TOP DRAW FLOATING DIP TUBE PROBLEM

https://www.williamsbrewing.com/Top-Draw-Beer-Pick-Up-Tube-P4643.aspx

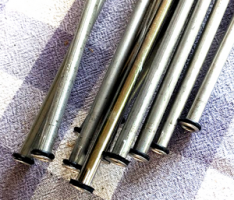

Let me start by saying I love these floating dip tubes. This is particularly true since I started Spunding in kegs to naturally carbonate the beer and no longer have to worry about sediment. However, after outfitting 5 kegs, I am encountering a problem. When I tapped by last 2 kegs, all I got was CO2 coming out. When I opened the kegs, the flexible tubing was floating on the surface of the beer with the the end of the tube on its side. It was not hanging down in a "U" like in the picture below. Instead, the tubing was floating and hugging the sides of the keg. As a result, the open end of the tube connected to the floating ball was not submerged. So, when I opened the tap, I was just getting CO2 from the headspace.

To fix the problem, I use a sterilized SS spoon to submerge the tubing which fills it with beer and causes it to work like shown in the photo below. After that, I don't have any problems with the keg for as long as it lasts.

I transfer my beer from my fermenter to my keg through the beer out, floating dip tube. so I'm not sure why it would end up floating on the surface. In addition, I spund in the keg, so either transfer before fermentation is complete or I add sugar water to the keg before I close it up and transfer.. It is frustrating having to open the keg to submerge the tube because this defeats one of the purposes for spunding which is to reduce oxygen exposure. I have thought about getting SS washers to weigh the tube down, but question whether there might be a better way.

Given the wealth of knowledge and creativity here, I thought I would ask if any one else has had this problem and if anyone has any potential solutions. If I try washers, I will let you know the results. Thanks.

Ugggh, I can't believe I mis-typed the title and can't fix it now.

https://www.williamsbrewing.com/Top-Draw-Beer-Pick-Up-Tube-P4643.aspx

Let me start by saying I love these floating dip tubes. This is particularly true since I started Spunding in kegs to naturally carbonate the beer and no longer have to worry about sediment. However, after outfitting 5 kegs, I am encountering a problem. When I tapped by last 2 kegs, all I got was CO2 coming out. When I opened the kegs, the flexible tubing was floating on the surface of the beer with the the end of the tube on its side. It was not hanging down in a "U" like in the picture below. Instead, the tubing was floating and hugging the sides of the keg. As a result, the open end of the tube connected to the floating ball was not submerged. So, when I opened the tap, I was just getting CO2 from the headspace.

To fix the problem, I use a sterilized SS spoon to submerge the tubing which fills it with beer and causes it to work like shown in the photo below. After that, I don't have any problems with the keg for as long as it lasts.

I transfer my beer from my fermenter to my keg through the beer out, floating dip tube. so I'm not sure why it would end up floating on the surface. In addition, I spund in the keg, so either transfer before fermentation is complete or I add sugar water to the keg before I close it up and transfer.. It is frustrating having to open the keg to submerge the tube because this defeats one of the purposes for spunding which is to reduce oxygen exposure. I have thought about getting SS washers to weigh the tube down, but question whether there might be a better way.

Given the wealth of knowledge and creativity here, I thought I would ask if any one else has had this problem and if anyone has any potential solutions. If I try washers, I will let you know the results. Thanks.

Ugggh, I can't believe I mis-typed the title and can't fix it now.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)