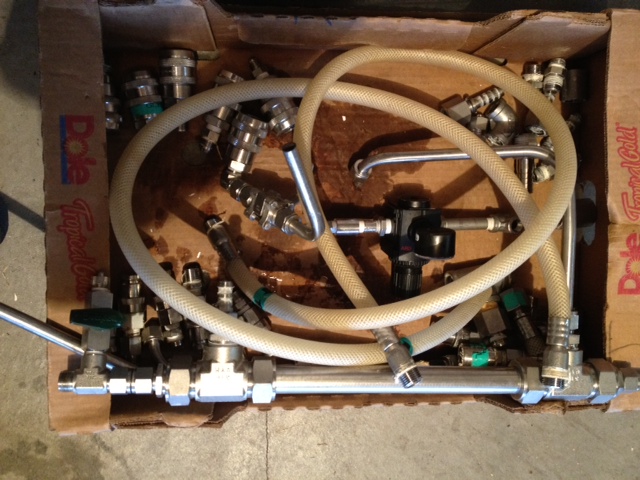

A buddy sent me a link to a craigslist ad and before I new it we both had 16 gallon conicals in our garage, each conical has a 110v pump, stand and a box full of oversized stainless quick disconnects, fittings, an oxygen regulator, a homemade heat exchanger of some kind, and both conicals were fitted with a stainless coil inside. Not a bad score for $150.

They looked a bit more used than I was hoping for but I figured if I couldn't get the holes on top sealed up and cleaned up then i'd sell off the extra fittings and conical and get a new one to put in the stand.

Now to build a chamber to house it so I can keep the temp controlled!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)