GreenMonti

Well-Known Member

- Joined

- Nov 29, 2009

- Messages

- 1,268

- Reaction score

- 67

GM, how far will your flash boiler be located from the mlt and boil kettle? You are working with 5-6' now. I assume you lose some heat as the steam travels that distance but one could tune the system to take that into account. Could it be further, 10'? Just have me thinking about a remotely located flash boiler outside the brewery.....

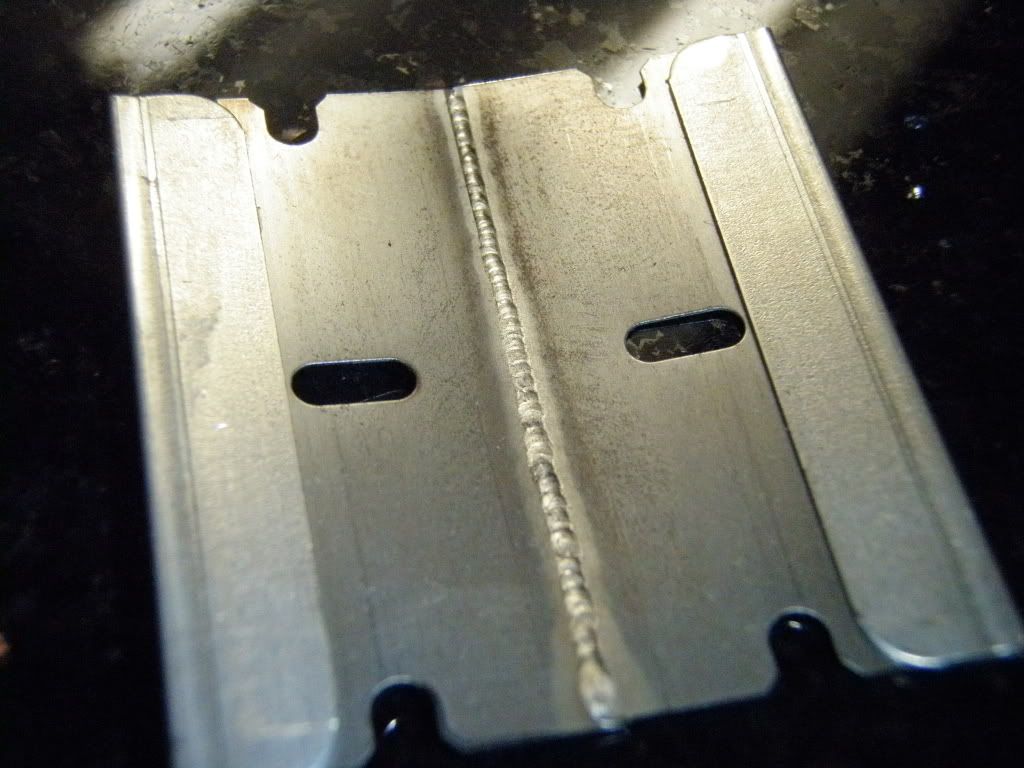

Yes, I am currently running 5-6' of steam line now. Though I am pushing a small amount of steam that distance. I would bet I'd be pushing my luck for boiling that far away. Just because of what you said. I would loose a bit to the steam line. Since I am not going full out with treated water to generate the steam with. I am not seeing the full potential of steam right now. I should see more power out of my steam if I was to de-aerate it. Steam can get pretty deep. I'm not doing any of that cause this is a simple home brew rig. I am also doing short run times and not very frequent runs of steam.

I'm setting my FB up just beyond a foot from the kettle and my MLT will be on the other side of the kettle. Though I don't plan on running the steam line all the way to the MLT. I am going to run it to the MLT recirculation line. My steam line for the MLT will do double duty, it will carry strike water, then I will make steam for the mash temps, then the same line will carry my sparge water.

I had several thoughts about placing my boiler remotely. This would solve a lot of problems with venting the propane. Then I thought about the steam vapors from my kettle and the MLT. I have to vent them anyway. I figure a hood over the brewing rig will take care of both needs. Just like a gas range in a kitchen.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)