Sorry I didn't mean to sound frustrated at anyone, just myself

I may try changing my probe location again.

I will have to recheck my probe accuracy. Last time I checked it was fine

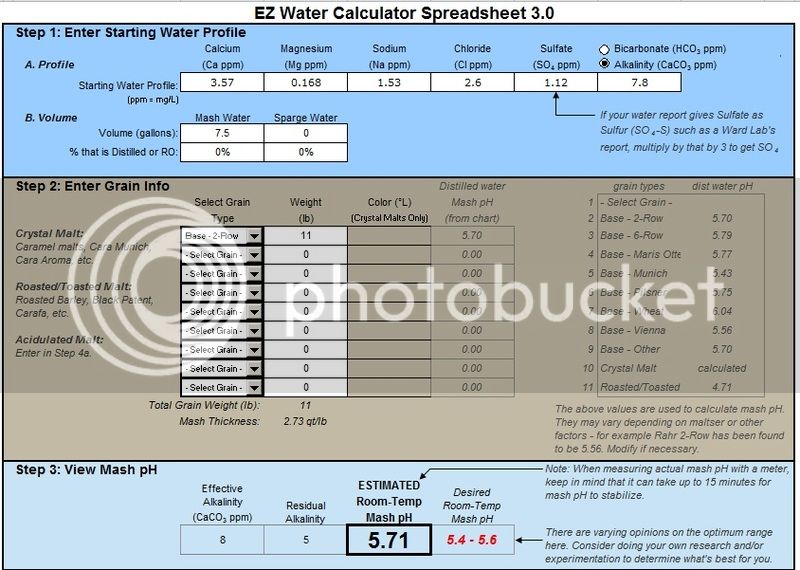

I am investigating pH meters to test my mash pH. I didn't know single malt single hops needed an acidic adjustment so that may be another culprit...

Nice setup. I have a 3 full vessel E-brewing setup. Last weekend I did a BIAB in my old 28qt turkey fryer brew kettle. After 40-50 batches, this was my first time at full BIAB and I was a little disappointed. I am use to 80-90% with my HLT, MASH Kettle, Boil Kettle, RIMS setup. I feel your pain. My efficiency was only around 65%. It was an experiment as I did it using my controller with a stand-alone, glass top, drop in stove on a metal step stool. the stove has an oversized burner that is as big as my kettle and got all 6 gallons boiling pretty well. I used an adapter cord that would plug into my controller panel and controlled the whole stove. It worked great. and cleanup was so much easier. RDWHAHB.

I think your efficiencies could be affected by a lot of things. I am not sure re-circulation matters a lot for efficiency in BIAB, as long as your element keeps the temp correct. Although it might keep the temps consistent throughout the grain, you can always stir it. I see your kettle has a welded port above the valve. Can you get a probe or thermometer for there as a double check or put in a thermal-well?

As mentioned by a couple others, the first thing I thought of was that your probes might need adjustment/compensating. Have you calculated your probe variance? This is the difference between what the probe puts out and the actual reading. You set this by putting the probe in boiling water and see what the temp it measures is. Boiling water is achieved at 212 degrees at Sea level. It will not get hotter that that unless it is under pressure. I think boiling temp goes down 1 degree for every 1000 feet above sea level you are (Google this to make sure). I do this on all my probes and label them with it. You do have to remember to set the PID for the probe you are using.

On your My-Pin PID you can hold the "Set" button for 4-5 seconds and it will go into its setup mode. Click the "Set" button click through the settings. The button next to it changes the digit you are setting and the Up/Down arrows change the setting (you already know this because it is just like when you are setting the temp). Press "Set" again to set it and Hold "Set" for 4-5 seconds to exit the settings (or wait 30 seconds).

When in the settings mode, keep clicking the set button until you see P-V, I think (P-?). It will be 5 or 6 clicks in. You can use this setting to compensate for probe variances. If your probe measures 10 degrees high you would set it to 10. If your probe measures 10 degrees low you set it at -10. As I mentioned above, check all of your probes. The settings will be different for every probe.

As you said, you may also want to look at your water chemistry. I would go ahead and get a PH meter and/or some test strips. You can get a cheap meter on e-bay for $8 shipped. I try to mash at around 5.0-5.2.

I think your mill setting at .039 is probably OK. If you have some feeler gauges you can check to make sure it is right. If not, go to an auto parts store and pick some up. I have heard of people using anywhere from .032 - .040 and claiming that they are happy with it and getting good efficiencies. Some people say .035 is good for BIAB. I think my corona mill is at .035 (I have an 8mm bolt with a socket/power drill adapter I use to save my shoulder).

One last thing. Some people mentioned boil off and not wanting to lose wort. You are actually loosing steam and chemicals. I saw a BeerSmith youtube with Randy Mosher (I think), where he said that you really need a good rolling boil to get out all of the chemicals you don't want. Anything less is not good enough. You can always add water back into the boil at the end to reach a volume.

Keep us updated. Cheers!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)