HopsAreGood

Well-Known Member

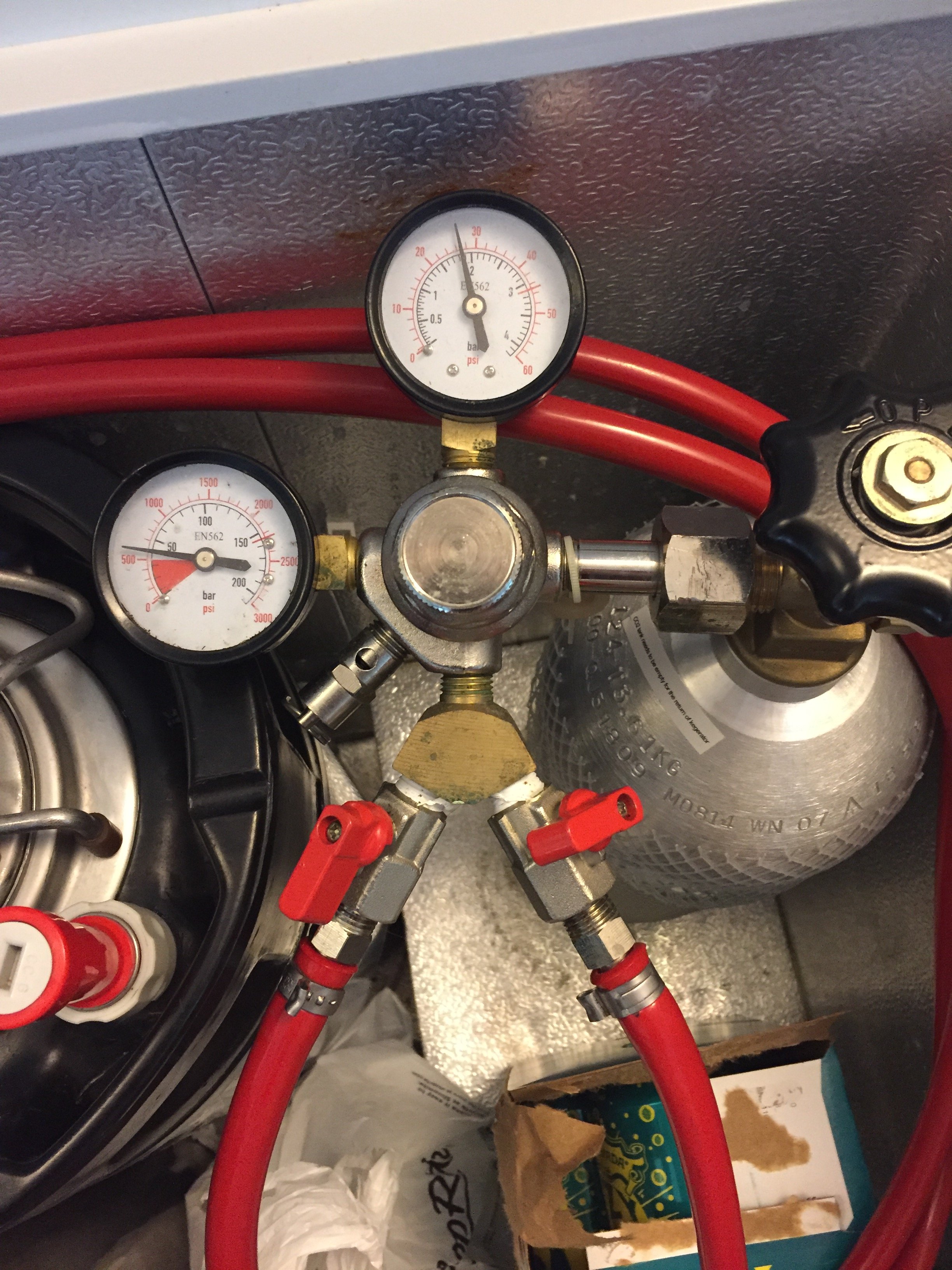

I would say 90% of the time that I turn the dial on my CO2 regulator, the little bar in the gauge goes up very smoothly. But every so often when I turn it up it’ll be kind of sticky. I’ll turn the dial and I’ll hear the CO2 coming in, but then it will jump from say 8 to 14 and then stick, and then it might jump from something like 14 to 20 etc. ... It’s been like this for as long as I can remember and hasn’t really impacted anything in any big way other than being a minor annoyance, but I figured I’d ask to see why this may be happening. Thanks in advance.