That is odd, but I did see something similar in my small scale mashing experiments.

On the other hand, in my actual beer batches I can get to 100% conversion, i.e. realize the full grain potential in mashing. I have also been able to do that in small scale mashes that I recently did for pH experiments.

Kai

That is interesting Kai.

How are you defining the max PPG for your grains?

For those that I could get data specs from the malting companies, like Briess 2row, Crystal 10, 40 and 120L that I'm using on this experiment, I using the following formula to calculate the max PPG's:

PPG=46.214*(DBCG%/100-MC%/100-0.002)

Where

DBCG%=Dry Basis Coarse Grind

MC%=Moisture content

For these malts, this is what I got from Briess:

2Row: DBCG=75%, MC=4%, PPG(Calculated)=35

C10: DBCG=75%, MC=7%, PPG=31

C40: DBCG=73%, MC=5.5%, PPG=31

C120: DBCG=70%, MC=3%, PPG=31

So my low efficiency or extraction may be related to the max PPG I'm using.

I would like to address this issue also, although the PPG/extraction is not the main focus of this experiment but the attenuation or fermentability of crystal malt.

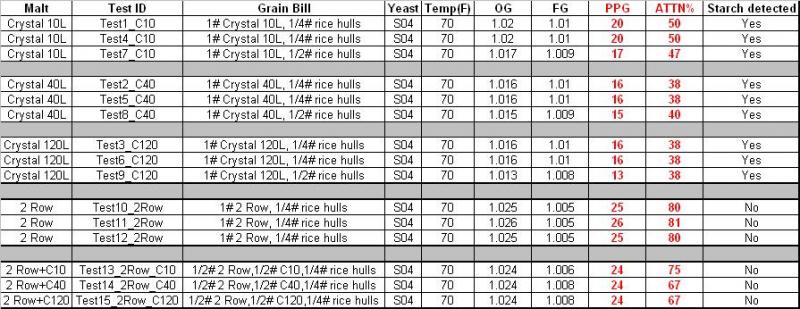

Anyways, I have just started another test batch, now using 50% 2row and 50% crystal malt. 1/4lb of rice hulls was also added to the grain bill. All mashed at 155F.

Got everything done, now fermenting at 70F.

Since I used 1/2# of each malt, the expected OG for this new test would be:

2R+C10 = PPG 2row/2 + PPG C10/2 = 25/2 + 20/2 = 22.5

2R+C40 = 25/2 + 16/2 = 20.5

2R+C120= 25/2 + 16.2 = 20.5

Now, this is what I got, for all three batches OG=1.024.

That makes sense from one side, showing that the new OG is higher than the combination of each malt since the starches from the crystal malts is now converted to sugars by the enzymes from the 2Row malt. That was confirmed with a iodine test. Interesting though is the fact that all three batches came at same OG.

Will post the attenuation results once fermentation is completed.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)