trub remains to extract the final wort. I use a huge funnel with a screen. I should take some pics this weekend.

For years I only let the kettle settle during the IC process...then I would open the spigot and pour thru a screened funnel into the fermenter until the screen clogged. Dump the first trub clog and then drain the rest of the kettle thru the same screened funnel until the very bottom trub gets pulled into the spigot once the kettle starts to bottom out. The rest gets tossed out, along with some good wort

The last couple batches I've taken all that trub that got tossed out before and poured it into a extra large mason jar and shake it up good. That gets poured into the same screened funnel but into another jar. As soon as the screen clogs I take the stuff below and recycle it back into the funnel and then let everything drip thru the trub caked screen into a clean jar. After it all drips thru I have a huge compacted solid trub cake on the screen and another good quart of pretty clean wort for the fermenter.

filtering that final trub takes few hours but I'm waiting for the ferm to hit pitching temps anyway. I simply reheat that quart on the stove real quick to re-sanitize it before adding it to the fermenter.

I agree with Jay a lot of extra work for a little bit, I'd either scale the batch up to account for the extra quart. OR if you are determined not to let any go, grab a 5 gal paint strainer bag and line a bucket fermenter with it before you transfer the wort. Then just lift the bag and remove the trub and hops that made it through a whirlpool.I've recently started screening the trub remains to extract the final wort. I use a huge funnel with a screen. I should take some pics this weekend.

For years I only let the kettle settle during the IC process...then I would open the spigot and pour thru a screened funnel into the fermenter until the screen clogged. Dump the first trub clog and then drain the rest of the kettle thru the same screened funnel until the very bottom trub gets pulled into the spigot once the kettle starts to bottom out. The rest gets tossed out, along with some good wort

The last couple batches I've taken all that trub that got tossed out before and poured it into a extra large mason jar and shake it up good. That gets poured into the same screened funnel but into another jar. As soon as the screen clogs I take the stuff below and recycle it back into the funnel and then let everything drip thru the trub caked screen into a clean jar. After it all drips thru I have a huge compacted solid trub cake on the screen and another good quart of pretty clean wort for the fermenter.

filtering that final trub takes few hours but I'm waiting for the ferm to hit pitching temps anyway. I simply reheat that quart on the stove real quick to re-sanitize it before adding it to the fermenter.

I've done it both ways on the same house recipe and didn't notice any difference. I now normally just drain my kettle until the siphon is broken. No whirlpool, and only settling is while I clean the IC (~5min). I'm not throwing everything in, but I don't go to any extra lengths to keep it out either. No problems of stalling as been mentioned, because they don't sit around long enough...well after finding brulosophy's truby experiment...I'm tempted to try a batch with everything dumper into the fermenter...

each brew day is an adventure...as will my upcoming biab experience