I was thinking about trying a spunding valve. My concern is once I transfer out of the fermenter, I don't have any temperature control. I was thinking, since fermentation is almost complete, perhaps temperature control is no longer needed. Anyone have any thoughts on this?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spunding question

- Thread starter enkamania

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

homebrewfinds

Well-Known Member

- Joined

- May 13, 2019

- Messages

- 157

- Reaction score

- 46

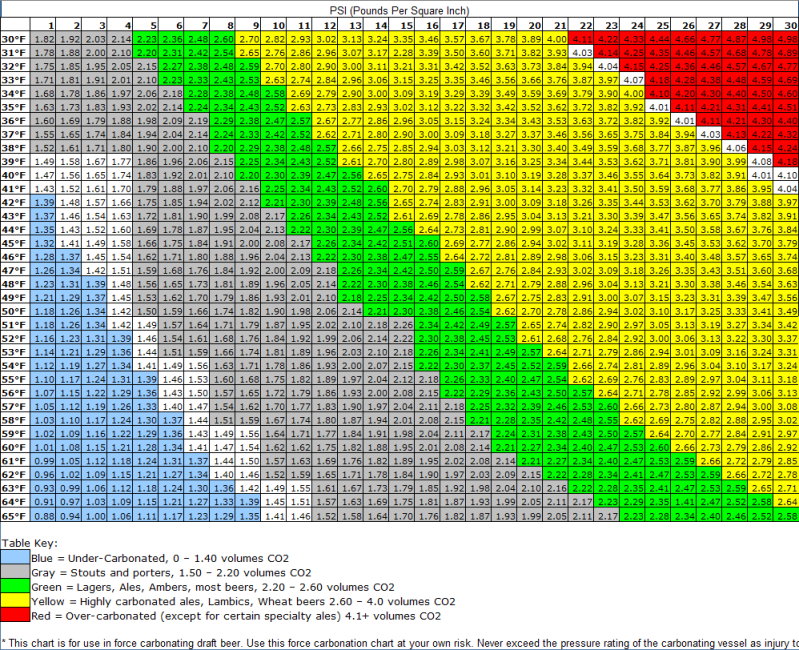

Are you thinking about temperature because you're wanting to naturally carbonate after fermentation? If so, that should be too big of an issue as long as it's a reasonable temperature. You'd just look up the pressure you need based on the temperature using a carbonation chart. I have a couple of posts that would be worth looking at... Spunding Valve Build and Kegland BlowTie Review

I was more worried about off flavors. It would be in my house, so 68-75 degrees. Thanks for the links, I'l check them outAre you thinking about temperature because you're wanting to naturally carbonate after fermentation? If so, that should be too big of an issue as long as it's a reasonable temperature. You'd just look up the pressure you need based on the temperature using a carbonation chart. I have a couple of posts that would be worth looking at... Spunding Valve Build and Kegland BlowTie Review

- Joined

- May 28, 2018

- Messages

- 3,041

- Reaction score

- 2,463

I spund in kegs after closeds transfer from primary. The only temp control I use when spunding is fermwrap heater if the beer is a cool fermented lager and I need to bring up temp for D rest. I do not use any temp control when spunding ales, it owrks fine.

As you noted, fermentation is almost complete, so there is little chance of off flavors being produced, not at the temps you report anyway.

As you noted, fermentation is almost complete, so there is little chance of off flavors being produced, not at the temps you report anyway.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

I spund on the cheap....$10 from Menards.

$4.99 for the regulator.

$3.99 for 0-60 PSI gauge.

The high pressure side is plugged, low pressure side is connected to the keg. The gas vents through the regulator at the set point and rechecks when the pressure drops to the set point.

Super simple works good.

$4.99 for the regulator.

$3.99 for 0-60 PSI gauge.

The high pressure side is plugged, low pressure side is connected to the keg. The gas vents through the regulator at the set point and rechecks when the pressure drops to the set point.

Super simple works good.

Last edited:

Pretty cool, @Schlenkerla. That idea never crossed my mind. I'm going to file this away for when I need something like that.

- Joined

- Feb 19, 2017

- Messages

- 959

- Reaction score

- 1,217

@Schlenkerla Not sure I follow your set up.

1. Gas 3/8" Barb Ball Lock Disconnect

2. hose to the psi gauge

3. where is the regulator?

1. Gas 3/8" Barb Ball Lock Disconnect

2. hose to the psi gauge

3. where is the regulator?

@Schlenkerla Not sure I follow your set up.

1. Gas 3/8" Barb Ball Lock Disconnect

2. hose to the psi gauge

3. where is the regulator?

He's spunding, which means letting the fermentation finish in the keg. Fermentation of course produces CO2, and by allowing that CO2 to stay in the keg, it self-carbonates the beer, much like how bottle conditioning carbonates beer.

The spunding valve allows him to maintain a specific pressure during this time. It releases pressure when it gets higher than he wants.

*****

He has it set at 21psi, which normally would be too high for serving beer. But the beer must be kept at ferm temps, which would be, for example, in the mid 60-degree range.

Let's suppose he's got it at 63 degrees. According to the chart below, 21 psi at 63 degrees will give him 2.16 volumes of CO2 in his beer. When it's done fermenting, if he lowers the temp of the finished beer to, say, 40 degrees, the beer, being colder, will absorb CO2 more readily. That will drop the pressure to between 8 and 9 psi.

You can see this in the chart by looking across the 40-degree line until you find 2.16 volumes of CO2, and reading the associated pressure above. There's no "2.16" but it's between 2.10 and 2.20 volumes.

Last edited:

@Schlenkerla Not sure I follow your set up.

1. Gas 3/8" Barb Ball Lock Disconnect

2. hose to the psi gauge

3. where is the regulator?

#2 is a regulator (aka spunding valve). It's not just a gauge.

OP - can you put the keg into the same space the fermenter occupied? That is what I do. Luckily a keg fits into my wine fridge. Or is your fermenter stand alone?

I agree, temp control is important through the end of fermentation. Not to be confused with bottle conditioning which is post fermentation so higher temps do not have the same impact.

Maybe you can rig up some kind of water bath or cheap Craig's List fridge?

I agree, temp control is important through the end of fermentation. Not to be confused with bottle conditioning which is post fermentation so higher temps do not have the same impact.

Maybe you can rig up some kind of water bath or cheap Craig's List fridge?

No, my fermenter is temp controlled and not in a fridge. When I replace my kegerator, I'll probably use that as a fermentation fridge, but that is a ways off.OP - can you put the keg into the same space the fermenter occupied? That is what I do. Luckily a keg fits into my wine fridge. Or is your fermenter stand alone?

I agree, temp control is important through the end of fermentation. Not to be confused with bottle conditioning which is post fermentation so higher temps do not have the same impact.

Maybe you can rig up some kind of water bath or cheap Craig's List fridge?

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

Nice post!He's spunding, which means letting the fermentation finish in the keg. Fermentation of course produces CO2, and by allowing that CO2 to stay in the keg, it self-carbonates the beer, much like how bottle conditioning carbonates beer.

The spunding valve allows him to maintain a specific pressure during this time. It releases pressure when it gets higher than he wants.

*****

He has it set at 21psi, which normally would be too high for serving beer. But the beer must be kept at ferm temps, which would be, for example, in the mid 60-degree range.

Let's suppose he's got it at 63 degrees. According to the chart below, 21 psi at 63 degrees will give him 2.16 volumes of CO2 in his beer. When it's done fermenting, if he lowers the temp of the finished beer to, say, 40 degrees, the beer, being colder, will absorb CO2 more readily. That will drop the pressure to between 8 and 9 psi.

You can see this in the chart by looking across the 40-degree line until you find 2.16 volumes of CO2, and reading the associated pressure above. There's no "2.16" but it's between 2.10 and 2.20 volumes.

View attachment 635811

FWIW - I racked a little early since I was going out of town and I didn't want to completely miss the spund window.

This what I got from a highly carbed beer. Nice chewy head.

FTOYWDS - For those of you who don't Spund.... This was on day two after pitching.

I let it sit spunding for a 3 weeks while I was in Hawaii.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

One thing that's good about spunding is the short time from pitching to beer serving. If you're out you can fill the pipeline quickly. Especially if you're Brewing Hefeweizen.Pretty cool, @Schlenkerla. That idea never crossed my mind. I'm going to file this away for when I need something like that.

The last two beers I kegged at about 1-2 days after pitching. It's no surprise after pitching a 750ml starter on this 1.050 beer. I'm ok with losing a 1/2 gallon. I comp for this. I fill to about 50lbs keg weight in a closed transfer. (See picture).

My last beer was perking twice as fast as this video. I hydrated S04 at 8AM and added a pint of canned wort at 12pm. Pitched at 2AM Tuesday morning. At 8AM it was blasting a steady stream of CO2. Went to bed at midnight Tuesday, blasting the same way. Wednesday 8AM, I dropped it to the keg. To let it Spund. It was doing a slow blub, blub. It's at 16psi right now. Chilling it next week.

This video is 60 seconds. No delay or dwell in the flow of gas. I zoom out so you can see the keg purge.

- Joined

- Feb 19, 2017

- Messages

- 959

- Reaction score

- 1,217

@mongoose33 Thanks for the explanation, and walk thru on the carbonation chart. Much clearer now.

@Schlenkerla that looks freakin' awesome!

I found this set up on atlantic brewing supply, which looks like it will do the same as yours with a little less DIY.

FYI, before going on a couple of previous business tripa, I've primed in the keg with sugar and without CO2. Kinda hit and miss, starting out over pressurized, then about just right, then underpressurized before turning on the CO2 to finish it off. No blind triangle test, but these were sure tasty. Spunding looks to be a superior option. I'm planning to transfer from the primary into the keg when it gets near FG, ideally within 1 plato. Then turn on the CO2 if the carbonation goes too low.

Do I understand correctly, when spunding/naturally carbonating 5 gallons in the keg, do you need to add supplemental CO2 as the volume of beer in the keg decreases? Seems like you need to if the active fermentation is completed. Of course, if one were to spund in the keg at say 1015, and some of it while it is still fermenting down to FG at 1011, maybe it stays carbonated?

@Schlenkerla that looks freakin' awesome!

I found this set up on atlantic brewing supply, which looks like it will do the same as yours with a little less DIY.

FYI, before going on a couple of previous business tripa, I've primed in the keg with sugar and without CO2. Kinda hit and miss, starting out over pressurized, then about just right, then underpressurized before turning on the CO2 to finish it off. No blind triangle test, but these were sure tasty. Spunding looks to be a superior option. I'm planning to transfer from the primary into the keg when it gets near FG, ideally within 1 plato. Then turn on the CO2 if the carbonation goes too low.

Do I understand correctly, when spunding/naturally carbonating 5 gallons in the keg, do you need to add supplemental CO2 as the volume of beer in the keg decreases? Seems like you need to if the active fermentation is completed. Of course, if one were to spund in the keg at say 1015, and some of it while it is still fermenting down to FG at 1011, maybe it stays carbonated?

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

You basically need to keg and spund, on the down slope of fermentation. You want all of the carbonation to come from residual primary fermentation. Just like as if you prime and bottle carb. It's exactly the same but you don't have to add priming sugar into the keg. (If timed properly). Early is better than late.@mongoose33 Thanks for the explanation, and walk thru on the carbonation chart. Much clearer now.

@Schlenkerla that looks freakin' awesome!

I found this set up on atlantic brewing supply, which looks like it will do the same as yours with a little less DIY.

FYI, before going on a couple of previous business tripa, I've primed in the keg with sugar and without CO2. Kinda hit and miss, starting out over pressurized, then about just right, then underpressurized before turning on the CO2 to finish it off. No blind triangle test, but these were sure tasty. Spunding looks to be a superior option. I'm planning to transfer from the primary into the keg when it gets near FG, ideally within 1 plato. Then turn on the CO2 if the carbonation goes too low.

Do I understand correctly, when spunding/naturally carbonating 5 gallons in the keg, do you need to add supplemental CO2 as the volume of beer in the keg decreases? Seems like you need to if the active fermentation is completed. Of course, if one were to spund in the keg at say 1015, and some of it while it is still fermenting down to FG at 1011, maybe it stays carbonated?

In theory CO2 in the warm bottle is high until it's chilled. It would be almost a gusher warm but chilled the CO2 goes into solution (absorbed into the beer). Like the carbonation chart, pressure vs temperature.

It's like a big beginner bottle bomb, you rack too soon intentionally to create a bottle bomb situation but it vents to your set point on the regulator while warm at high pressures. This carbonates so you can chill and drink without the the slow carb time that comes with CO2 pressures that are set at serving pressures.

Last edited:

cloudybrewer

Well-Known Member

You basically need to keg and spund, on the down slope of fermentation.

How much trub ends up in the keg? On day 2 or 3 of fermentation, I still see a lot of mixing action and I would anticipate a lot of crap in the keg if I transferred that early.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

Yes. There's some trub getting into the keg it's a small amount. Even if you consider what's in suspension.How much trub ends up in the keg? On day 2 or 3 of fermentation, I still see a lot of mixing action and I would anticipate a lot of crap in the keg if I transferred that early.

I do a closed transfer with 3/16 hose and never have transfer issues. I typically have 2 pints that are a little muddy. Some people cut an inch off the bottom of the keg pick up tube. I have not. My guess if I did, I would not have the first two pints that look muddy. I still drink them for a probiotic.

My fermentor has a internal pick up tube. I typically leave about two quarts behind. I can adjust the height of pick up tube from the outside. I start at a horizontal and adjust down slightly until i see a little blip in the hose, then tilt up slightly. I adjust by twisting the ball valve. It's gasketed on the inside and has an o-ring on the outside. It rotates easy with no binding or scratching. It's made to pivot. The picture shows the pick up down. At sanitizing, I set my pick up at 45 degrees inside and the ball valve outside straight up and down (normal as you'd expect). So a 45 degree ball valve means the pick up is horizontal or straight down. I always have it tilted to my left as I face the fermentor. I fill to 50lbs on a scale.

I like that the beer is naturally carbed. It doesn't have long delay to carbonate. It's not got that carbonic acid bite from freshly force carbed beer. It's ready to drink from the point it's cold and on serving gas.

I brew Pale Ales, Rauchbier and Wheats. I like the great compact sedimentation of S04 on pale ales. Wheats are cloudy regardless. I like to use WB06. My Rauchbiers are fermented with S05, SO4, S33, and WB06. With exception of WB06 it's drops pretty clean.

This first beer picture below is Pistachio Rauchbier using S04. The smoke is from using pistachio shell instead of wood chips.

The 2nd beer picture is that same beer midway through the keg.

The 3rd beer picture is my 2 pull from my 2nd Pistachio Rauch Weissbier using WB06. 5AM one Saturday morning before starting a brew day. It was pretty humid that morning. It's condensated pretty good. Think I was the last week in June.

https://www.anvilbrewing.com/-p/anv-fv-7.5gal.htm

Last edited:

cloudybrewer

Well-Known Member

Yes. There's some trub getting into the keg it's a small amount. Even if you consider what's in suspension.

Thank you!

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

I've been pitching bigger lately and found day 3 or 4 it's done and really too late to spund. One air bubble passes maybe every several minutes.How much trub ends up in the keg? On day 2 or 3 of fermentation, I still see a lot of mixing action and I would anticipate a lot of crap in the keg if I transferred that early.

This last go around I made a starter with a dry pack of S04. Hydrated first then dumped the hydrated yeast into a quart jar on my stir plate. Using a pint of canned wort. Totaling about 3/4 of a quart. In 6 hours it was at high krausen. The bubble passing was like a Burping/Farting Gatling Gun. It was hard to hear the separate bubbles passing but I could see the stream in the growler.

My point is I think it settles quickly with a healthy sized slurry. All the available food is gone quite fast then drops the fermentation activity. It really ends abruptly. Once I got home from work late 7PM, felt lazy didn't rack to the keg. The next day at 7AM it was too late, I barely got 8psi for carbonation at 68F.

This last batch is primed now at 18 psi. It bumped up 2 psi in the last day or so. Yesterday was day # 7 from pitching.

You can spund with priming sugar. It's a safe bet if you think you missed the spund window. It'll just vent the extra CO2.

Last edited:

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

Another fews thoughts about clarity in the keg. This was a hesitation I had starting down this path with spunding.

1) Having very clean beer going to BK is important. Post mash, I recirculate 30 minutes with a pump and return manifold on my mash tun. Wort to the BK is nearly as clear as you would expect in a finished beer. I have a clear section of return line as a means to check clarity.

2) I use Brewtan-B in place of normal fining agent (like Irish Moss or Whirlfloc). This helps with Haze and my use of copper in my BK. Fenton Reaction or Negative effects of HSA.

https://wyeastlab.com/brewtan

3) I don't stir continually in the BK while chilling. I do give it one gentle stir right the time I kill the heat and start the chiller. I want the trub to move to the center and remain in big chunks. Stirring vigorously helps chill faster but it breaks up the trub particles into finer bits. I let it cool with a 3/8" copper chiller. I drain slowly and leave a quart of wort and trub behind. Not stirring lengthens the cooling time, but also allows more time for the trub to settle.

All three of these actions keeps trub out of my kegs since I elect to spund. There's less of that gunk needing to drop out of suspension. Clearer going into my keg, means clearer coming out of my tap.

I also make it a point of flushing my lines and faucet after a keg kicks.

1) Having very clean beer going to BK is important. Post mash, I recirculate 30 minutes with a pump and return manifold on my mash tun. Wort to the BK is nearly as clear as you would expect in a finished beer. I have a clear section of return line as a means to check clarity.

2) I use Brewtan-B in place of normal fining agent (like Irish Moss or Whirlfloc). This helps with Haze and my use of copper in my BK. Fenton Reaction or Negative effects of HSA.

https://wyeastlab.com/brewtan

3) I don't stir continually in the BK while chilling. I do give it one gentle stir right the time I kill the heat and start the chiller. I want the trub to move to the center and remain in big chunks. Stirring vigorously helps chill faster but it breaks up the trub particles into finer bits. I let it cool with a 3/8" copper chiller. I drain slowly and leave a quart of wort and trub behind. Not stirring lengthens the cooling time, but also allows more time for the trub to settle.

All three of these actions keeps trub out of my kegs since I elect to spund. There's less of that gunk needing to drop out of suspension. Clearer going into my keg, means clearer coming out of my tap.

I also make it a point of flushing my lines and faucet after a keg kicks.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

FYI - Copied from another post.....

I got this at Menards for under $10. The regulator is $4.99 and the 0-60psi gauge was $3.99.

It comes with 0-200psi gauge which is too big for spunding.

I just repaired the links here... If these stop working go to the Menards website and search pressure regulator. Any home improvement store that sells supplies for painting equipment or compressed air tools will have these. Maybe not this cheap. They'll do the job.

https://www.menards.com/main/tools-...-c-12917.htm?tid=-5239484310645308479&ipos=18

https://www.menards.com/main/tools-...-c-12917.htm?tid=-5239484310645308479&ipos=22

I got this at Menards for under $10. The regulator is $4.99 and the 0-60psi gauge was $3.99.

It comes with 0-200psi gauge which is too big for spunding.

I just repaired the links here... If these stop working go to the Menards website and search pressure regulator. Any home improvement store that sells supplies for painting equipment or compressed air tools will have these. Maybe not this cheap. They'll do the job.

https://www.menards.com/main/tools-...-c-12917.htm?tid=-5239484310645308479&ipos=18

https://www.menards.com/main/tools-...-c-12917.htm?tid=-5239484310645308479&ipos=22

Recapping the pieces left to right.

1) 1/4 NPT Brass plug, screwed into the high pressure side. Using Teflon tape.

2) The regulator and gauge.

3) 1/4 NPT to 3/16 Brass hose barb, screwed into the low pressure side. Using Teflon tape.

4) 3/16 Hose about 12" long, attached with hose clamp (on both ends).

5) 3/16 barb to 1/4 Female Flare Swivel.

6) Quick Disconnect ball-lock that has 1/4 flare.View attachment 623026

Copied from, "What I did for beer today" thread.

The spund is typically with a set point to vent. This is a regulator with the quick disconnect on the low pressure side. The high side is plugged. The over pressure CO2 vents via the regulator.

In this case I have it to the max, plan to dial it back once it hits something over 16psi. Typically I preset it with an empty keg that's pressurized. I turn up the gas to 30 psi on my draft CO2. Then connect the spund and dial it back until it vents and the pressure drops, giving it a quarter turn to stop it at my set point. Then I'm ready to put it on a keg to spund beer at that pressure.

Last edited:

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

... picture for the post above.

Great stuff, can’t wait till my valve arrives

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

Post pictures of your first spunded beer!Great stuff, can’t wait till my valve arrives

If you use one of these, the sediment in the keg doesn't matter: https://www.williamsbrewing.com/Top-Draw-Beer-Pick-Up-Tube-P4643.aspx

I have many of those floating pickups. They can have big foaming problems if they form a vortex to the surface while dispensing. I was able to defeat that by cutting a hole in the silicone tube just behind where it sticks over the float tube.

- Joined

- Feb 19, 2017

- Messages

- 959

- Reaction score

- 1,217

Ok, I got my spunding set up from Atlantic Brewing. Only issue is the gauge just goes to 15 psi (photo when I bought it showed 60psi). Anyhoo, I kegged a 1933 Kidd AK about 24 hours ago. The gauge barely moved in 24 hours, but I pulled the relief value just to double check and it's definitely carbonating. Also, when I shook the keg, the gauge went from 12 to 14. I'll slap it in the fridge in a day or two and then test it out.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

How long did you wait for the pressure to build up?Ok, I got my spunding set up from Atlantic Brewing. Only issue is the gauge just goes to 15 psi (photo when I bought it showed 60psi). Anyhoo, I kegged a 1933 Kidd AK about 24 hours ago. The gauge barely moved in 24 hours, but I pulled the relief value just to double check and it's definitely carbonating. Also, when I shook the keg, the gauge went from 12 to 14. I'll slap it in the fridge in a day or two and then test it out.

Looks like 24 hours from here...

twd000

Well-Known Member

I have many of those floating pickups. They can have big foaming problems if they form a vortex to the surface while dispensing. I was able to defeat that by cutting a hole in the silicone tube just behind where it sticks over the float tube.

I've had the vortex problem on one of my kegs, but not others. Haven't figured out what the difference it yet.

MY floating dip tubes are a DIY job with a "wine filter" screen leading into a draw tube. I am experimenting with dropping a couple stainless washers to add weight and sink the intake below the liquid level.

I use the wine filter because I saw it on the Clear Beer Draft System, and it's supposed to filter out sediment like dry hops, etc.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

DuhHow long did you wait for the pressure to build up?

I missed that, I typically give it 7 days.Looks like 24 hours from here...

- Joined

- Feb 19, 2017

- Messages

- 959

- Reaction score

- 1,217

@Schlenkerla You typically wait 7 days, then into the fridge for how long? Curious why 7 days? I brew generally low gravity English style ales (1040 is a big beer for me, and I do a lot of 1030), so I find these ferment out the last 4-5 gravity points in a day or two. Does it take longer for the C02 to fully carbonate? Do you shake your keg during spunding to speed up the CO2 absorption? Just curious what your experience is...

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

I wait that long for it to fully finish. I'm lax about temp control since all I make are ales. I limit my temps to a max of 72-73F though.@Schlenkerla You typically wait 7 days, then into the fridge for how long? Curious why 7 days? I brew generally low gravity English style ales (1040 is a big beer for me, and I do a lot of 1030), so I find these ferment out the last 4-5 gravity points in a day or two. Does it take longer for the C02 to fully carbonate? Do you shake your keg during spunding to speed up the CO2 absorption? Just curious what your experience is...

A large part of the wait is to get more of the yeast to flocculate. Especially if it's not a hefeweizen.

In the fridge 24-48 hours. The first few beers while good will have large bubbles if you pull a pint at 24 hrs.

I'm typically doing 10lb grain bills myself. I seem to like a 1.053 or 5.6% beer. A medium session.

Carolina_Matt

Well-Known Member

- Joined

- Jan 24, 2018

- Messages

- 482

- Reaction score

- 255

Ok, I got my spunding set up from Atlantic Brewing. Only issue is the gauge just goes to 15 psi (photo when I bought it showed 60psi). Anyhoo, I kegged a 1933 Kidd AK about 24 hours ago. The gauge barely moved in 24 hours, but I pulled the relief value just to double check and it's definitely carbonating. Also, when I shook the keg, the gauge went from 12 to 14. I'll slap it in the fridge in a day or two and then test it out.

Thanks for the note about 15 psi. I almost bought two of them from Atlantic the other day, but I delayed because they only had 1 in stock. I saw similar-looking versions elsewhere that only went up to 15 psi, so I had been curious about that. It looks like I'll get the one on ebay that goes higher.

A few things:

1) I have the spunding valve from AIH (homebrewing.org) and they go up to 60PSI

2) When I transfer to the spunding vessel (keg) I often see a delay before the pressure starts to rise. I attribute this to the CO2 that broke out of solution during the transfer, and so the liquid isn't saturated with CO2 anymore and you have to get to that point first before the pressure starts to build.

3) I have made a lot of english ales (or at least english ale yeast) in the 1.035-1.045 range and they usually ferment to the point of transfer in 2-3 days and then another day to finish spunding. I often give it one more day just due to life's timing, but that is it.

4) Another alternative with a screen are the cask widgets. I have both the ball floats and the cask widge(https://www.ukbrewing.com/CaskWidge_Float_Red_p/40176.htm).

1) I have the spunding valve from AIH (homebrewing.org) and they go up to 60PSI

2) When I transfer to the spunding vessel (keg) I often see a delay before the pressure starts to rise. I attribute this to the CO2 that broke out of solution during the transfer, and so the liquid isn't saturated with CO2 anymore and you have to get to that point first before the pressure starts to build.

3) I have made a lot of english ales (or at least english ale yeast) in the 1.035-1.045 range and they usually ferment to the point of transfer in 2-3 days and then another day to finish spunding. I often give it one more day just due to life's timing, but that is it.

4) Another alternative with a screen are the cask widgets. I have both the ball floats and the cask widge(https://www.ukbrewing.com/CaskWidge_Float_Red_p/40176.htm).

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

A few things:

1) I have the spunding valve from AIH (homebrewing.org) and they go up to 60PSI

2) When I transfer to the spunding vessel (keg) I often see a delay before the pressure starts to rise. I attribute this to the CO2 that broke out of solution during the transfer, and so the liquid isn't saturated with CO2 anymore and you have to get to that point first before the pressure starts to build.

3) I have made a lot of english ales (or at least english ale yeast) in the 1.035-1.045 range and they usually ferment to the point of transfer in 2-3 days and then another day to finish spunding. I often give it one more day just due to life's timing, but that is it.

4) Another alternative with a screen are the cask widgets. I have both the ball floats and the cask widge(https://www.ukbrewing.com/CaskWidge_Float_Red_p/40176.htm).

NateBrew is right it takes a day or so for pressure to develop.

I brew on Mondays typically, so by Wednesday or Thursday I'm kegging. Then come Monday they are usually at a peak pressure. I'll pop them in the fridge after a full week on spund. They could go earlier. It's partly depends on my mood. I spund to 20psi.

- Joined

- May 28, 2018

- Messages

- 3,041

- Reaction score

- 2,463

Aint rocket science fellers, all you need is a gauge and let some CO2 off regularly when it gets higher than you want it. Other spunding accessories are just to add convenience, but also easy to do. {;

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,896

The hardest part for n00b spundoids is the timing of when to do it. Early is better than late.Aint rocket science fellers, all you need is a gauge and let some CO2 off regularly when it gets higher than you want it. Other spunding accessories are just to add convenience, but also easy to do. {;

I make note of the high krausen, and pull a sample (for a fast ferment test FFT) or gravity checks to know where it's at when you drop to the keg. It's easy enough as soon as the high krausen or peak bubble passing subsides, then it's time to drop to the keg and spund. Spund until you see it hit the set point. If it's still cranking the spund valve will vent over the set point. So, my set point is 20psi, after it hits that I can still check my fast ferment test for the FG.

Much of this assumes you're doing a closed transfer too.

Last edited:

- Joined

- May 28, 2018

- Messages

- 3,041

- Reaction score

- 2,463

I agree timing is the thing may take a little experience. In my case, I do a trub dump and gravity check when fermantaion begins to slow. I then closed transfer to kegs when about .01-.006 above expected gravity. That assures I hit the 30PSI I shoot for.

Of course sometimes I can't hit timing just right, usually due to being distracted by work. Then I just make up the difference with forced carbing. It is much better partially spunded than 100% forced carbed.

Recently, I kegged when it had more to go than .006 to go , due to unfamiliar yeast. No problem, daily check with gauge and vent or set spunding valve to set point. I have spunding valves I made, but chose to vent that batch manually so I could track progress of final fermentation, out of curiosity.

Of course sometimes I can't hit timing just right, usually due to being distracted by work. Then I just make up the difference with forced carbing. It is much better partially spunded than 100% forced carbed.

Recently, I kegged when it had more to go than .006 to go , due to unfamiliar yeast. No problem, daily check with gauge and vent or set spunding valve to set point. I have spunding valves I made, but chose to vent that batch manually so I could track progress of final fermentation, out of curiosity.