Used kviek in a neipa and today day 7 took a fg reading its 1.028. OG was 1.077. Any way I can get this down? I have some alpha amylase on hand or I could add a pack of rehydrated us-04 trying to keep in the neipa style. Gravity sample was basically a sweet malt bomb with hardly any hop presence, my dry hops just wanna drop right through the solution. Wonder if that has anything to do with the high fg. I mashed at 153 for 90 min and the grain bill was 70% GP/2 row, with wheat and oats. It’s undrinkable at this point so I need help to get his down to atleast 1.016.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stalled ferm high fg

- Thread starter olotti

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I would give it time. I've had some big beers where the final few points took another week or so. I usually take a gravity reading at the 7-10 day Mark, wait 3 days and check again. If it hasn't moved at all I'll give it a few more days and check again before packaging. Sometimes on that final check I've had it drop.

sharknado2

Member

- Joined

- Jun 29, 2018

- Messages

- 16

- Reaction score

- 9

1.028 is not a bad FG if you started at 1.077. As I understand kviek yeast is a fast fermenter so I wouldn't spect it to go any further down.

I would just wait and taste it.

I would just wait and taste it.

olotti

Well-Known Member

Kviek should go past that. That’s 77% attenuation which is in the 75-85% attenuation possibility but man that seems high. I added some amylase and a pack of 05 to get it moving.1.028 is not a bad FG if you started at 1.077. As I understand kviek yeast is a fast fermenter so I wouldn't spect it to go any further down.

I would just wait and taste it.

My math shows less than 64% attenuation, which is low. Letting it go longer is unlikely to get it where you want it, neither is adding more yeast. The food that’s left is most likely inedible, rather than just yeast on strike.

olotti

Well-Known Member

See that’s worse than I thought. And again I’m just baffled as to why this would happen in the first place. Maybe it was just a bad batch Of yeast. I did add some amylase enzyme and a pack of 05 and it’s kicked off againMy math shows less than 64% attenuation, which is low. Letting it go longer is unlikely to get it where you want it, neither is adding more yeast. The food that’s left is most likely inedible, rather than just yeast on strike.

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

bracconiere

Jolly Alcoholic - In Remembrance 2023

as i said in the other thread. being that it's not too late. if you really want it to go down, i'd toss 0.5 gram or 1 gram of gluco in. kinda incrementally reducing the FG until target met? worth a shot anyway, lol

olotti

Well-Known Member

See my reply above yours.as i said in the other thread. being that it's not too late. if you really want it to go down, i'd toss 0.5 gram or 1 gram of gluco in. kinda incrementally reducing the FG until target met? worth a shot anyway, lol

bracconiere

Jolly Alcoholic - In Remembrance 2023

See my reply above yours.

sorry, well you said fermented in the 90's, maybe active fermentation got up over the kill temp for yeast? and the pack of 05 picked up a bit? i think yeast die at 104f or something don't they? so 90's is close and with a vigorus ferment?

olotti

Well-Known Member

I’ve read not to mess with gluco cuz it just ferments all the way down. I have alpha enzyme in hand and it’s worked for me in the past on a big stout that stalled. If I can get it to drop 10pts I’ll be happy.as i said in the other thread. being that it's not too late. if you really want it to go down, i'd toss 0.5 gram or 1 gram of gluco in. kinda incrementally reducing the FG until target met? worth a shot anyway, lol

olotti

Well-Known Member

That’s possible. My temp reading is me pulling a sample and putting my thermometer in it, actual internal temp during vigorous fermentation may be higher. But I’ve read that kviek likes it warm like even into low 100’s. I believe on the pack it says temp range of 75-95 I think.sorry, well you said fermented in the 90's, maybe active fermentation got up over the kill temp for yeast? and the pack of 05 picked up a bit? i think yeast die at 104f or something don't they? so 90's is close and with a vigorus ferment?

bracconiere

Jolly Alcoholic - In Remembrance 2023

gluco has a time limit though, like all enzymes it only works for a while.

not sure but my limited google search for something, this is as close as i got

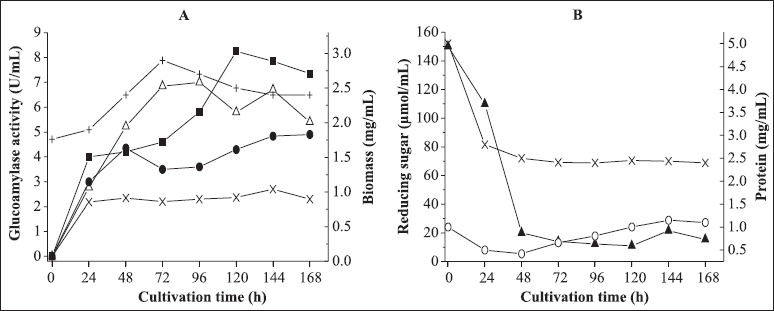

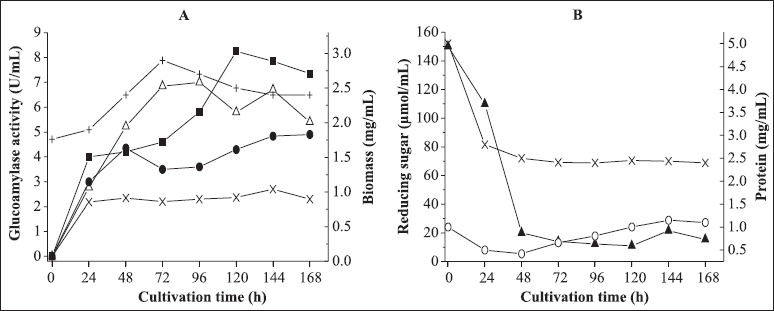

GA production by yeast S. cerevisiae in medium with different starches. (A)Soluble starch –Δ; Cassava starch –●; Potato starch –■; Corn starch –x, and biomass in soluble starch –+ (For cellular mass determination, its was dried at 60°C until constant weight); (B) pH variation in the cultivation medium –x, protein concentration –○; and reducing sugar –▲ (values were determined using soluble starch as substrate).

not sure but my limited google search for something, this is as close as i got

GA production by yeast S. cerevisiae in medium with different starches. (A)Soluble starch –Δ; Cassava starch –●; Potato starch –■; Corn starch –x, and biomass in soluble starch –+ (For cellular mass determination, its was dried at 60°C until constant weight); (B) pH variation in the cultivation medium –x, protein concentration –○; and reducing sugar –▲ (values were determined using soluble starch as substrate).

bracconiere

Jolly Alcoholic - In Remembrance 2023

https://www.finecooking.com/article/the-science-of-baking-with-yeast-2

i guess the terminal point for ALL yeast is 138f....

i guess the terminal point for ALL yeast is 138f....

olotti

Well-Known Member

Well it’s a baffling set of circumstances. The answer is in there somewhere and I’ve posted the scenario on a fb home brewers page and here and theories abound but it’s hard to just pinpoint one reason. I used the same process, grainbill, ferm method as I always have including two beers made just weeks before also using kviek that had no problems, they didn’t hit 80% attenuation but that was my fault for mashing you high for a big beer, 154 for 1.083 OG.https://www.finecooking.com/article/the-science-of-baking-with-yeast-2

i guess the terminal point for ALL yeast is 138f....

I would have recommended yeast nutrient and warming the fermenter if it was below the yeast's ideal temperature. I've had issues with Omega Voss stalling, and I'm convinced that it's a combination of low fermentation temperatures and inadequate nutrients. Some will argue that yeast nutrient is not a necessity, but there's some evidence that shows some of these kveik strains to have issues with low nutrient worts.

I just brewed today and did two things differently that I haven't done in the past: 1) I step mashed starting at 143 then worked up to 152 and finally 158 before mashing out and 2) added double the yeast nutrient that I normally would. I'm interested to see if I can get my Voss to finish out this time without stalling. This time, I've also got an Inkbird with a seedling mat, so that will help keep the ferm temps up.

I just brewed today and did two things differently that I haven't done in the past: 1) I step mashed starting at 143 then worked up to 152 and finally 158 before mashing out and 2) added double the yeast nutrient that I normally would. I'm interested to see if I can get my Voss to finish out this time without stalling. This time, I've also got an Inkbird with a seedling mat, so that will help keep the ferm temps up.

olotti

Well-Known Member

Do me a favor. Let me know how this goes. I already use a seedling mat just for this yeast, it works great. I get my beer to sustain in the 90’s during fermentation with kviek. I as well have also read and people recommended that yeast nutrient is a must with kviek because it ferments so warm and so fast so I’m gonna do that next time. How much nutrient did u use this time?I would have recommended yeast nutrient and warming the fermenter if it was below the yeast's ideal temperature. I've had issues with Omega Voss stalling, and I'm convinced that it's a combination of low fermentation temperatures and inadequate nutrients. Some will argue that yeast nutrient is not a necessity, but there's some evidence that shows some of these kveik strains to have issues with low nutrient worts.

I just brewed today and did two things differently that I haven't done in the past: 1) I step mashed starting at 143 then worked up to 152 and finally 158 before mashing out and 2) added double the yeast nutrient that I normally would. I'm interested to see if I can get my Voss to finish out this time without stalling. This time, I've also got an Inkbird with a seedling mat, so that will help keep the ferm temps up.

Do me a favor. Let me know how this goes. I already use a seedling mat just for this yeast, it works great. I get my beer to sustain in the 90’s during fermentation with kviek. I as well have also read and people recommended that yeast nutrient is a must with kviek because it ferments so warm and so fast so I’m gonna do that next time. How much nutrient did u use this time?

I always use the Wyeast beer nutrient as specified which is 1/2 tsp per 5-gallon batch. This time, I used an entire teaspoon plus the flakes left in the container. I figure you can't have too much yeast nutrient (within reason, of course). Here's a link to a post within a thread I started with the same issue: Sluggish Finish for Omega Voss

I generally pitch at around 90*, let it stay there for a few days, then let it free fall. What I've found, though, is after about 3 days, the yeast mostly finishes but my fermenter temp will drop into the 60's which seems to be much too cold for these kveik strains. Even beers that I felt 100% comfortable with bottling have ended up on the over-carbonated side by the last few bottles. This tells me that there is still a gravity point or two hanging around and the yeast is finishing the job in the bottles instead of in the fermenter.

I've got the seedling mat wrapped around the carboy with bungee cords and the temp sensor on the opposite side of the fermenter. Right now it's reading about 90* which should be about right. I've got it set to 85*, but might end up dropping it slightly to compensate for the temperature difference between the liquid and the ambient.

Also, I wrap my fermenter in a blanket to keep things nice and toasty. That's always worked well for me regardless of the yeast, but I'm hoping that by preventing the yeast from going dormant too early, they'll finish out better and healthier. Much easier to maintain a healthy fermentation than try to manufacture one after it's too late.

I should also say that I'm using the Lallemond Voss dry packet this time (for the first time) so all of this is pretty much moot.

olotti

Well-Known Member

Yeah I pitch kviek at 90 then put the seedling pad on the carboy secure it with the carboy carrier and wrap a blanket around it. I leave the pad on it for at least 5 days which is when I take my fg reading. Then if I’m happy with it I’ll take the blanket and pad off so it can cool before I add my dry hops. Only kviek I’ve used is omega brand voss and hornidal.I always use the Wyeast beer nutrient as specified which is 1/2 tsp per 5-gallon batch. This time, I used an entire teaspoon plus the flakes left in the container. I figure you can't have too much yeast nutrient (within reason, of course). Here's a link to a post within a thread I started with the same issue: Sluggish Finish for Omega Voss

I generally pitch at around 90*, let it stay there for a few days, then let it free fall. What I've found, though, is after about 3 days, the yeast mostly finishes but my fermenter temp will drop into the 60's which seems to be much too cold for these kveik strains. Even beers that I felt 100% comfortable with bottling have ended up on the over-carbonated side by the last few bottles. This tells me that there is still a gravity point or two hanging around and the yeast is finishing the job in the bottles instead of in the fermenter.

I've got the seedling mat wrapped around the carboy with bungee cords and the temp sensor on the opposite side of the fermenter. Right now it's reading about 90* which should be about right. I've got it set to 85*, but might end up dropping it slightly to compensate for the temperature difference between the liquid and the ambient.

Also, I wrap my fermenter in a blanket to keep things nice and toasty. That's always worked well for me regardless of the yeast, but I'm hoping that by preventing the yeast from going dormant too early, they'll finish out better and healthier. Much easier to maintain a healthy fermentation than try to manufacture one after it's too late.

I should also say that I'm using the Lallemond Voss dry packet this time (for the first time) so all of this is pretty much moot.

Yeah I pitch kviek at 90 then put the seedling pad on the carboy secure it with the carboy carrier and wrap a blanket around it. I leave the pad on it for at least 5 days which is when I take my fg reading. Then if I’m happy with it I’ll take the blanket and pad off so it can cool before I add my dry hops. Only kviek I’ve used is omega brand voss and hornidal.

Sounds like you're doing everything the way I do. Only thing I can suggest would be going back to the yeast nutrient. There's a recent BrewStrong episode where Jamil and Palmer talk about stalled fermentations and what to do to get back on track. They both say that, basically, almost all stalled fermentations are a nutrient issue. It's worth a listen if you have an hour: The Brewing Network Presents | Brew Strong: How to prevent a stuck fermentation on Apple Podcasts

I was in the midst of a stalled fermentation with the Ode to Arthur recipe. I added heat and boiled some nutrient, and it dropped about 3 or 4 gravity points.. Enough for me to be comfortable about bottling it. Still, my last few bottles are fizzier than I wanted.

olotti

Well-Known Member

Ok cool I’ll check out that link.Sounds like you're doing everything the way I do. Only thing I can suggest would be going back to the yeast nutrient. There's a recent BrewStrong episode where Jamil and Palmer talk about stalled fermentations and what to do to get back on track. They both say that, basically, almost all stalled fermentations are a nutrient issue. It's worth a listen if you have an hour: The Brewing Network Presents | Brew Strong: How to prevent a stuck fermentation on Apple Podcasts

I was in the midst of a stalled fermentation with the Ode to Arthur recipe. I added heat and boiled some nutrient, and it dropped about 3 or 4 gravity points.. Enough for me to be comfortable about bottling it. Still, my last few bottles are fizzier than I wanted.

Similar threads

- Replies

- 16

- Views

- 7K

- Replies

- 3

- Views

- 1K

- Replies

- 0

- Views

- 2K

Latest posts

-

-

-

-

Factors affecting Water Chemistry Calculations (Oh no, not again!)

- Latest: BrewnWKopperKat

-

-

-

-