KyleWolf

Well-Known Member

Hi everyone.

I have been reading a lot of the threads people have posted for their motorized mills. I see a lot either use something to stabilize a drill or get a 1/6-1hp motor. The motors are a bit pricey for my tastes, and currently I just grab my drill and away I do, but I would like to make things a little more "hands-off"

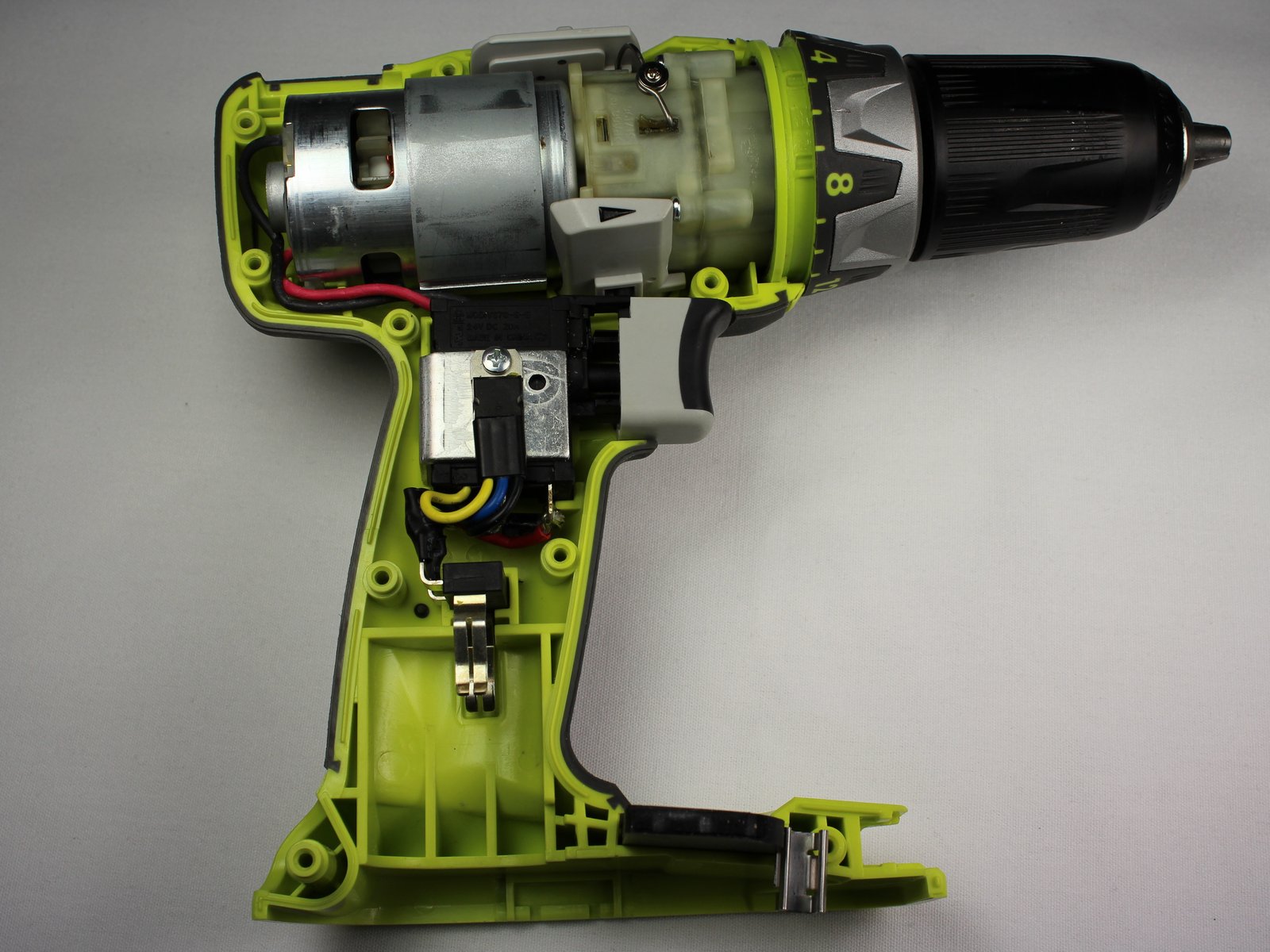

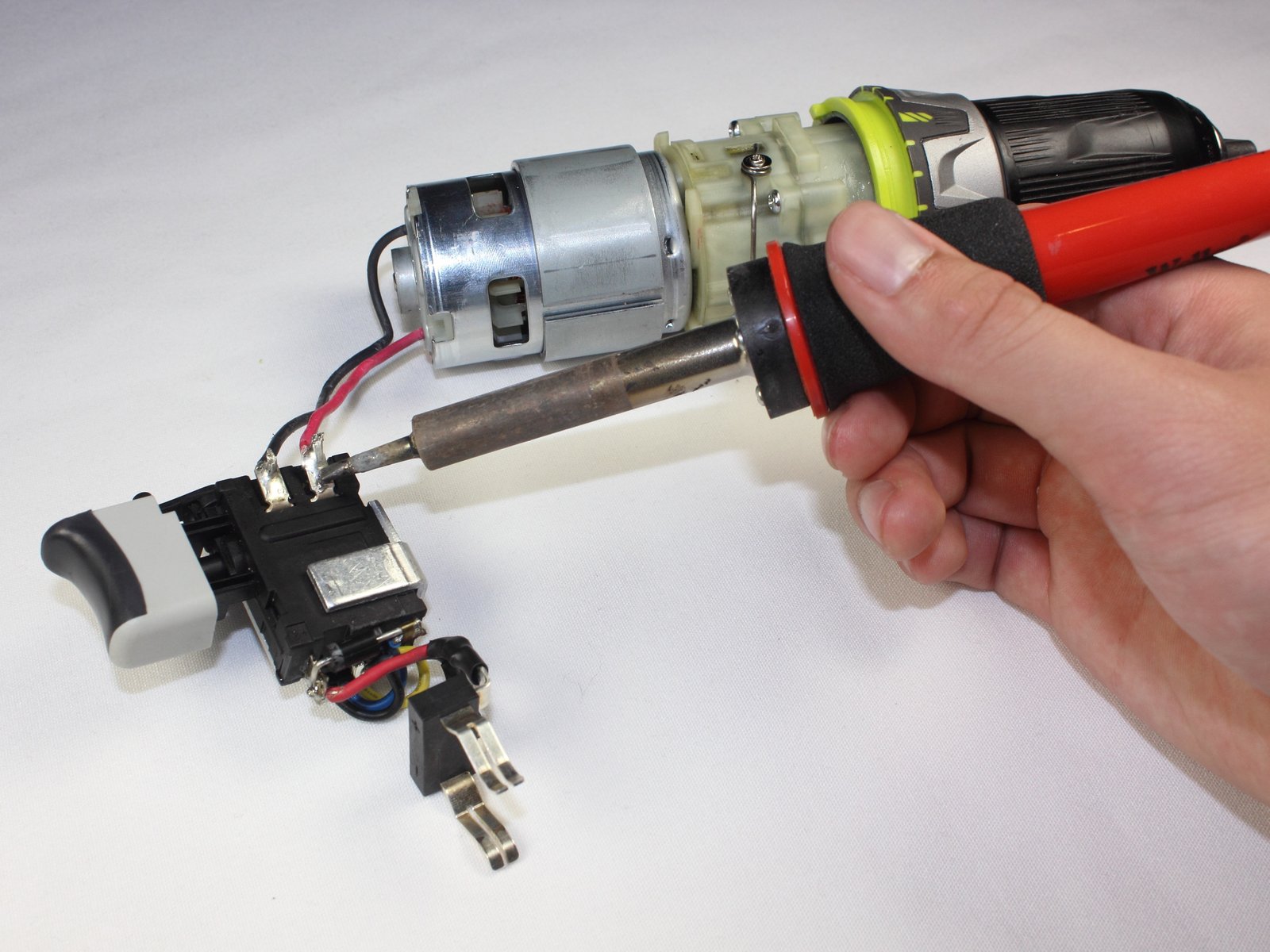

I was wondering if anyone has tinkered with taking a drill apart, mounting the motor and chuck alone, and then using a power control knob (like you would when making a stir plate) for managing output. So basically, removing the casing and mounting just the motor inside. kind of like what is seen below.

Any ideas or thoughts. I am interested to know what people think of the idea.

Thanks

I have been reading a lot of the threads people have posted for their motorized mills. I see a lot either use something to stabilize a drill or get a 1/6-1hp motor. The motors are a bit pricey for my tastes, and currently I just grab my drill and away I do, but I would like to make things a little more "hands-off"

I was wondering if anyone has tinkered with taking a drill apart, mounting the motor and chuck alone, and then using a power control knob (like you would when making a stir plate) for managing output. So basically, removing the casing and mounting just the motor inside. kind of like what is seen below.

Any ideas or thoughts. I am interested to know what people think of the idea.

Thanks

Last edited: