bracconiere

Jolly Alcoholic - In Remembrance 2023

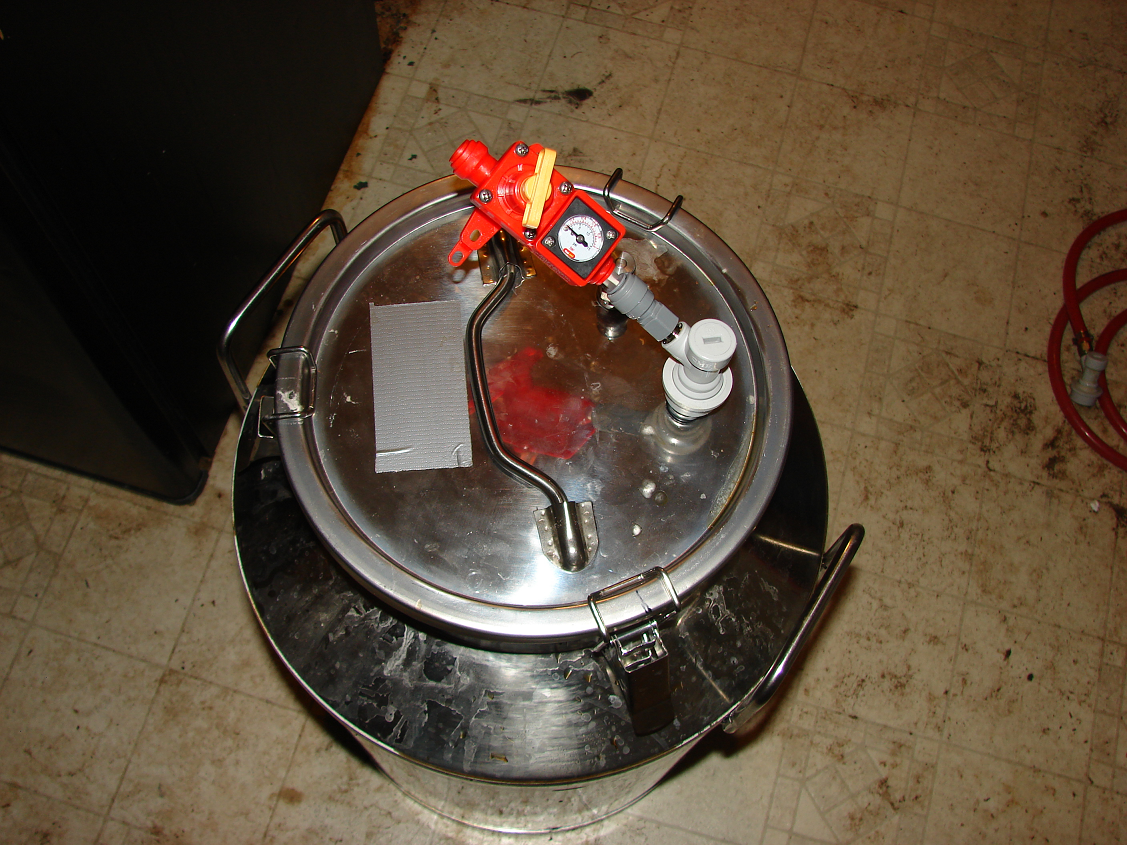

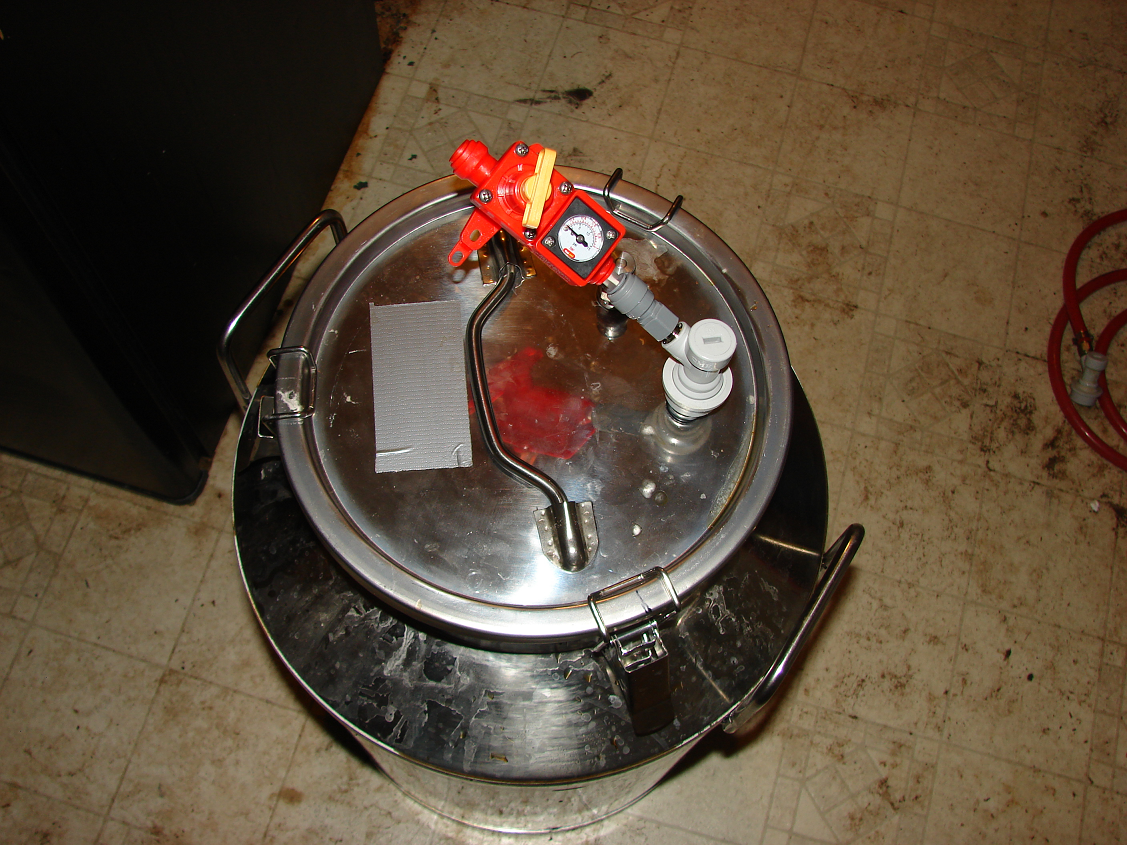

so focus on the equipment, not sanitation in this...

right now this thing is holding 8 psi, and still fermenting....

but i would feel so much safer with it in the house if i could figure out if there was a way to use a tri clamp, in stead of the clamps....according to doug, that lid is holding back like 700lbs of force right now....i'm not worried about the metal failing. but those clamps give me the creeps....

right now this thing is holding 8 psi, and still fermenting....

but i would feel so much safer with it in the house if i could figure out if there was a way to use a tri clamp, in stead of the clamps....according to doug, that lid is holding back like 700lbs of force right now....i'm not worried about the metal failing. but those clamps give me the creeps....

)

)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)