GreenMonti

Well-Known Member

- Joined

- Nov 29, 2009

- Messages

- 1,268

- Reaction score

- 67

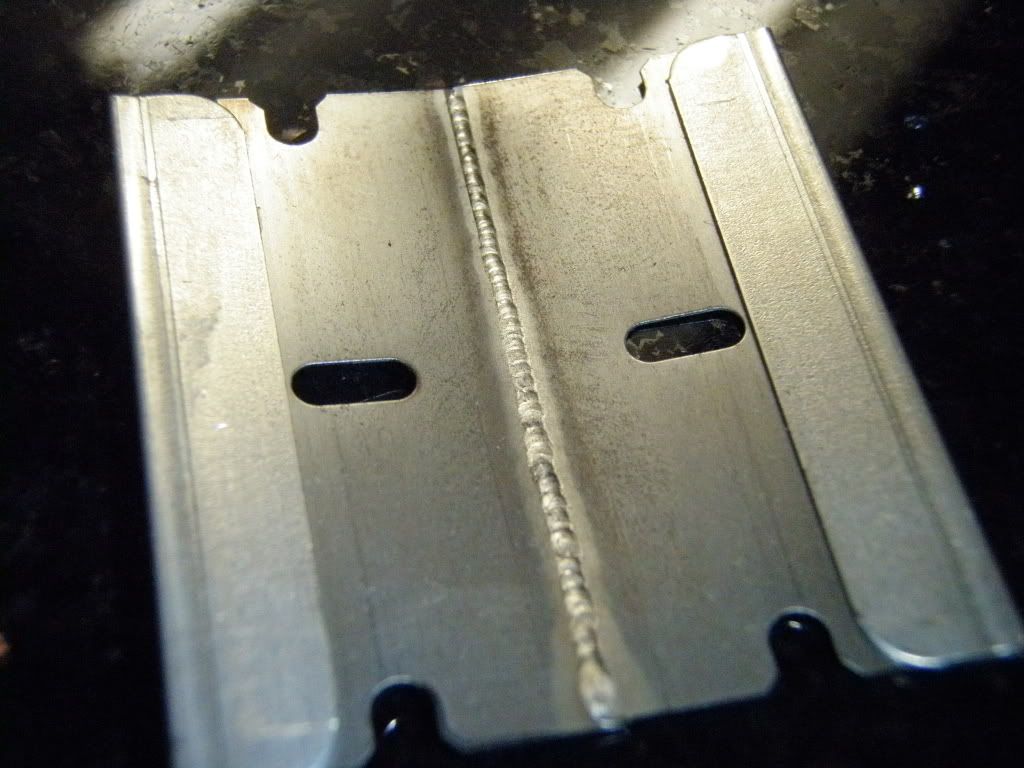

Beautiful welding, wish I could come close to that quality. What are the plans for the seal weld where the tube meets the inside of the bottom.

Thank you for the kind words Kladue. I will purge the welds of course but, I plan to weld the inlet to the bottom before it gets welded to the kettle. This way I can weld the inside 100% without any question. I do plan on welding the outside as much as I can. On the very bottom it gets real tight up near the skirt weld. I am going to hang the tungsten out real far to get up as close as I can. We'll see how I do.......

So just remember all you DIY weldors out there.....its not the machine that makes the weldor. Prost everyone.

So just remember all you DIY weldors out there.....its not the machine that makes the weldor. Prost everyone.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)