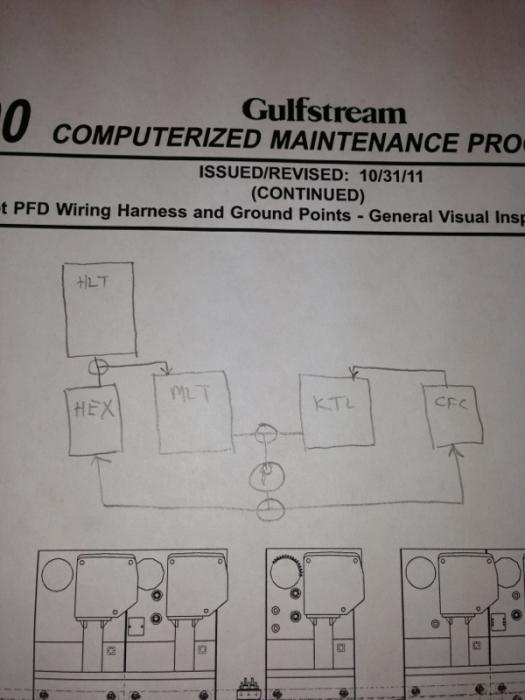

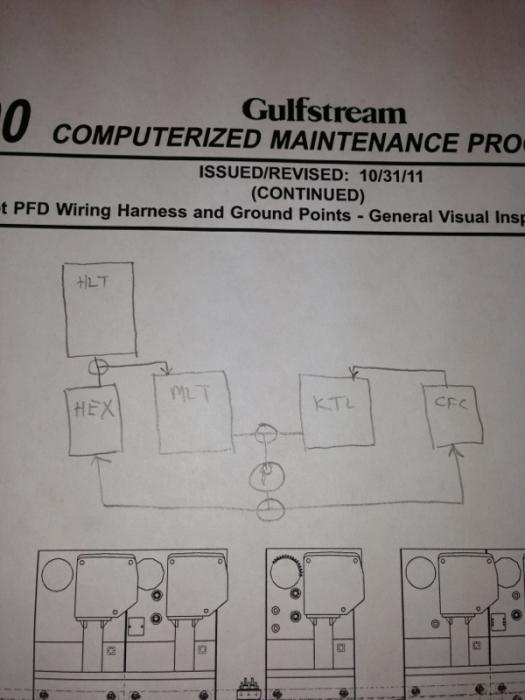

True, a smaller volume HEX-tank would allow the water temperature to heat up quicker, so temperature transfer to the coil and into the mash would have a quicker rise. It only takes a few minutes for my HLT to raise 10 or so degrees if I'm doing a step mash, which isn't a whole lot of time in the greater scheme of things, and is definitely better than having a 4th tank, another PID, and another heating element / plug. Your setup would definitely work with 4 tanks, it's just not what I would chose.

There should be no issue flowing through the CFC. You'll end up leaving a lot of wort behind, depending on how long the CFC is / what diameter tubing you use. So when you're sparging, your final runnings will sit in the CFC until you start recirculating the BK through the CFC to sanatize everything with heat (assuming that's the process you're going with).

I wouldn't count on the CFC to provide the resistance you need to get the right flow while sparging - put a valve on the outlet of your pump and use tha to throttle your flow.

As for going with electric valves eventually - unfortunately, I had the same thought once upon a time (as have others) and not once has anyone been able to find a true 3-way valve. All the electric 3-way valves on the market will allow you to switch between Flow A or Flow B, but none of them allow Flow A, Flow B, or Off (no flow). This may not be a big issue to you, or you may be the lucky one to find the ever ellusive valve, but something to consider before you get too far into a design that may not work for your eventual end goal.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)