I know that the spike brewing website states that the 20 gallon kettle is 17.7 inches wide by 21.4 inches tall. Can someone with this kettle out there verify the interior dimensions of this kettle as well as the top rim to rim dimension. I'm just trying to make some final decisions on basket size. Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spike brewing kettle dimensions

- Thread starter Nmnbrewer

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

1MadScientist

Well-Known Member

The diameter is 45 cm or 17.72 inches.

The height should be the reported 54 cm to the top. It is 50.4 cm or 19.82 inches to the 20 gallon mark.

The height should be the reported 54 cm to the top. It is 50.4 cm or 19.82 inches to the 20 gallon mark.

1MadScientist

Well-Known Member

I can get that for you tonight.

Aren't you going to have any ports at the bottom? Even a dip tube will take away from the height of a basket!

Aren't you going to have any ports at the bottom? Even a dip tube will take away from the height of a basket!

1MadScientist

Well-Known Member

It's 53 cm from the top to the flat area before the taper.

1MadScientist

Well-Known Member

mcgimpkins

Well-Known Member

- Joined

- Feb 23, 2014

- Messages

- 201

- Reaction score

- 56

The reason I ask this is because I'm having a basket made that will sit on the rim with tabs as opposed to feet and I want to have adequate clearance from the element. Thanks

Hey Nmnbrewer I have a 20 Gallon Spike Brew kettle that I had a basket made for. My dimensions were: Basket Diameter:16.5, Basket height:17.5 with 3" legs on the kettle for a grand total of 20.5" on the basket. I had 4 ports put on the bottom as well (thermowell, element, main port, and recirculate port). At that height it all fits pretty snug with the lid just barely clearing the top of the basket.

Hey Nmnbrewer I have a 20 Gallon Spike Brew kettle that I had a basket made for. My dimensions were: Basket Diameter:16.5, Basket height:17.5 with 3" legs on the kettle for a grand total of 20.5" on the basket. I had 4 ports put on the bottom as well (thermowell, element, main port, and recirculate port). At that height it all fits pretty snug with the lid just barely clearing the top of the basket.

That's pretty much exactly the basket that I'm going to have made except I'm going with rim tabs as opposed to legs. I don't really care if the lid fits on it with the basket or not. I'm also going to have the basket made wider at 17.25". Your port arrangement sounds just like mine as well. I'd be really interested to hear from you about your brewing experiences with this setup pros and cons.

mcgimpkins

Well-Known Member

- Joined

- Feb 23, 2014

- Messages

- 201

- Reaction score

- 56

Your port arrangement sounds just like mine as well. I'd be really interested to hear from you about your brewing experiences with this setup pros and cons.

I like it a lot, I did things a little different than some other people, but in general I get good efficiency and can brew 5-10 gallons easily and can probably squeeze 15 gallons out of it as long as it is not a high gravity beer. That being said, I don't see myself doing 15 gallon batches, but it is nice to have options.

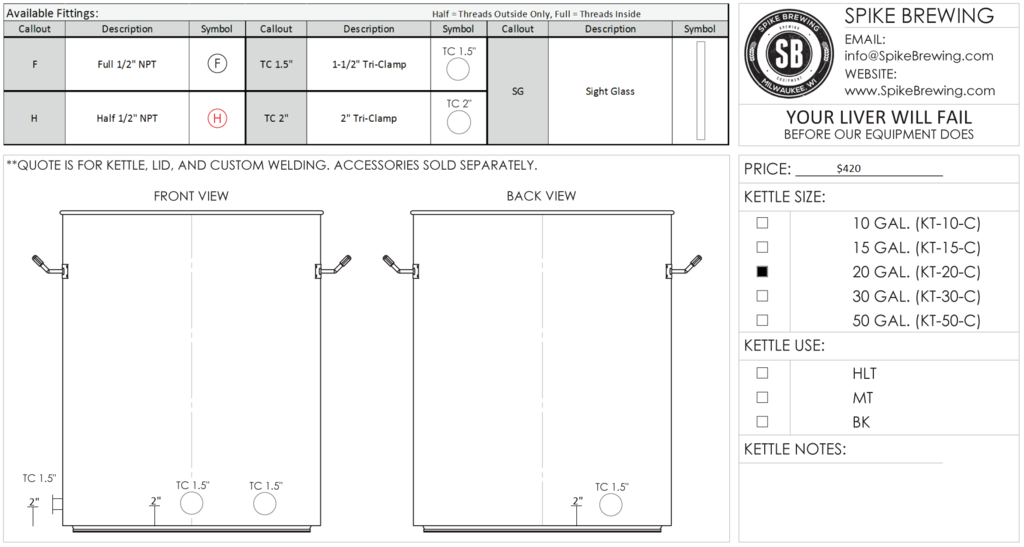

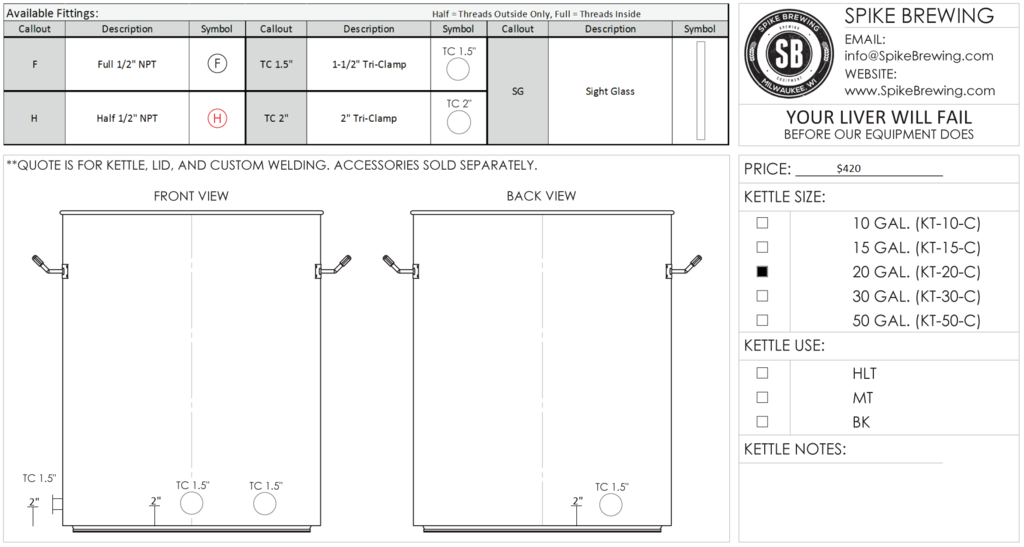

Here is my sheet from Spike

I would probably change the layout of the rear port because unbeknownst to me, that location is where Spike marks the Kettle, it is not a big deal, however I kind of wish I would have known before ordering the pot:

Here are some other pics of the pot, I ordered a solid sided basket from Colorado Brewing Systems. I built a custom whirlpool arm mimicking the one they have in their systems, but didn't have much luck with it. I ended up finding the SS Brew Tech Manifold for Mash Re-Circulation that works pretty great.

I'm also going to have the basket made wider at 17.25".

I would probably recommend against that, I purposely made mine 1" smaller than the pot, since Colorado Brewing Systems had recommended it. In addition I questioned @FreddyMar3 about his system (see: https://www.homebrewtalk.com/showthread.php?t=573718) He stated:

FreddyMar3 said:I would give myself an extra 1/4 inch of play on the basket diameter. I cut it REALLY close and sometimes accidentally drip down the side of the kettle a bit as I'm putting the hangers on the rim.

For those 2 reasons I made it 16.5" in diameter, and I have not been upset with the fit.

I hope this helps you.

Trainman28

Active Member

- Joined

- Oct 20, 2016

- Messages

- 27

- Reaction score

- 10

Nice looking pot mcgimpkins! Do you mind sharing what Spike charged for the pot + the 4 TC welds?

mcgimpkins

Well-Known Member

- Joined

- Feb 23, 2014

- Messages

- 201

- Reaction score

- 56

Yeah it is on the first picture, it was $420. The basket cost $204 from Colorado Brew Supply. All the other fittings tri-clamp and camlock I bought from http://www.bargainfittings.com/.

I like it a lot, I did things a little different than some other people, but in general I get good efficiency and can brew 5-10 gallons easily and can probably squeeze 15 gallons out of it as long as it is not a high gravity beer. That being said, I don't see myself doing 15 gallon batches, but it is nice to have options.

Here is my sheet from Spike

I would probably change the layout of the rear port because unbeknownst to me, that location is where Spike marks the Kettle, it is not a big deal, however I kind of wish I would have known before ordering the pot:

Here are some other pics of the pot, I ordered a solid sided basket from Colorado Brewing Systems. I built a custom whirlpool arm mimicking the one they have in their systems, but didn't have much luck with it. I ended up finding the SS Brew Tech Manifold for Mash Re-Circulation that works pretty great.

I would probably recommend against that, I purposely made mine 1" smaller than the pot, since Colorado Brewing Systems had recommended it. In addition I questioned @FreddyMar3 about his system (see: https://www.homebrewtalk.com/showthread.php?t=573718) He stated:

For those 2 reasons I made it 16.5" in diameter, and I have not been upset with the fit.

I hope this helps you.

So it's pretty much for cleanliness sake then. I can see that. Thanks for the link to the other build as well. That is one that I hadn't seen yet. We all seem to be thinking the same thing. One advantage we would have over him is a small batch with the larger diameter basket. At least thats my thinking. I'm glad to hear that I'll most likely be able to do some low gravity 15 gallon batches.

Trainman28

Active Member

- Joined

- Oct 20, 2016

- Messages

- 27

- Reaction score

- 10

Is there a reason why you went with the solid sided basket from CO compared to the mesh sided one from AF?

mcgimpkins

Well-Known Member

- Joined

- Feb 23, 2014

- Messages

- 201

- Reaction score

- 56

Is there a reason why you went with the solid sided basket from CO compared to the mesh sided one from AF?

What I brewed with before was a smaller 15 gallon pot with a mesh sided basket. Originally when I build this larger system, I thought a solid sided basket would give me better efficiency, since all the water had to be cycled though the mash like in a 3 pot RIMS system, and none could escape down the sides like a conventional mesh-sided basket.

After playing with it a bunch I really don't see a huge difference one way or the other between to two. I might on certain beers get efficiencies 1% better, other times, I am hitting the same numbers I did with the mesh-sided basket. So I'm not really seeing a big advantage one way or the other on mesh vs solid sided baskets.

One piece of advise I do have for anyone getting a basket made, get a quote from Arbor Fab, Utah Biodiesel Supply, and Colorado Brewing Systems (they make solid and mesh sided baskets) and see whom gives you the best price. I had a custom hop basket made for me in the past, and for whatever reason Utah Biodiesel Supply gave me a quote $10 less than Arbor Fab even though I am pretty sure that the basket was made at the same place.

Trainman28

Active Member

- Joined

- Oct 20, 2016

- Messages

- 27

- Reaction score

- 10

I gotcha. Thanks for posting. I'm really wanting to get into ebiabasket brewing and I'm in the research/planning stages for what I want. I'm pretty close to knowing that thanks to you and several others here on hbt. I'm just waiting after doing taxes this year to pull the trigger. Really like the SB pot and TC setup you have. Hoping to match that with a basket and auber instruments control panel

mcgimpkins

Well-Known Member

- Joined

- Feb 23, 2014

- Messages

- 201

- Reaction score

- 56

Sounds like a plan, I don't have any experience with the auber instruments control panel, but feel free to PM me any questions or specifics as you get into building your system.

- Joined

- Dec 31, 2017

- Messages

- 75

- Reaction score

- 32

What I brewed with before was a smaller 15 gallon pot with a mesh sided basket. Originally when I build this larger system, I thought a solid sided basket would give me better efficiency, since all the water had to be cycled though the mash like in a 3 pot RIMS system, and none could escape down the sides like a conventional mesh-sided basket.

After playing with it a bunch I really don't see a huge difference one way or the other between to two. I might on certain beers get efficiencies 1% better, other times, I am hitting the same numbers I did with the mesh-sided basket. So I'm not really seeing a big advantage one way or the other on mesh vs solid sided baskets.

One piece of advise I do have for anyone getting a basket made, get a quote from Arbor Fab, Utah Biodiesel Supply, and Colorado Brewing Systems (they make solid and mesh sided baskets) and see whom gives you the best price. I had a custom hop basket made for me in the past, and for whatever reason Utah Biodiesel Supply gave me a quote $10 less than Arbor Fab even though I am pretty sure that the basket was made at the same place.

I had been thinking of this option as well. I can save a few bucks buying a solid kettle and welding a flas bottom into the bottom. The reason I was thinking doing this style setup was I could pull basket out and fly sparge while it hangs over kettle. Have u tried this

Also when your recirculating. I suppose I can only recirculat as fast as the basket can drain. Do u find that to be an issue.

Also I can’t see any of the pics for some reason.

mcgimpkins

Well-Known Member

- Joined

- Feb 23, 2014

- Messages

- 201

- Reaction score

- 56

So Photobucket started flagging some of my images as getting "high traffic", and for my convenience decided I should be charged to share these images with other people. So I moved them to another image hosting site that does not seem to do that. Below is the original message with the pics. I tried to edit the original however, Homebrewtalk will not let me.

--------------------------------------------------------------------------------------------------

I like it a lot, I did things a little different than some other people, but in general I get good efficiency and can brew 5-10 gallons easily and can probably squeeze 15 gallons out of it as long as it is not a high gravity beer. That being said, I don't see myself doing 15 gallon batches, but it is nice to have options.

Here is my sheet from Spike

I would probably change the layout of the rear port because unbeknownst to me, that location is where Spike marks the Kettle, it is not a big deal, however I kind of wish I would have known before ordering the pot:

Here are some other pics of the pot, I ordered a solid sided basket from Colorado Brewing Systems. I built a custom whirlpool arm mimicking the one they have in their systems, but didn't have much luck with it. I ended up finding the SS Brew Tech Manifold for Mash Re-Circulation that works pretty great.

I would probably recommend against that, I purposely made mine 1" smaller than the pot, since Colorado Brewing Systems had recommended it. In addition I questioned @FreddyMar3 about his system (see: https://www.homebrewtalk.com/showthread.php?t=573718) He stated:

For those 2 reasons I made it 16.5" in diameter, and I have not been upset with the fit.

I hope this helps you.

--------------------------------------------------------------------------------------------------

I like it a lot, I did things a little different than some other people, but in general I get good efficiency and can brew 5-10 gallons easily and can probably squeeze 15 gallons out of it as long as it is not a high gravity beer. That being said, I don't see myself doing 15 gallon batches, but it is nice to have options.

Here is my sheet from Spike

I would probably change the layout of the rear port because unbeknownst to me, that location is where Spike marks the Kettle, it is not a big deal, however I kind of wish I would have known before ordering the pot:

Here are some other pics of the pot, I ordered a solid sided basket from Colorado Brewing Systems. I built a custom whirlpool arm mimicking the one they have in their systems, but didn't have much luck with it. I ended up finding the SS Brew Tech Manifold for Mash Re-Circulation that works pretty great.

I would probably recommend against that, I purposely made mine 1" smaller than the pot, since Colorado Brewing Systems had recommended it. In addition I questioned @FreddyMar3 about his system (see: https://www.homebrewtalk.com/showthread.php?t=573718) He stated:

For those 2 reasons I made it 16.5" in diameter, and I have not been upset with the fit.

I hope this helps you.

mcgimpkins

Well-Known Member

- Joined

- Feb 23, 2014

- Messages

- 201

- Reaction score

- 56

I had been thinking of this option as well. I can save a few bucks buying a solid kettle and welding a flas bottom into the bottom. The reason I was thinking doing this style setup was I could pull basket out and fly sparge while it hangs over kettle. Have u tried this

Also when your recirculating. I suppose I can only recirculat as fast as the basket can drain. Do u find that to be an issue.

Also I can’t see any of the pics for some reason.

I have not tried fly sparging, there is no reason you could not fly sparge, I just do not have the patience to do it. I usually get 1-2 gallons from the kettle before doughing in, put them in a 2 gallon thermos. After I pull the grains, I stick a lid that I have drilled holes into in the basket, then slowly dump the water on top of the lid. I guess it is the equivalent of batch sparging. Either way it seems to work well for rising the grains.

You have to check the pot while mashing to make sure that the basket is draining. Most of the time if you having the pump set to half open does fine. If you are doing a wheat beer or something that may be gummy, it seems best to throw some rice hulls in, then you have no problems at all.

The big issue which I am sure you are aware of, is keeping the element submerged. On my old setup (which was actually an open sided basket), I burned one beer with the element. It is too nasty to drink and ended up getting dumped in the back yard.

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 13

- Views

- 2K

- Replies

- 7

- Views

- 1K

- Replies

- 0

- Views

- 522

- Replies

- 1

- Views

- 943