HI_SALENITY

Well-Known Member

I do have a 30 psi regulator is this my problem?

If so what regulator do you recommend ?

If so what regulator do you recommend ?

I have gathered some people drill them out , can you give me a bit size to start with?

There is an internal pressure regulator in each valve, I hope you have the stronger spring installed for propane pressure. You can adjust the flame level with a screwdriver after you remove cap, open any down stream valve wide open and then tune for maximum fire you want and replace cover on valve.

Are the gas fitting jets drilled to 3/32", maximum size would be 7/64" if 3/32" does not give enough flame.

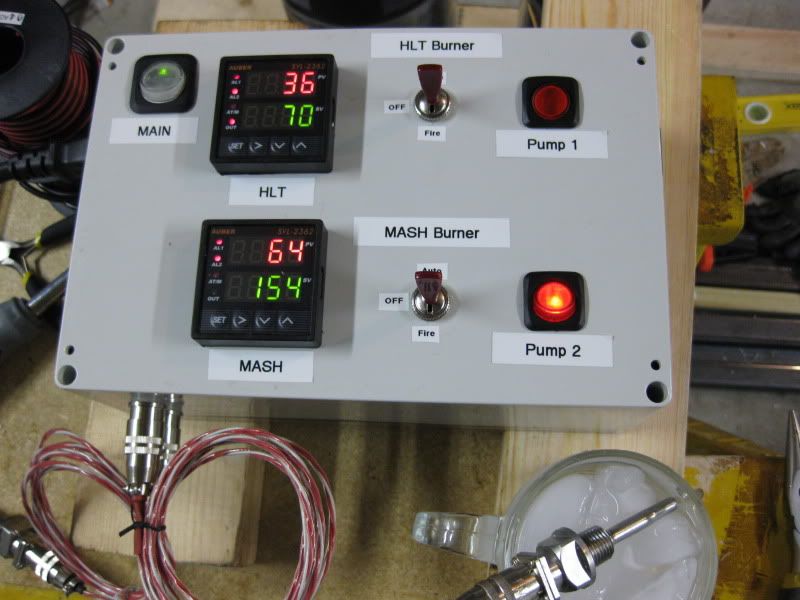

Just a followup.. I got the HOA switches wired in and everything is working great. The center "Off" position kills the solenoid valve power, the top "Auto" position allows the PID to control the solenoid valve, and the bottom "Fire" position sends power directly to the solenoid valve to open (ignoring the PID).

Here's the control panel:

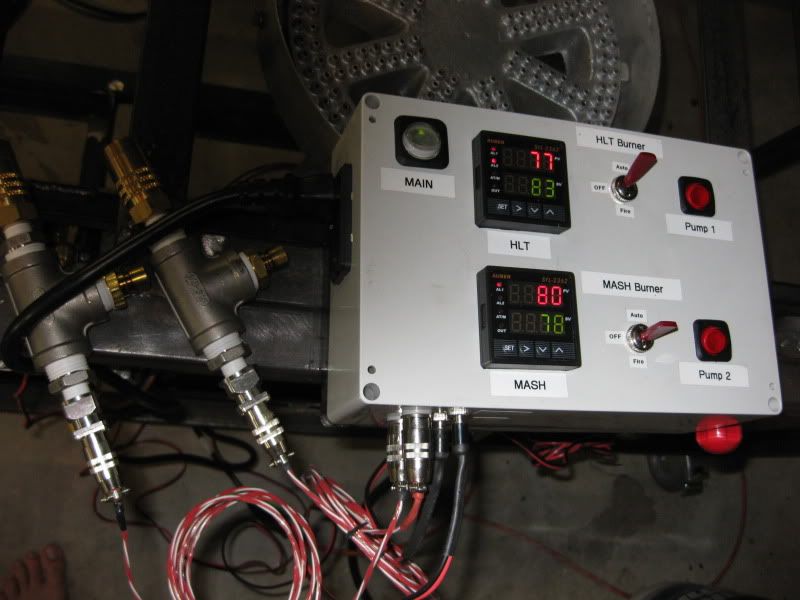

Testing with the RTD tees (Lonnie Mac style):

The RTD inputs and valve power outputs (24V):

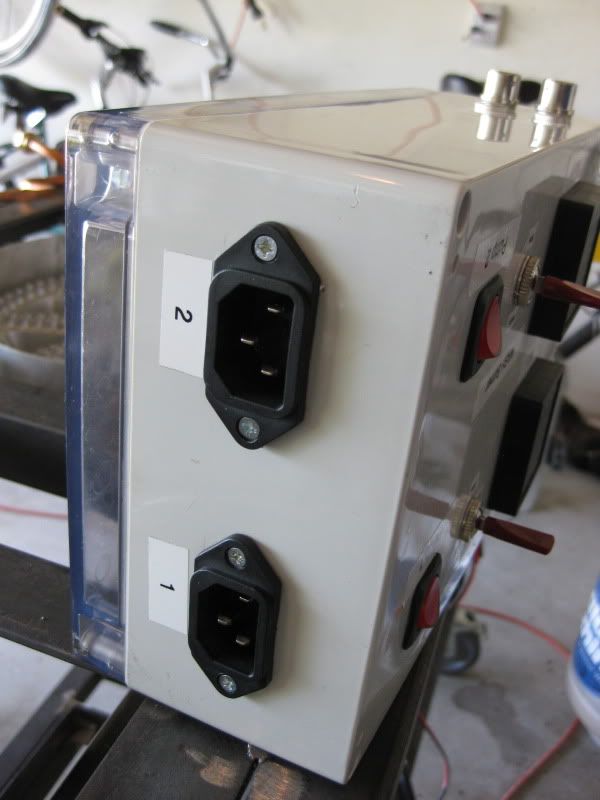

Power in:

Pump power out without the covers (I'm planning to swap these out with the female version anyway, for safety's sake):

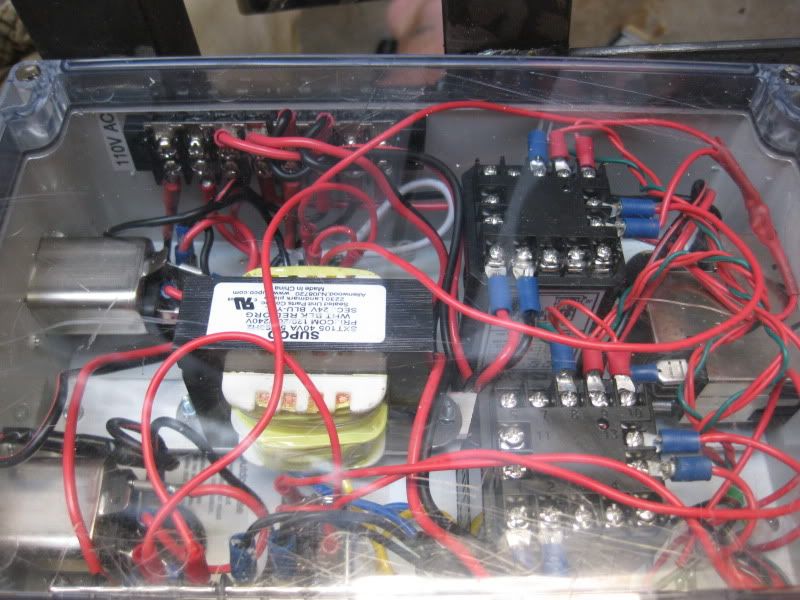

The control panel wiring. The box I used has a clear back, so this is looking in the back of it:

From left to right:

- 2 x output power modules 110V (pumps)

- 110V Terminating block (top)

- 110V to 24V Transformer, 40VA (middle)

- 24V Terminating block (bottom)

- 2 x SYL-2362 PIDs from Auber (in on/off mode)

- Input power module 110V (fused).

- The HOA switches are on either side of the transformer.

--

Josh

I like the power modules. Where did you get those from? I have a similar build. Nice job!

Anyone want to walk me through the temperature calibration for these controllers ? I can't find my instructions.

Hmm... they should be calibrated already. Are you sure your RTD connections are ok?

The instruction manual is here:

http://auberins.com/images/Manual/SYL-2362%20instruction%201.6.pdf

--

Josh

Hmm... they should be calibrated already. Are you sure your RTD connections are ok?

The instruction manual is here:

http://auberins.com/images/Manual/SYL-2362%20instruction%201.6.pdf

--

Josh

How do you have yours programmed? Do you do the Autotune and let the valves cycle on and off to keep it at the set value (SV) or do you have the control mode set to on/off control (At = 0) and let the temp drop below a certain number of degrees (SV-Hy setting) and then kick on the valve and shut off when it reaches a certain temp above the set value (SV+Hy)? I have the same Honeywell valves and worry about them getting killed by continuously cycling on and off in the Auto mode (At=3).

I'm sorry I don't know what the "At" parameter is that you mentioned.

I do have OutY set to 4 which uses J2 as On/off control relay contactor output. I have the Hysteresis set for 2 degrees.

The auto-tune feature is interesting, now that I look at it, but I can see your concern with wearing out the honeywells in PID mode (Outy=2). I'd be curious to see what PID parameter values (P, i, d, SouF, ot) the auto-tune comes up with for this application (mashing, for example). If it seemed like a tolerable pulse frequency for the honeywells, I might switch to that method actually.

--

Josh

Anyone want to walk me through the temperature calibration for these controllers ? I can't find my instructions.

There is no calibration per se. You can make adjustmenys to the PID parameters. Is that what you mean?

Thanks Kladue. So one other question, Should I get a PID with an SSR or a relay? I assume a relay since I do not need rapid/constant switching. IE. electric rims tube.

Do you have a diagram for this setup?

Sawdust,

I was looking at this post where you drew a schematic for another member:

https://www.homebrewtalk.com/f51/wiring-auber-pids-brutus-build-123326

It looks like just the solenoid valve is run by the PID. Could I run the output of terminal 5 to a distribution block and from there run one line to the March pump and the other to a 24v transformer? This way (I assume) you can kick on the pump and the burner at the same time. Or is it recommended to run the pump continuously?

Awesome, so do you continually run your pump?

Sawdust, why did you go with the RIMS tube and not a direct fired system? Just wondering what the advantages of one method vs the other is. I originally was going with a RIMS tube but then decided to go down this path with the automated burners. I'm sure I'll get this thing running then want to switch again.

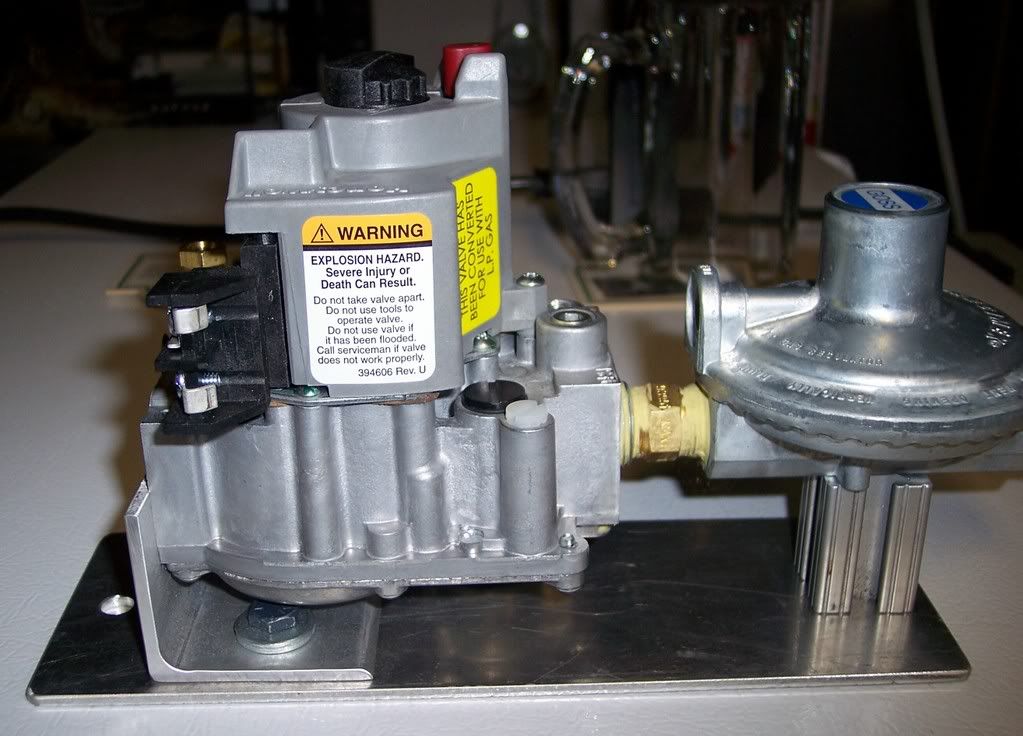

So, do you need a Honeywell ignition unit, i.e., P/N S8610U to make the VR8200 work or is a PID all that's necessary?