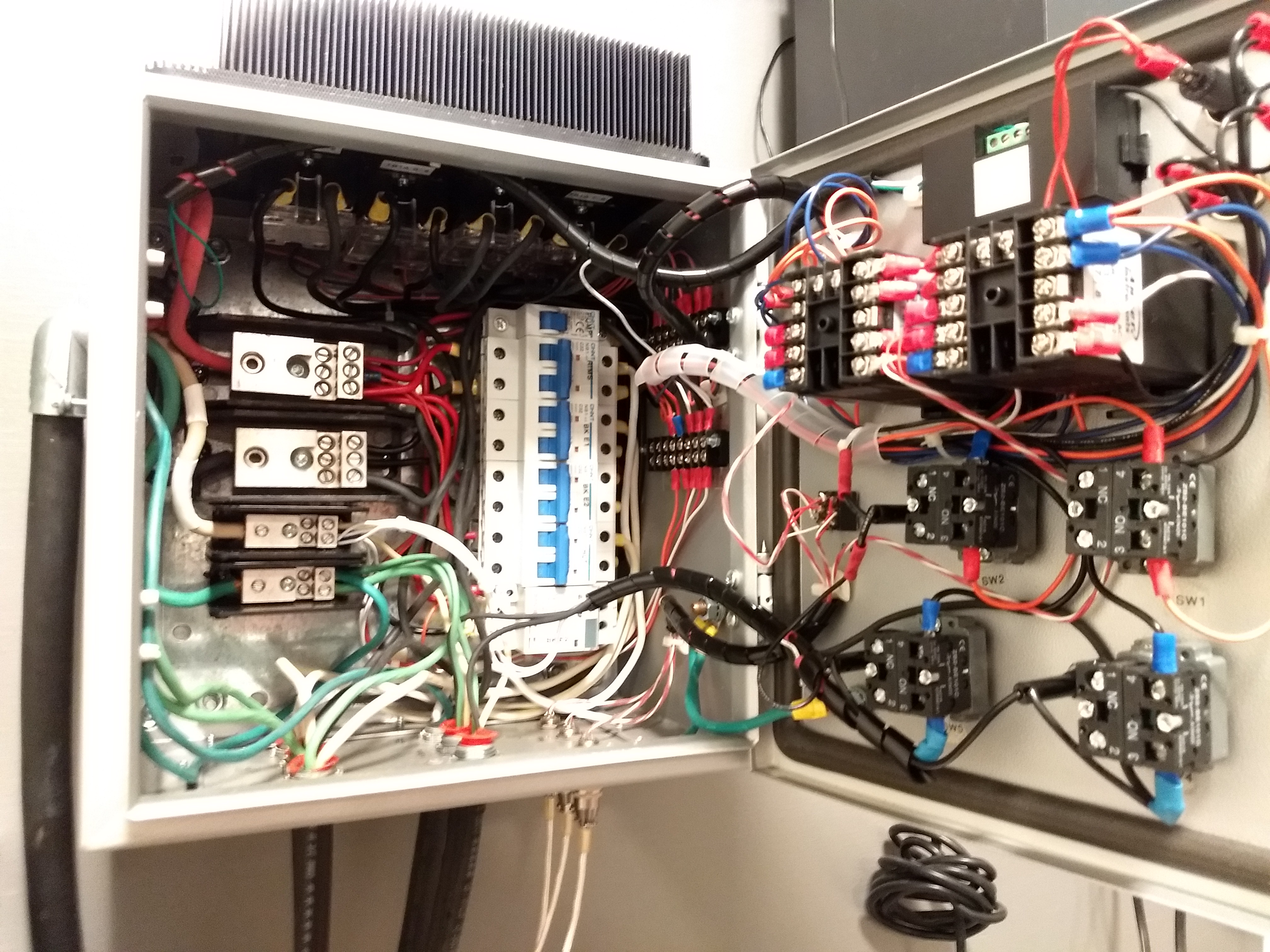

I've used both, a standard PID controller on a friend's RIMS system and an EZ Boil DSPR320 on my new eBIAB system and I think both types have their merits. I like the fact that the EZ Boil just works and it is not necessary to run an autotune loop to get non-oscillating strike and mash temps. But I built my own system using primarily Auber and BrewHardware parts, and it uses the two alarm dry contacts on the DSPR320 to automate the pump and chiller on my system. It's programmed to pre-heat my strike water to my dough-in temp (usually for a protein rest) and then hold until I press the Run button and times down through that rest, raise the temp to the mash rest and hold that temp for a pre-set time (usually 60 minutes), raise the temp to 172 for mash out/sparge, hold for removing the bag/basket and then bring to a boil (preventing boil-overs as has been described) and hold for a set time (usually 1 hour). At 15 minutes prior to the end of the boil, it activates the pump again to sanitize the plate chiller and at the end of boil, activates the cold water solenoid to chill the wort down. My DIY panel includes two way selector switches to control the pump and solenoid as Auto (AUX1 = AL1 and AUX2 = AL2), Off or On, so I can manually control those circuits when desired.

Clearly, you don't need to go to that level of automation, but there is that possibility if you wish to. Programming the DSPR320 is not particularly intuitive, but it's not too bad once you understand the logic. I would say that the EZ Boil controllers are definitely worth considering, unless you want to control an induction plate. To regulate output, the EZ Boil cycles much faster than a typical PID controller, and that would likely not work well with induction plate circuitry. But if you plan to have it control a standard water heater element or Boil Coil, I think it has quite a few merits.

Auber sells a pre-built "Cube 2E" controller with the DSPR320 EZ Boil controller, so if you are not VERY familiar with electricity and electrical safety, it might be a good way to go.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)