Firewalker11

Brewer

Gotcha, thanks for answering my silly questions.

One thing I would like to try and wonder if anyone else has tried is having a battery backup/clock so if there is a power cut the STC knows where it is up to (or are you gona tell me it already does that

Thanks for all your hard work on the STC, Alphaomega, I have my mini all programmed up and waiting for my STCs to arrive so I can program them. I want to leave the header pins and the mini connected so I can upload profiles as and when needed.

One thing I would like to try and wonder if anyone else has tried is having a battery backup/clock so if there is a power cut the STC knows where it is up to (or are you gona tell me it already does that).

Either a board that can piggyback to the stc on the right pins, maybe a 9v battery that monitors the 5v line and if it drops below kicks in?

We get the odd short power dropout occasionally in winter so could be a bummer if you have to reprogram from a few days in etc or don't know it's gone out.

Anyway I just had to say thanks for a fantastic project.

Do you think if I try and track the correct pins, this would accept the code if I put header pins on it?

You didn't have to beat around the bush, a simple 0 would have been more efficient.

I'll just have to wait on the slow boat from China. - Thanks

Thanks for the offer, I think I may have contacted you recently(Via a website selling flashed units, unless I am mistaken?), I am in New Zealand and we have 230v so I don't think it was an option.I can have a controller to you this week if in a hurry I have them in stock in Michigan

Thanks for the offer, I think I may have contacted you recently(Via a website selling flashed units, unless I am mistaken?), I am in New Zealand and we have 230v so I don't think it was an option.

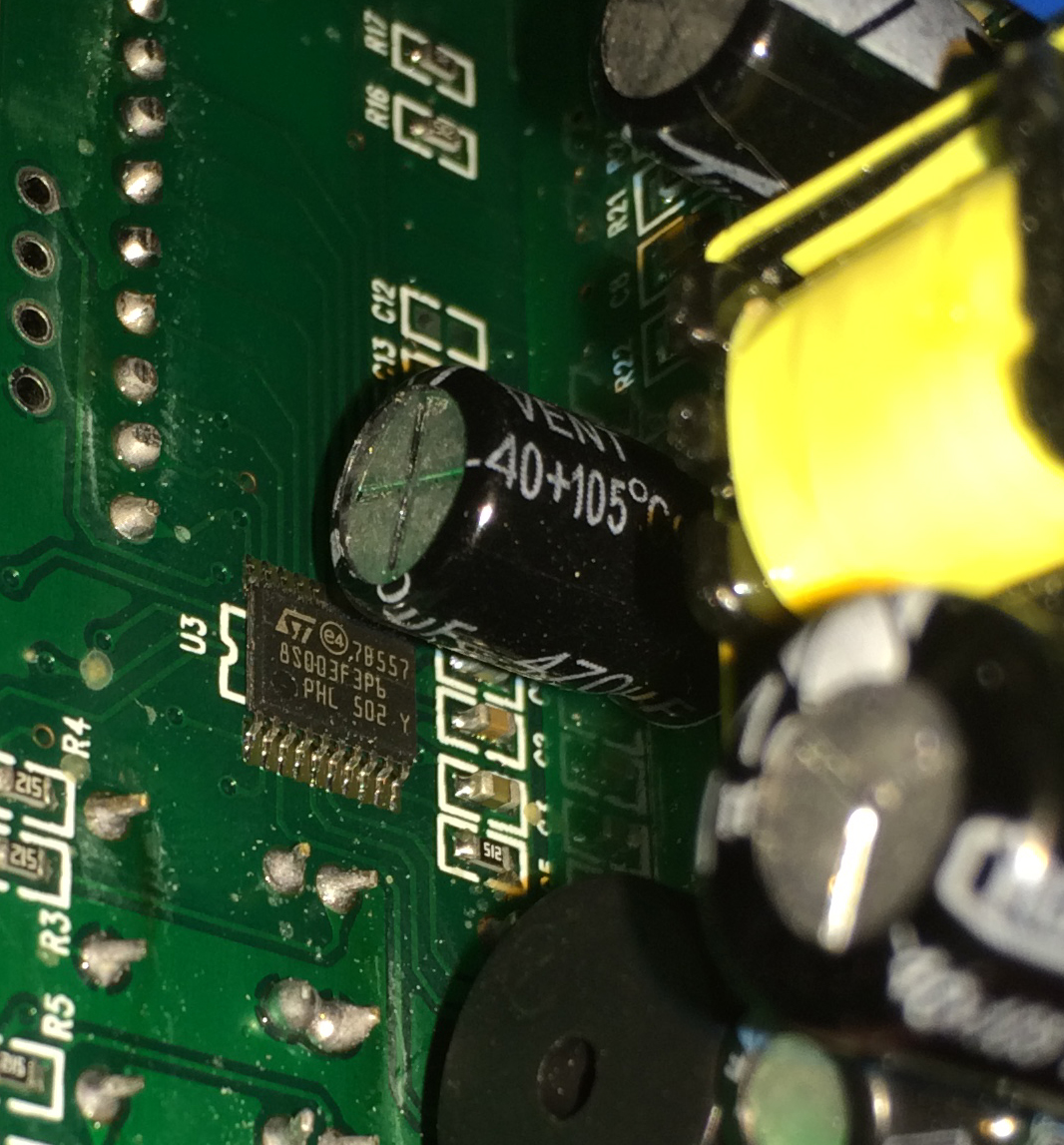

Interestingly the unit in the photo above is an STC1000 that is 110-240v, so hopefully they make the flashable unit in the 230/40 volt flavor.

Nice looking unit you have, by the way. I hope to 3d print my housing for it.

I ordered an Inkbird controller thats in F, and then I stumbled upon doing this flashing. Well it turns out that the board from Inkbird isnt compatible.. or at least the one I got.

I have 2 more and one of them was compatible so at least I will have one controller that can ramp and be programmed.

I hate to be a pain but does anybody have a lager profile ready for the 1000+?

Tried searching for the directions on how to make the Pro Mini for flashing these. Can't seem to find it. A little help here.

I can build you one if you don't already have parts, but here are the directions from alpha

https://github.com/matsstaff/stc1000p/tree/master/usermanual

Couple questions, what do you have your hy set to and what was it reading for temp vs the current sp? I don't think I've seen repeated blinking then not operating, then blinking again as you have stated. I think once the hy has been exceeded, it is supposed to cool/heat until it reaches the current sp, even if it skips back within range before the delay timer runs out. I guess if it is keeping your temps pretty close, I wouldn't worry too much. I have my hy set to .3, don't recall what the delay is set to, maybe a few minutes? I am using a glycol jacket and heat wrap. I haven't set the delay down lower even though I could with my setup because I am trying to cancel out any ping pong effect, but I'm not sure it makes much difference in my situation.

I'll have to watch it closely tonight. Since I have a pump for cooling and heat tape for heating I'm going to set both delays to 0. And look at hy....example....temperature is greater than setpoint + hysteresis AND the time passed since last cooling cycle is greater than cooling delay, then cooling relay will be engaged.