bracconiere

Jolly Alcoholic - In Remembrance 2023

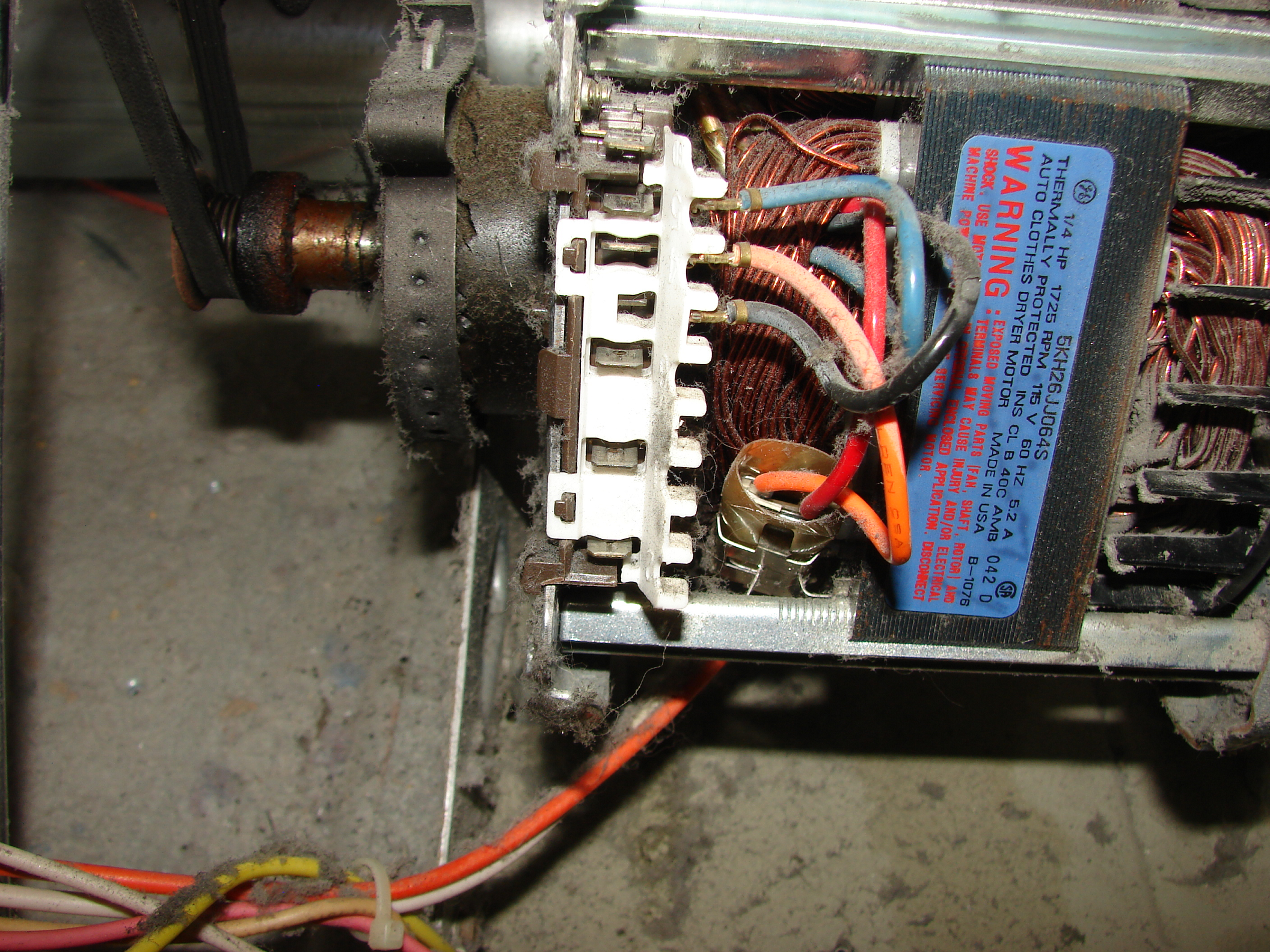

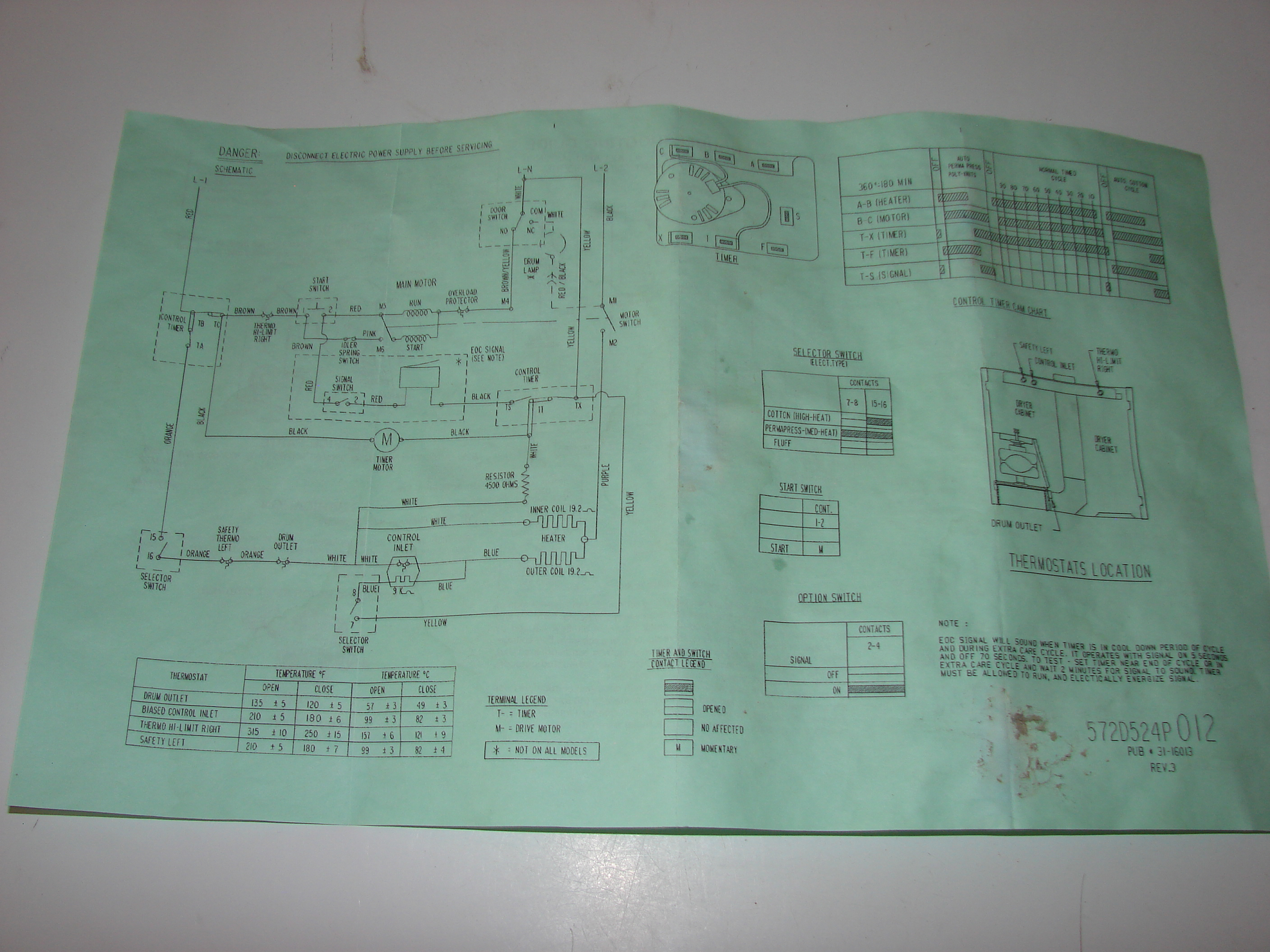

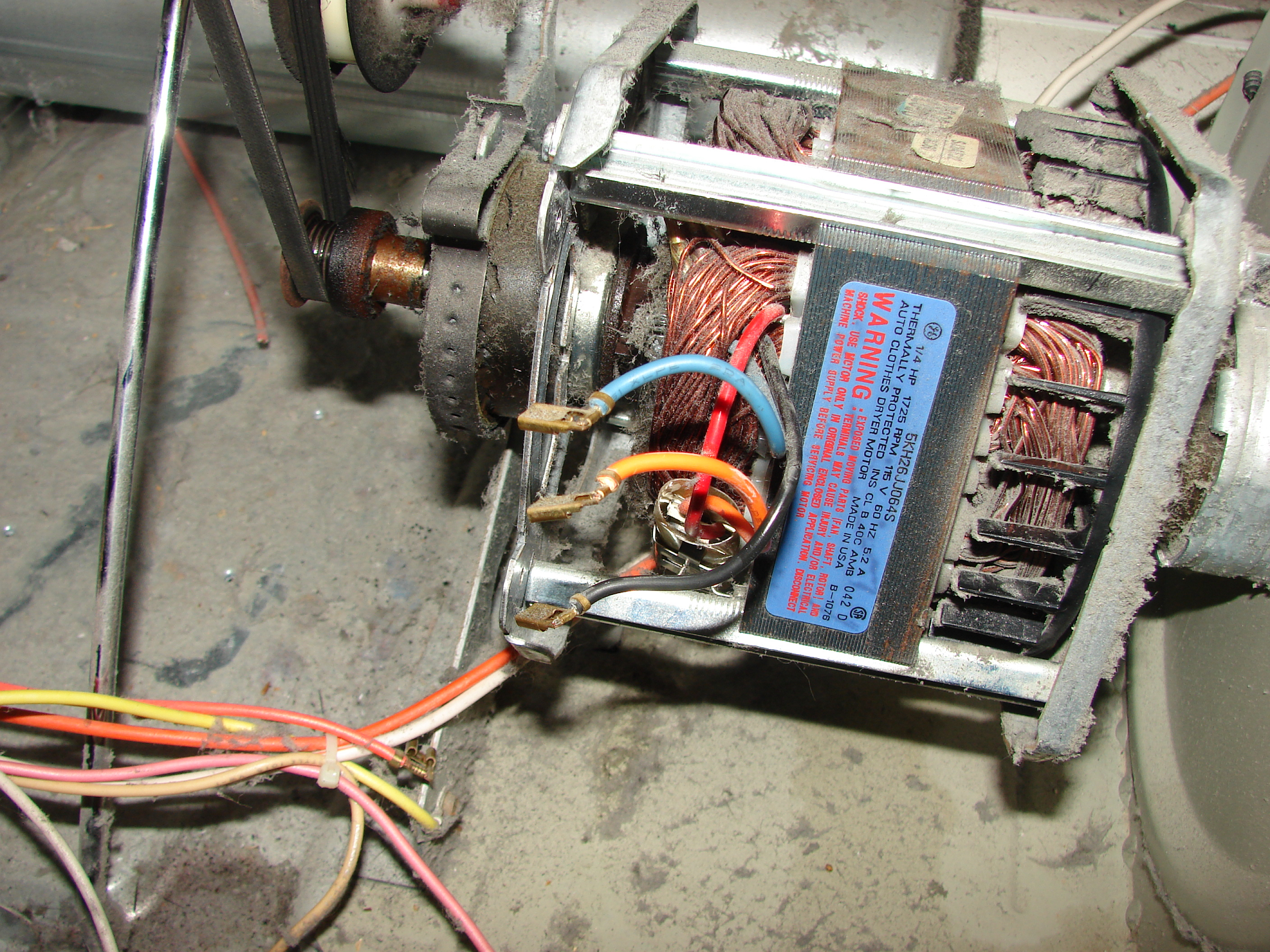

So i just scored a free dryer without a cord for deculming my malt the easy way....it has four wires, going to three terminals, no cord. i'd need a longer cord in way so i can put it on the back deck...but my dryer i have now uses a four wire plug? i was looking at cords for dryers and see there're are both 4 AND 3 wire plugs....this is what the dryer looks like..

what exactly do i need? will a four prong cord work with this dryer?

and if not can i somehow convert the drum, and fan to 120v? all i need is the thing to spin, and blow air over the malt.....

what exactly do i need? will a four prong cord work with this dryer?

and if not can i somehow convert the drum, and fan to 120v? all i need is the thing to spin, and blow air over the malt.....

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)