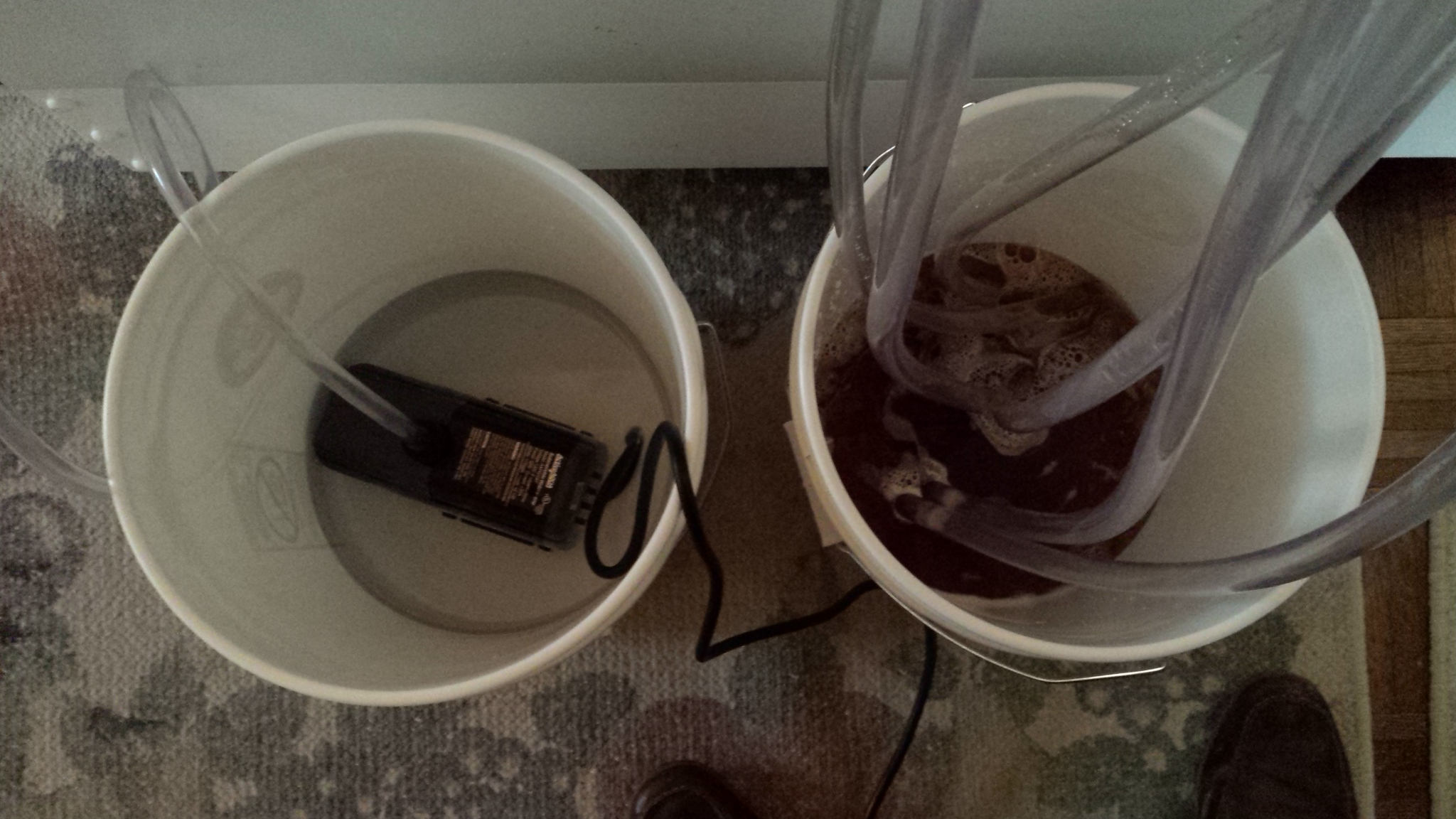

As I've progressed along this long road of brewing obsession, the one thing that I've learned (besides PATIENCE!!!) is that keeping the equipment clean is one of the most important aspects of a brewday. As many of us have, back in the day I didn't pay attention to cleaning well, just wanted to get the brewday over with so I could enjoy the fruits of my labors. And wound up, a few days later, with a VERY stinky brewery/garage, and too much hard work to get it clean enough for the next brewday. I've since learned to clean as I go, so at the end of a brewday my equipment is sparkling clean and ready for the next go-round. Took me a year or two to get it down pat, but now I've got the system down to where I'm done after 5.5-6 hours, with everything clean and ready to go, not to mention a nice brew in the ferment fridge. I do all grain on a 3-vessel propane system, using a plate chiller to get the wort to pitching temperature, and have a nice ferment fridge to keep it where I need it. I MIAB, once the grain is cooled enough to dump/save that gets done, bag gets shaken out then rinsed (if you're considering this route, shaking out BEFORE rinsing will save you a lot of cleaning time, although you may get snarky comments from your SO about grain bits in your hair. I do, every time I brew.). Mash tun gets dumped and rinsed out while the wort is heating up. I've also learned to keep enough hottish water in the HLT at the end of the brewday so I can run it through my hoses/pump, to get them clean; and backflush the chiller after the wort is in the fermenter to have it ready for the next brewday, and store it upside-down so all the water drains out and it's dry and clean for the next brewday.

So, what's your process to clean up the brewery after a long hard slog? Leave it for another day, or clean as you go? We all have different systems, so I thought it would be interesting to see how we all keep the brewery clean for the inevitable next brewday.

So, what's your process to clean up the brewery after a long hard slog? Leave it for another day, or clean as you go? We all have different systems, so I thought it would be interesting to see how we all keep the brewery clean for the inevitable next brewday.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)