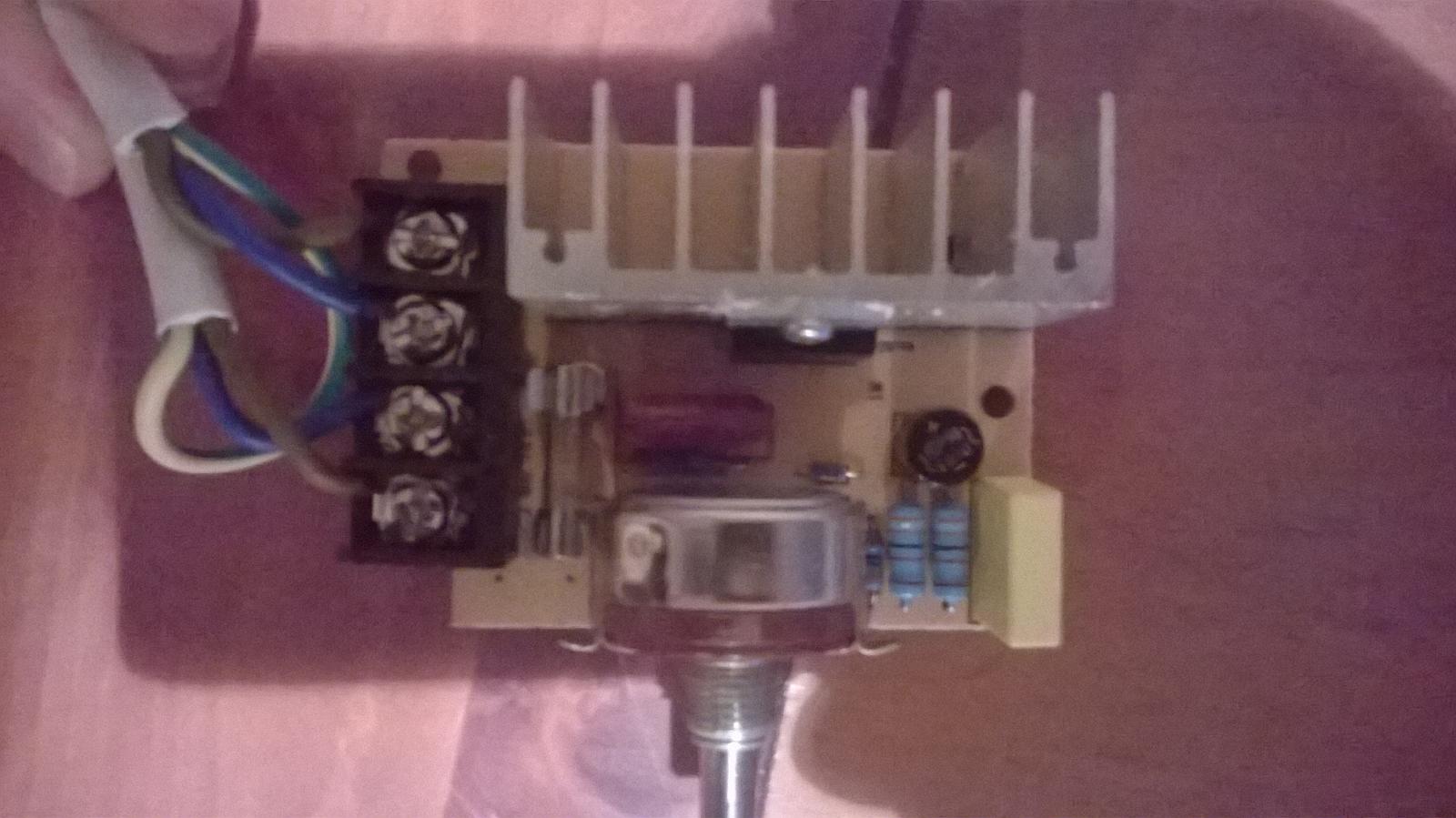

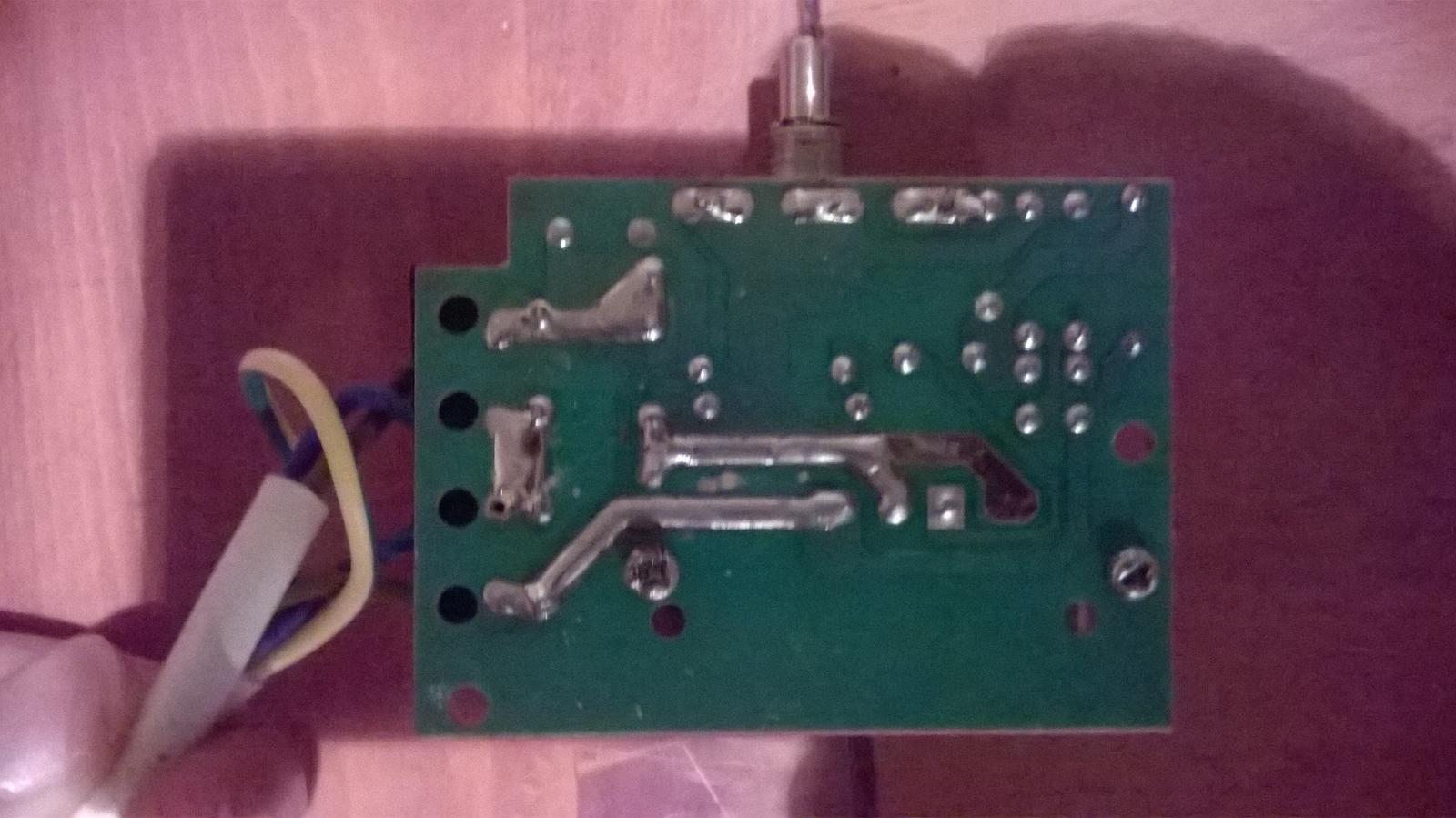

Bought one of these last night, since it was cheaper than buying the parts to build one.

http://www.ebay.com/itm/400775988169

Who has used these triac or phase angle controllers? Did you find them to be adequate for controlling the boil?

I've used a router speed controller in the past, which is essentially the same thing. However since I'm upgrading to 240v, I needed something that was rated for such, not 120v.

Sent from my iPhone using Home Brew

http://www.ebay.com/itm/400775988169

Who has used these triac or phase angle controllers? Did you find them to be adequate for controlling the boil?

I've used a router speed controller in the past, which is essentially the same thing. However since I'm upgrading to 240v, I needed something that was rated for such, not 120v.

Sent from my iPhone using Home Brew

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)