Twelve days ago this was grain…

I've been asked more than a few times about my COVID Panther Piss Project and what I'm doing to produce clear N.American premium lagers in about fourteen days. I've never been secretive about what I'm up to, there are remarks and descriptions scattered all over the site and across many private messages. Nevertheless, I've always been a bit reluctant to formally write up my findings and process because my techniques and processes evolved steadily over the roughly 4.5 years during which the project was in active development.

I decided about a year ago that I didn't have much room left for improvement for the Panther Piss Project, so I let it go into hibernation while I went back to brewing UK ales. I deserved a break after having 3-4 kegs of Panther Piss on draft for 4+ years!

I recently brewed a new batch of Panther Piss and one of our site mods suggested that I should write up the process. I thought about it and decided, “Yeah, why not?” Now is a good time. I haven't worked on it in a year, so things are no longer developing and I recently brewed it and demonstrated that it still works. So why not?

At its core, this isn't a recipe. Rather, it is a process. There are no silver bullets in home brewing. If you use the recipe without following the process you're not going to succeed. The process is what makes the results possible, not the recipe! I cannot stress that enough. It's just a boring 20% corn/10% rice fizzy yellow swill. The recipe has no attributes that will encourage clear lager in fourteen days. This is all about the process.

To make this process work, you're going to need a calibrated, accurate, and fast working pH meter. I suggest the Apera pH60, it's the finest brewing pH meter that I've ever used—and I've used many. You'll also need accurate and reliable fermentation temperature control and a reliable anti-suck back rig for your fermenter to avoid oxygen ingress during the crash. A keg equipped with a floating dip tube is a must, as is some comfort with with LOw Dissolved Oxygen (LODO) techniques.

Some words about LODO

Prior to posting this write up I ran a draft past a number of HBT readers, each with a reputation as an excellent brewer. Almost all of them suggested that I should offer some explanation about why I'm using LODO techniques and how I'm applying them. Fearing that this post might devolve into a discussion about the merits of LODO, I was hoping to avoid doing that. Nevertheless, I'd be a fool to ignore suggestions from such talented brewers.

So, here's how I'll handle this. First,I'll provide my reasoning for turning to LODO techniques during the course of the Panther Piss Project. Next, I want to avoid going into the nuts and bolts of how to use LODO techniques. The first draft of this write up ended up spanning ten pages and 6,000 words. Publishing that on HBT simply isn't practicable. Here are two (1, 2) excellent links from The **************** that do a great job describing the goal and techniques of LODO. Also, check out HBT's own LODO sub-section. That should get you going.

The Rationale: I didn't start the Panther Piss Project with LODO. Instead, I turned to LODO to address a couple problems that emerged during the project. The goal of the project was to make a better fizzy yellow swill than BudMillerCoors and do it within their production time frame. Although my recipe cheats a bit by raising the OG into premium N. American territory and uses some fancy Continental malt; with 30% of the grist given over to adjuncts and an additional 27% occupied by domestic 6-row malt, that leaves a paltry 35% of the grist available to provide substantive malt flavor. LODO's hot-side oxygen mitigation techniques, as I found out, excel at preserving malt flavor and getting it to where it matters most, your glass. Also, fizzy yellow swill is murderously light in color. If any oxygen sneaks in during your packaging process you'll see it in your finished beer's darkened color, hence the need for closed transfer techniques while packaging. Further, the closed transfer technique also preserves the freshness of the beer's flavor when packaged. LODO played an important part in the success of this project because it helped to get the beer tasting great and looking right throughout its time in the serving keg.

The LODO Techniques I Employ. Due to the format of this forum, I'm most concerned with brevity. Feel free to ask for clarification below. Note that I'm not running a full LODO brewery. Proper LODO brewers will identify areas where the Panther Piss Project diverges from proper LODO techniques. I'm employing LODO in this context to achieve the project's two fold objective: 1) Good fizzy yellow swill in 2) Fourteen days. I freely admit that I'm doing it wrong, perhaps even doing LODO a disservice. Again, this should not be taken as a primer on the correct way to do LODO brewing--I'm not the guy for that! I'm not making the ideal Helles here, instead I'm blasting out fizzy yellow swill on a very tight timeframe.

- I employ Yeast Oxygen Scavenging (YOS). This greatly reduces the amount of oxygen in your strike and sparge liquors. To do this, you simply build your brewing liquor the night before brew day, adding your Campden, salts, acid charges, and 1g/gallon of cheap bread yeast and 1g/gallon of table sugar to your strike and sparge volumes. Overnight, the yeast will absorb the available oxygen in your strike water as they prepare to go after that sugar. The next morning you simply fire up your brewery as normal. There are other ways of doing this, but this is how I do it.

- I employ caps on all my vessels. Caps are cheap and simple, they're just a lid that floats on top of any liquor or wort prior to boiling. My initial caps were Reflectix insulation (I had a spare roll laying around, okay?). I've since moved on to using closed cell foam caps that I've cut out of a cheap yoga mat, much better!

- I underlet my mashes and I employ a subsurface manifold to sparge my mash.

- I employ a mixture of three sacrificial antioxidants in both the mash and the boil. This mixture of antioxidants, dubbed the "trifecta blend" or just "trifecta," react more readily with oxygen than your malt, so they clear up any remaining oxygen that evaded the YOS charge or was introduced during the strike. Here's a link to @cmac62's antioxidant recipe [or see the content of that post, below -Mod].*

- Finally, I package all my beers via the pressure transfer method which greatly reduces the amount of oxygen ingress suffered during packaging. I also treat my keg with 1/4 tsp of ascorbic acid (vitamin C) to sop up any oxygen that managed to squeak its way into the keg during the transfer. If the closed transfer is performed correctly, the ascorbic acid likely isn't necessary, but it's cheap and convenient insurance.

- The proper LODO method suggests krausening is the ideal carbonation method, but the Panther Piss Project has a hard deadline to make, so I force carbonate and also rely on the lager's already partially carbonated state due to its brief stay in the fermenter and its cold, CO2-retaining temperature.

For the last few brews I have been adding some K-Meta to the boil as part of the K-Meta, Ascorbic Acid and BTB as a trifecta to help reduce the oxidative effects. I have been getting a sulfur smell (ie. rotten eggs). There is no flavor, but the smell is off-putting to say the least. Is this due to the K-Meta (too much or not at the right time)?

On to the Panther Piss Process

Here is the process, in as stripped down a format as I can manage. I've been through several drafts of this post (some stretching out to ten pages) so I've opted to prioritize brevity over clarity. Don't be bashful about asking questions, I'll answer them as best I can.

Here's the process that I use to make Panther Piss:

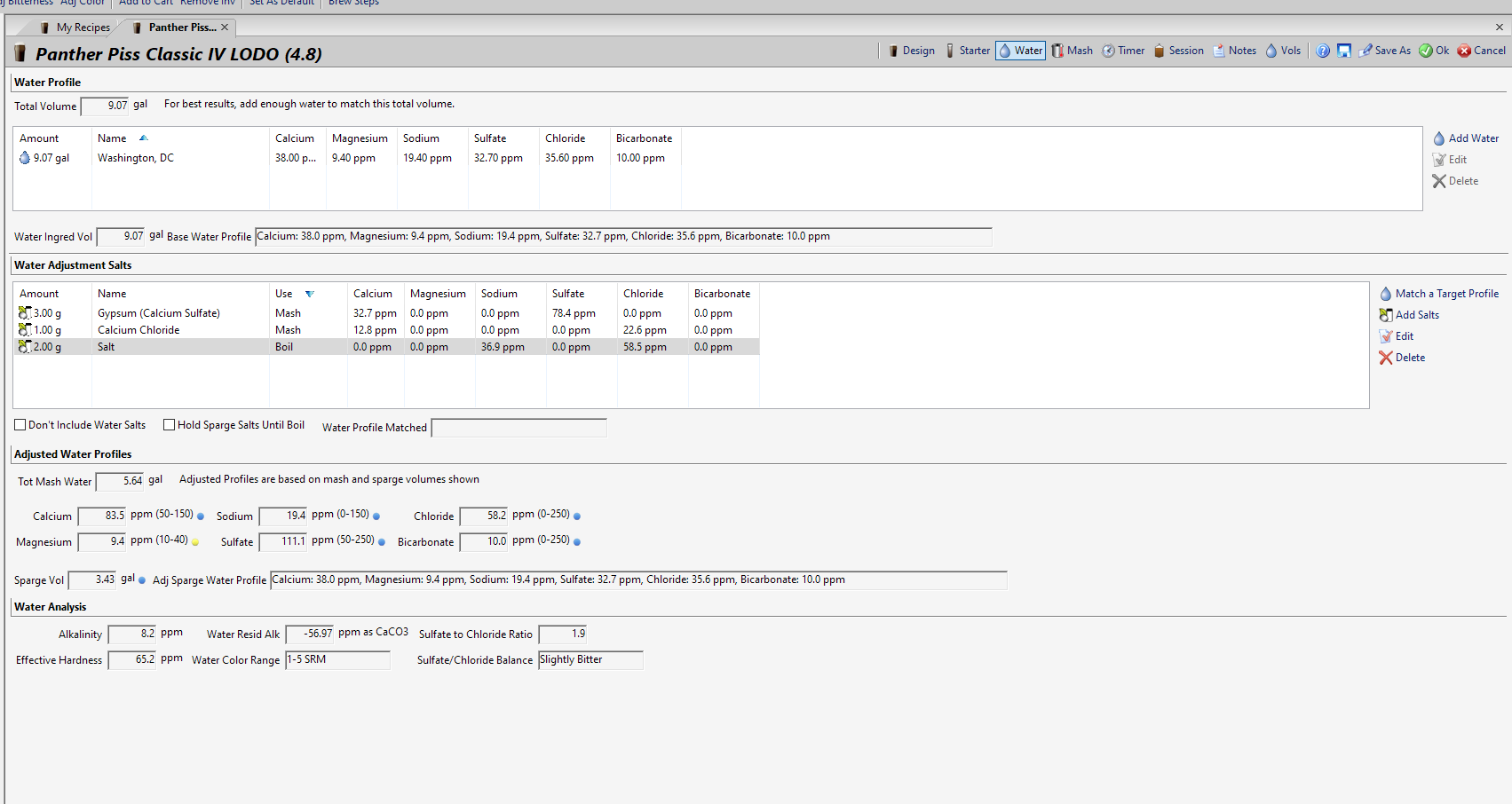

- Set up a normal LODO brewing session the night before by building your water with campden, salts, acid additions, and YOS charges in the appropriate vessels. Target a mash pH of pH 5.4 and over-acidify your sparge water to target a pre-boil entire runnings pH of pH 5.2.

- On brew day, condition your malt and mill it. I believe conditioning is important because it produces a better, more effective filter media and reduces the amount of particulate material that makes its way into your kettle. If you can filter it now you don't have to deal with it later.

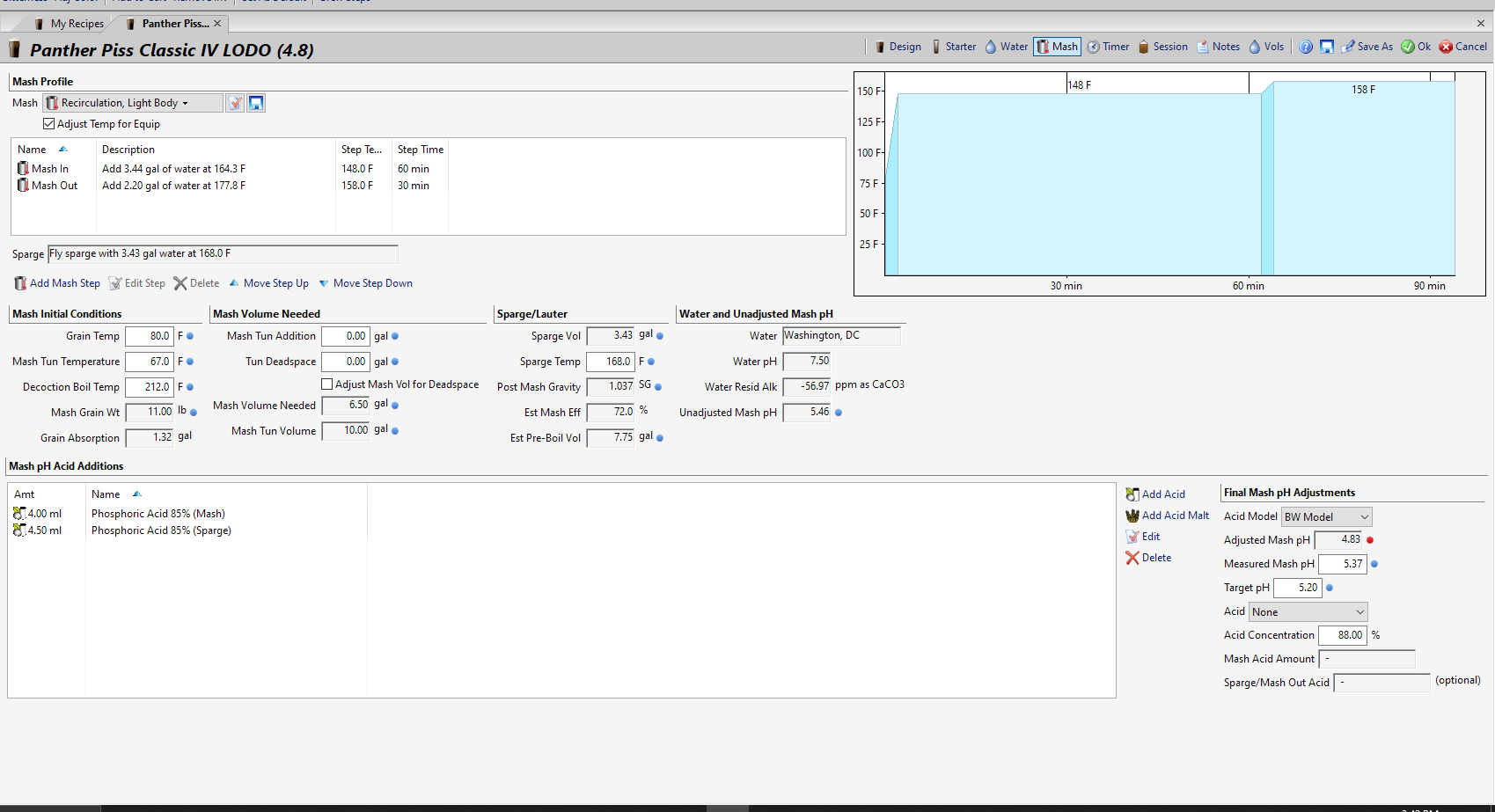

- Use LODO trifecta in your mash and employ a Hochkurz-eque infusion mash, striking at 148F(64.5C) for 60min, then infuse to 158F(70C) and recirculate for 30min to filter as much particulate matter as possible. This extended mash should net you a properly dry beer and excellent efficiency.

- Sparge and lauter as normal, using LODO techniques. Your pre-boil entire running should be very, very clear. Using 85% phosphoric acid, adjust your pre-boil pH to pH 5.2, typically no more than 1ml is necessary. You'll notice in the recipe sheets below that I decided to second guess my notes and I missed my pre-boil pH target. I use DC tap water and I sometimes miss my mark when I anticipate predictable, seasonal changes. This last batch was a prime example of that. Still, because I brew with a pH meter, I was able to get it right and achieve the correct result with acid additions later in the process. If I had been brewing with only a spreadsheet I would've missed that mistake and I'd be frustrated because my beer was hazy and I'd have no clue why.

- Boil for 90min, using a trifecta charge with your finings and yeast nutrient. Also add 1 ml of 85% phosphoric acid along with your finings, etc. Whirlpool while you chill and attempt to transfer the cleanest possible wort into your fermenter. Again, if you deal with it now, you don't have to deal with it later.

- Confirm that your post-boil pH is pH 5.0-5.1, adjust with a further 1-2 ml of acid if needed. Next, pitch two sachets of 34/70 or S-189. One will get the job done, but two will ensure we get the fermentation finished as quickly as possible. Oxygen is not needed on the initial pitch, but necessary on repitches. Use one drop of ionic zinc at pitching.

- Ferment using the “modern lager” technique. Pitch at 50F(10C), then allow the fermentation to free-rise to 52F(11.1C) once it establishes itself. Gradually allow the temp to free-rise in small, controlled increments until you hit 56F(13.3C) with ¼ of gravity remaining.

- Once the beer hits TG, crash the beer immediately and hold for 2-3 days. I have not found a D-rest to be necessary with 34/70 provided you pitch it big and healthy.

- With the beer crashed, keg into an oxygen purged keg using a closed circuit transfer. I prefer to pressure transfer, closed gravity transfers are beautifully elegant, but they lack reliability in my experience.

- Once racking is complete, dose your keg with 1/2 tsp of ascorbic acid and either gelatin (cheaper, more effective) or BioFine Clear (a bit less hassle, but expensive). I've used both with success. Perform the dosing by injecting the finings and ascorbic acid with a syringe through your gas in post.

- Pressurize your keg to 30psi and place it in your serving fridge, do not hook up your gas yet. Allow the keg to sit for two days, then hook up your gas and pour a glass. The first glass may be slightly cloudy, floating dip tubes tend to capture a bit of yeast during closed circuit racking. The second glass should be brilliantly clear. The carbonation should be slightly on the low side of the range, as I prefer. You may find it necessary to carbonate a bit more to suit your taste. If so, you may wish to put in on 40lbs of gas before putting it in the fridge. I've done that in the past and while I found it to work, the resulting beer was too gassy for my taste. I do not like even the merest hint of carbonic bite.

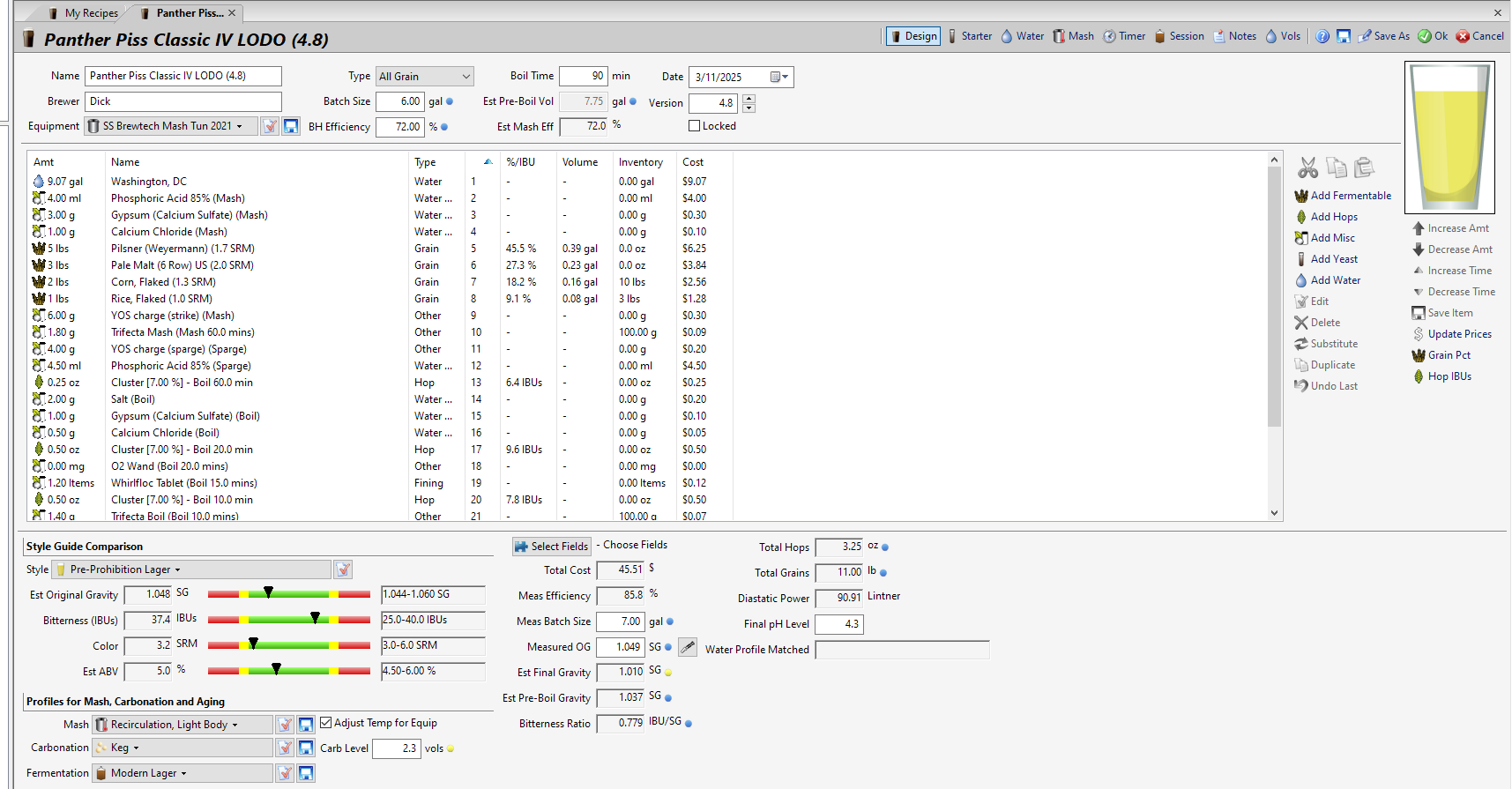

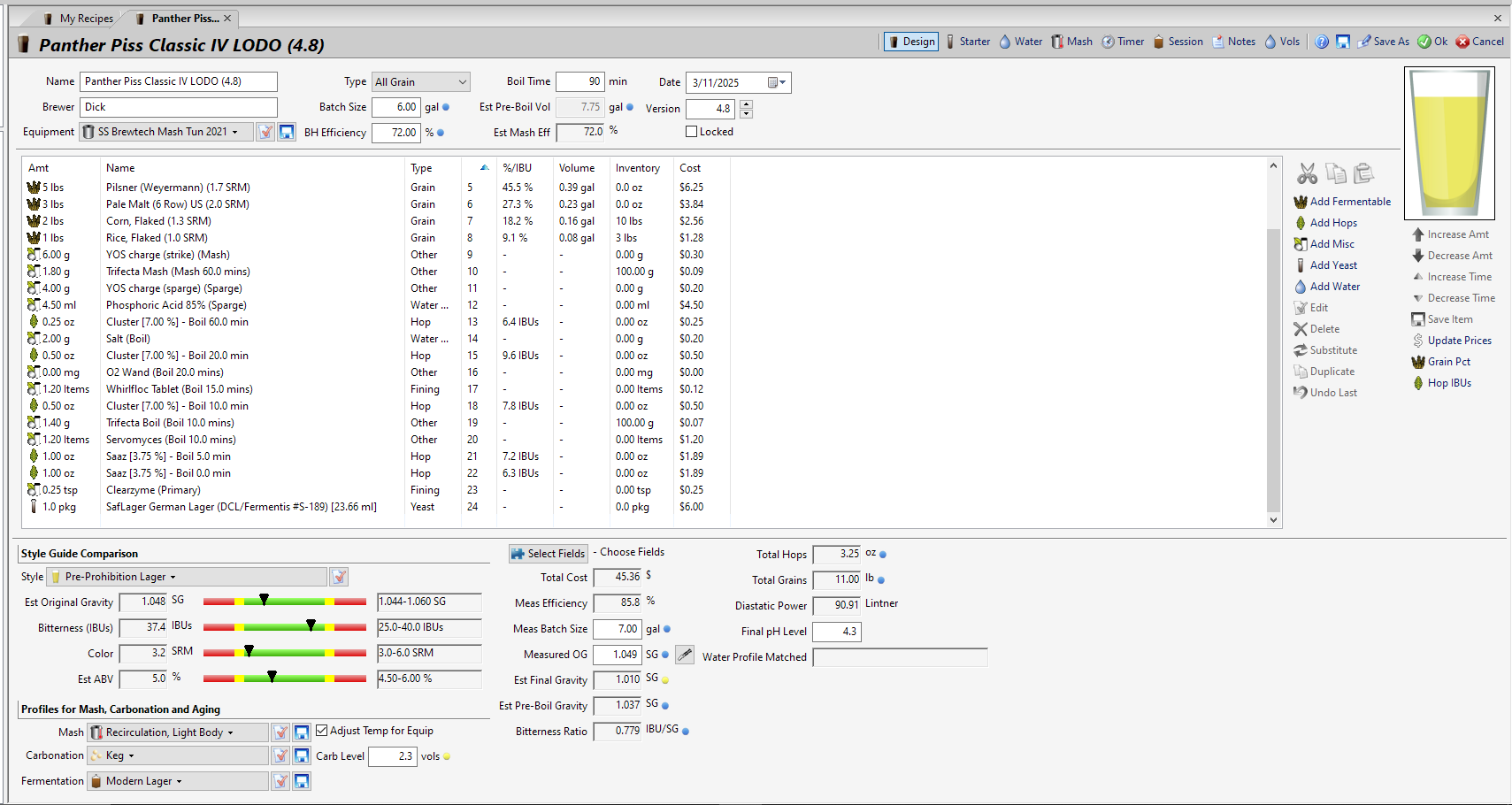

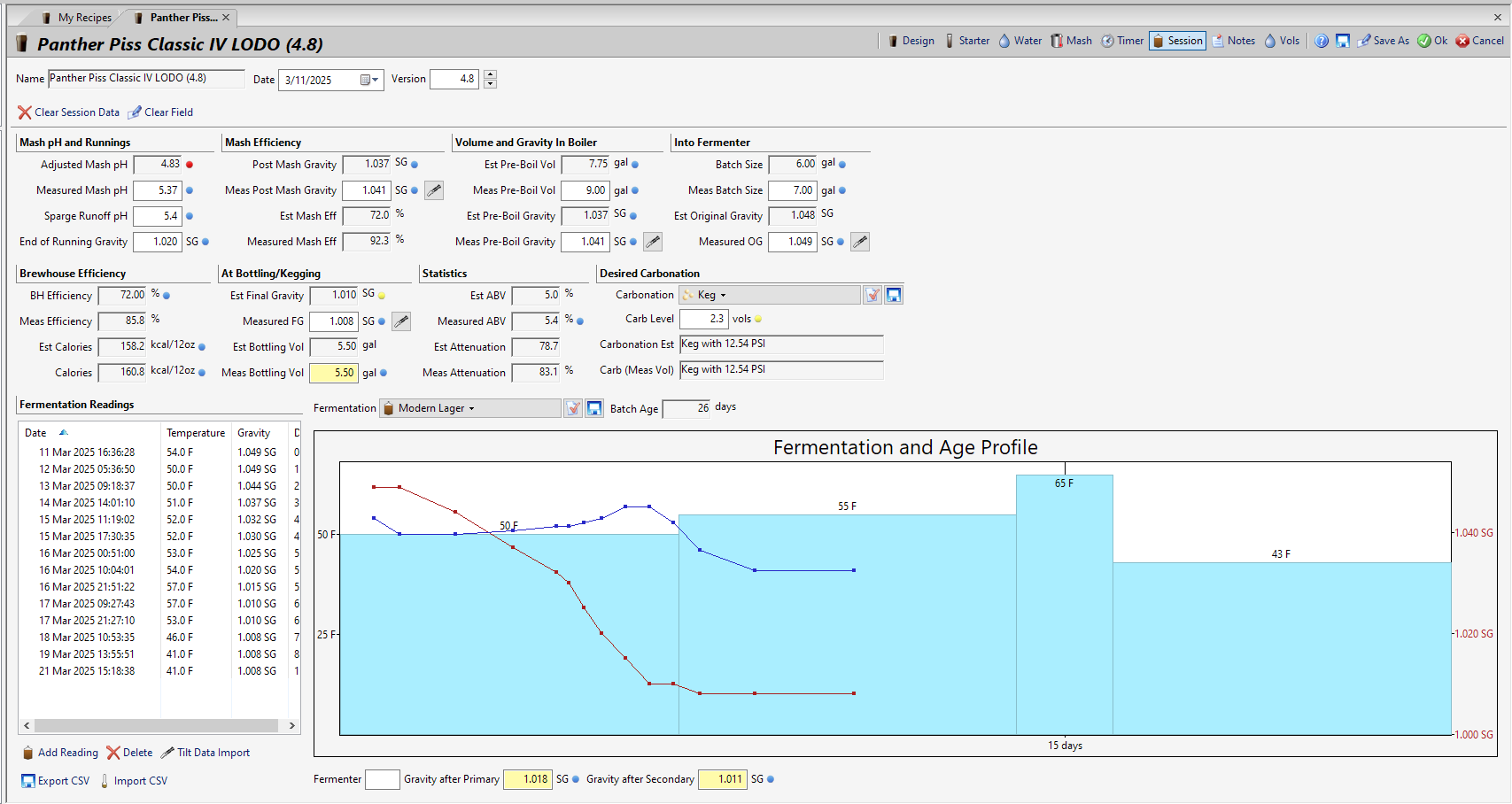

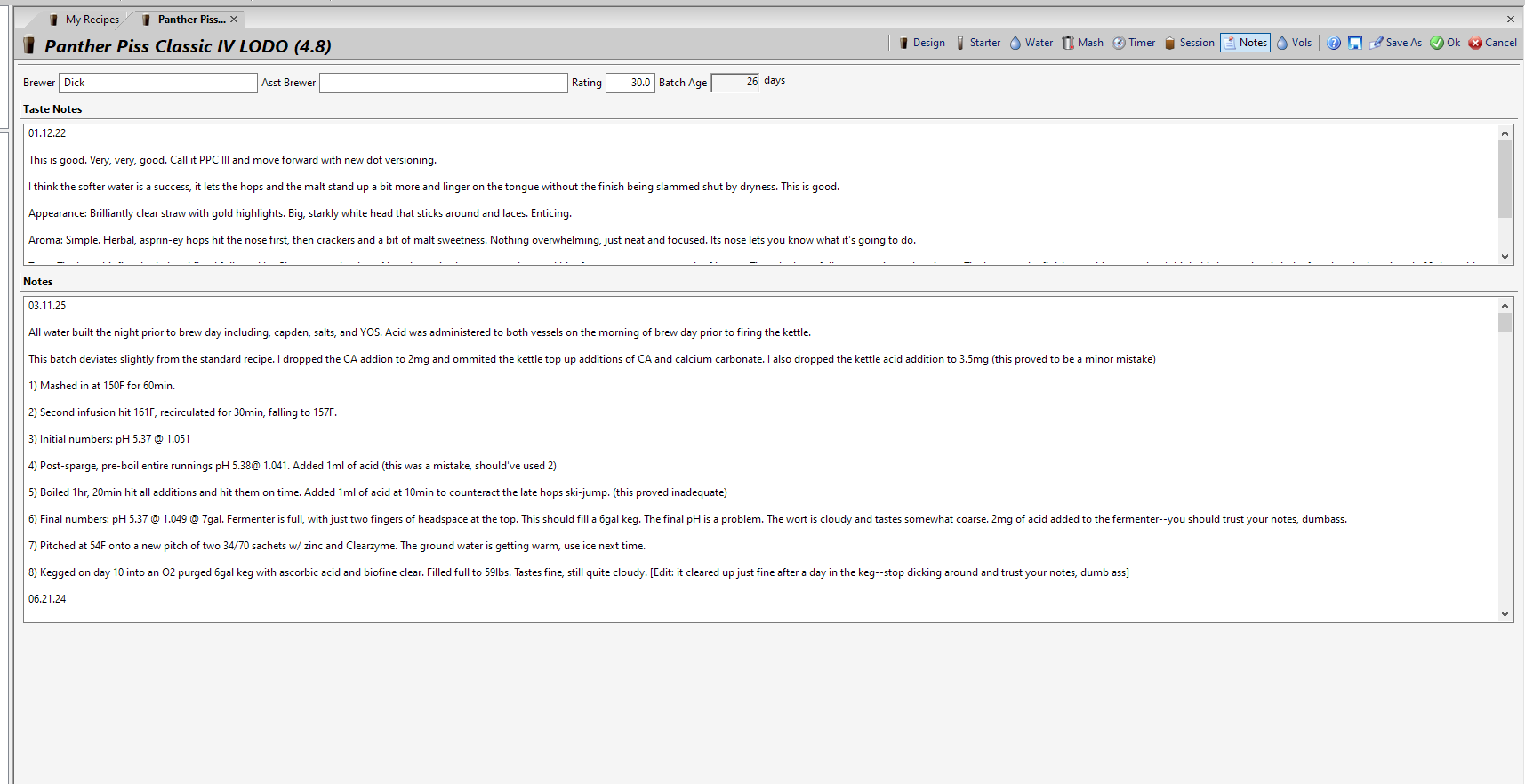

Here is the complete collection of BeerSmith recipe sheets from my most recent batch so you can follow along with the brew day—and laugh at my mistakes. Note that I'm still using the default efficiency setting in BS—I know how my system works and I'm too damned lazy to change it. I hope that doesn't cause any confusion. The correct, repeatable OG is 1.049 @7gal. I've also attempted to include the BeerSmith .bsmx file as an attachment--thank you, day_tripper! I've never done that before, give me a shout if I've screwed it up.

A Quick Word About Enzymes

During the Panther Piss Project I tried two enzymes sold by MoreBeer that are purported to promote clarity. The first, GlucaBuster is no longer marketed as a clarity enhancer. I didn't find it to be terribly useful, either in the mash tun or the finished glass of beer. The second, Clearzyme, works somewhat when you miss high on post-boil pH. But if you're racking into the fermenter at pH 5.0, I haven't noticed that it makes much difference. I've intentionally (and unintentionally) brewed Panther Piss both with and without these enzymes and I believe their contribution is marginal at best. I'll use up my remaining stock, but I don't plan to replenish them when I run out. Frankly, I believe that they're a waste of money.

Some Thank Yous Are In Order

Finally, I'd like to offer my thanks to doug293cz for encouraging me to write this up. You wouldn't be reading this if it weren't for him. He also kindly helped me to organize my initial thoughts and got me pointed the right way. Thank you, Doug! I'd also like to thank Hoppy2bmerry, MaxStout, day_tripper, and doug293cz for pre-reading my draft and offering excellent advice about the content of this write up. Their suggestions drastically improved this post. My sincere thanks!

Lastly, thank you for putting up with all of the formatting mistakes that have crept into this write up as it has bounced back and forth between a word processor and this forum's formatting. I've done my best, but I'm aware that some weirdness has crept through. I've run out of patience, so it's time to post this thing and be done with it. Thanks for putting up with it.

Attachments

Last edited by a moderator:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)