jnesselrode

Well-Known Member

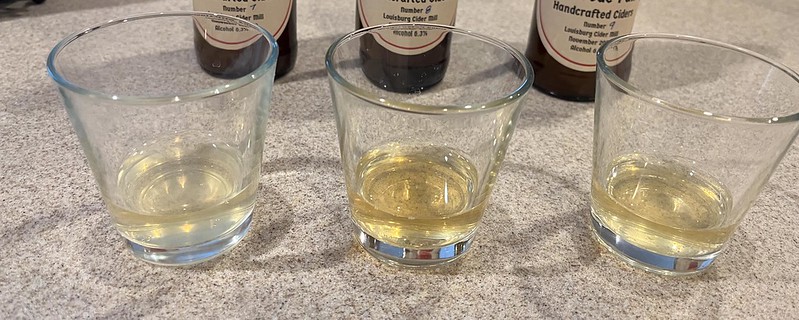

After asking questions here and reading up a bit, I decided I'd do an experiment in order to try for something like the more-flavorful ciders like we experienced in Ireland.

I'm not going to be able to start with apples, so I'm going with Louisburg Cider Mill (Kansas, USA) cider, which is probably a typical drinking cider found in the US. I have boosted the acid and tannin levels above where I have typically done in previous batches, and know I can adjust up after fermentation if needed. I didn't add any sugar, as I'm hoping to keep alcohol level lower and retain as much apple flavor as possible. I didn't do TA or pH -- I figure I'll check that afterwards, but I have a general idea where this cider will be based on previous batches.

Today I started 3 one-gallon batches, each with a different yeast strain: Cotes des Blancs, Nottingham and Safale S-04. Here's the starting info:

1 gallon Louisburg Cider Mill cider

½ teaspoon acid blend

½ teaspoon pectic enzyme

¼ teaspoon tannin

1 teaspoon yeast nutrient

I'm not going to be able to start with apples, so I'm going with Louisburg Cider Mill (Kansas, USA) cider, which is probably a typical drinking cider found in the US. I have boosted the acid and tannin levels above where I have typically done in previous batches, and know I can adjust up after fermentation if needed. I didn't add any sugar, as I'm hoping to keep alcohol level lower and retain as much apple flavor as possible. I didn't do TA or pH -- I figure I'll check that afterwards, but I have a general idea where this cider will be based on previous batches.

Today I started 3 one-gallon batches, each with a different yeast strain: Cotes des Blancs, Nottingham and Safale S-04. Here's the starting info:

1 gallon Louisburg Cider Mill cider

½ teaspoon acid blend

½ teaspoon pectic enzyme

¼ teaspoon tannin

1 teaspoon yeast nutrient