hunmojo, you won't need any rice hulls. As for the 20L vs 50L unit, it's just a question of scale, not about pump or heating power as such. It all boils down to how many litres of beer you want per brew.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speidel Braumeister (brewmaster)

- Thread starter FiveKaiBrewing

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Ragtop232

Well-Known Member

If money is not an issue, I think I would go for the 50L just for flexibility. I personally have the 20L and it's just perfect for me. I do 6 gal batches and server is 3 gal corny kegs. However, I couldn't do big, high gravity beers in this setup without modifying my current malt pipe. The way I do that now is just add DME to bring up to gravity. A plus for the 20L is it's ease of lifting the malt pipe full of grain out of the kettle when finished mashing. But, for the flexibility aspect and future growth into 10 gal batches, the 50L would be a better choice. YMMV

Jim

Jim

In my experience 13kg is close to the maximum load of the 50L malt pibe, but I think one should be carefull not to go to the absolute limit. I have measured the flow during my mashings, and filling the pibe too much reduces the flow considerably, although the pumps are able to push through. I think it's adviceable not to go above 12.5kg (27.5lbs).

Thanks. I think I will try max of 26 lbs with 2 lbs of rice hulls next. I prefer to do a 20G batch if possible.

ok i have gotten through to page 130 roughly... and iv decided to get an BM. now the question is 20 or 50L.,.... ????

im happy to say that money is not an issue for once in my life. when deciding which system to get. so on to the other pros and cons.....

1. I am planing on using this system for a pilot setup to test batches for up cumming brews.

2. all my beers usually fall between 5-6% , but i do like to experiment. and if im spending this kind of cash i dont want to be held back.

3. i am brewing in doors, and with my current cooling fridges set up i can only accommodate 20L-30l batches for fermentation.

the only reason I am considering the 50L with the 20l malt pipe is because it seems to be better equipped with the pumps and heating element. wich would allow me to better stuff the pipe with malt.

another thing im worried about is the lack of rice hulls available here in hungary....it does not exist......will this pose a problem with channeling. or am i thinking correctly assuming that the 50l w 20l malt will solve this problem for me.

i also dont mind buying the hood if it helps, but i didnt really get a good idea weather its helpfull or not, people either say without it boil is lacking with it its splashing all over...9at least when it comes to the 20L)

please honest answers are appreciated regardless of which size yOU use (try not to be biased towards your system) will really help me out. Im ready to push the buy button, i just need to figure out if the 50/20 setup is better than the regular 20, if we are not looking at money here..... thanks guys...

Hunmojo,

I would recommend getting the 50L personally. With the 50L, you'll be able to get the 20L malt pipe should you wish to do 5-6 gallon batches. Something to note though: You'll be limited on the OG on either of these. You wouldn't be able to get the 50L, fit more grain and less water. The way this unit operates wouldn't allow for that unfortunately, so adding DME or corn sugar to your recipe would be necessary. Let me know if you have any specific questions - more than happy to help!

PS - The copper hood does help with the boil. It's somewhat expensive, but that and the insulation can definitely speed up the brew day / provide a more vigorous boil.

Cheers!

thanks for the input guys.

I think i am going to tackle this beast from another angle...

here is my next question. what is the smallest batch you can do on the regular 20 liter. not OG wise, but Liter wise.

(without doing a 3 hour boil ofcourse, lets keep i realistic to maybe 90 or close. ?)

is it possible to do nano brews. 10L batches and what would be the limits to those..?

does the og limit change, get lower? higher? pump problems.

I understand that you need a certain amount of water to make the circulation work, so I assume that is the minimum. But can you still pack the 5kg in the pipe with less water?

i think i read somewhere that the 20L has a 15L mark... if so... wouldnt filling up to that mark when mashing give me something closer to 10L at the end of boil.?

I think i am going to tackle this beast from another angle...

here is my next question. what is the smallest batch you can do on the regular 20 liter. not OG wise, but Liter wise.

(without doing a 3 hour boil ofcourse, lets keep i realistic to maybe 90 or close. ?)

is it possible to do nano brews. 10L batches and what would be the limits to those..?

does the og limit change, get lower? higher? pump problems.

I understand that you need a certain amount of water to make the circulation work, so I assume that is the minimum. But can you still pack the 5kg in the pipe with less water?

i think i read somewhere that the 20L has a 15L mark... if so... wouldnt filling up to that mark when mashing give me something closer to 10L at the end of boil.?

dinnerstick

Well-Known Member

you can't do 10L brews on the 20. i don't know what the minimum water level would be to circulate a low grain total, say 5kg. but the malt tube is 27d x 36h giving a volume of 21.2 liters (correct? it's early). so that's basically your absolute minimum for zero grain, before you start to displace some of that with grain. you would have to determine the grain absorption/displacement empirically, and i would bet that at the end of the exercise you are going to just wish you had more beer, not less....

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

sentfromspain

Well-Known Member

New question: I am going to be working with a 200 liter Braumeister, would it be feasible to - when chilling the wort - send the wort through one of those chilled beer taps? If you don't know what I'm referring to, google "chill rite."

My main doubt is that perhaps the flow from the whirlpool pumps would be greater than the amount of wort that could flow out of the tap. Those beer taps though get down to 28 degrees, and if I could include it in the cycle it would do wonders.

My main doubt is that perhaps the flow from the whirlpool pumps would be greater than the amount of wort that could flow out of the tap. Those beer taps though get down to 28 degrees, and if I could include it in the cycle it would do wonders.

Hey sentfromspain,

That's a good question. Can I answer with another though? -Why would you want to chill the wort through a tap tower? I honestly don't think that the 28°F is going to stay 28°F for too long with hot wort running through it. I think your best bet is to use a glycol unit, whirlpool and jacket for cooling. A lot of our customers use the glycol jacket in combination with a dual-counterflow chiller setup (cool in the Braumeister to about 150, then pump through two counterflows to pitching temp).

That would be my recommendation. It's possible that the tap system would work, but I think to get that down to 28°F you'd need a glycol system (correct me if I'm wrong) - so I would just recommend using the glycol system for the jacket instead. Hopefully that helps!

Cheers,

Matt

That's a good question. Can I answer with another though? -Why would you want to chill the wort through a tap tower? I honestly don't think that the 28°F is going to stay 28°F for too long with hot wort running through it. I think your best bet is to use a glycol unit, whirlpool and jacket for cooling. A lot of our customers use the glycol jacket in combination with a dual-counterflow chiller setup (cool in the Braumeister to about 150, then pump through two counterflows to pitching temp).

That would be my recommendation. It's possible that the tap system would work, but I think to get that down to 28°F you'd need a glycol system (correct me if I'm wrong) - so I would just recommend using the glycol system for the jacket instead. Hopefully that helps!

Cheers,

Matt

sentfromspain

Well-Known Member

Well, the people I work with got their BM from a company that tends to sell people really expensive equipment, push them out the door, and turn off their telephones. What they got with the BM was a system that takes, apparently, an hour and a half to cool the wort to 85 degrees. My cohorts have invested as much as they can really to get their new brewery off the ground, and so we are thinking of alternatives.

They already have a tap tower, and while you're right that it won't stay at 28 degrees for very long, perhaps it will help. I have also been kicking around the idea of going the "Australian no chill" route and throwing all 200 liters in a steel, hermetically sealed fermenter. I have no idea how long that would take to chill, but the no chill method has always worked great for me...

They already have a tap tower, and while you're right that it won't stay at 28 degrees for very long, perhaps it will help. I have also been kicking around the idea of going the "Australian no chill" route and throwing all 200 liters in a steel, hermetically sealed fermenter. I have no idea how long that would take to chill, but the no chill method has always worked great for me...

PrivateWiddle

Member

Hello, can you give me a clue which company you referred to, I'm about to get a BM & really want to use a good supplier. I'm in England, thanksWell, the people I work with got their BM from a company that tends to sell people really expensive equipment, push them out the door, and turn off their telephones. What they got with the BM was a system that takes, apparently, an hour and a half to cool the wort to 85 degrees. My cohorts have invested as much as they can really to get their new brewery off the ground, and so we are thinking of alternatives.

They already have a tap tower, and while you're right that it won't stay at 28 degrees for very long, perhaps it will help. I have also been kicking around the idea of going the "Australian no chill" route and throwing all 200 liters in a steel, hermetically sealed fermenter. I have no idea how long that would take to chill, but the no chill method has always worked great for me...

sentfromspain

Well-Known Member

The company is in Barcelona, called Cerveza Artesana. They are a bunch of thieves, but since you are in the UK I wouldn't worry about them.

Reality Check on Grain Absorption Rate for the 50L Braumeister:

I did the NB Surly Furious Clone AG recipe last night. Doubled the recipe for a 10 gallon batch.

Total grain weight: 24.8lbs (11.25kg)

Water collected: 57.2l (scaled up 4% from cold water volume of 55 liters)

Sparge Water: 12l @175F

Pulled the malt pipe off after waiting ~20 minutes after the last sparge pitcher added (4 pitchers total of 3l per) and let it drain over an old igloo cooler lid (former mash tun)

56.2l of 1.048 wort in the kettle

About an hour later, I found another 4 liters of 1.035 wort in the lid.

So...

57.2 mash water + 12 liters sparge = 69.2 liters Total

56.2+4 = 60.2 liters Net

69.2-60.2 = 9 liters absorbed by grain

9l/11.25kg = 0.8 l/kg of grain (~.1 gallon per pound)

Is this extremely atypical?!? I've done the math over and over, and I made it a point NOT to drink on this brew day in order to finalize my BS equipment profile and settings. Almost every BM thread I have read indicates anywhere from 1 - 1.66 liters per kg. My crush is fine, but not utterly pulverizing. Anyone ever get an absorption rate this low with their BM?

I did the NB Surly Furious Clone AG recipe last night. Doubled the recipe for a 10 gallon batch.

Total grain weight: 24.8lbs (11.25kg)

Water collected: 57.2l (scaled up 4% from cold water volume of 55 liters)

Sparge Water: 12l @175F

Pulled the malt pipe off after waiting ~20 minutes after the last sparge pitcher added (4 pitchers total of 3l per) and let it drain over an old igloo cooler lid (former mash tun)

56.2l of 1.048 wort in the kettle

About an hour later, I found another 4 liters of 1.035 wort in the lid.

So...

57.2 mash water + 12 liters sparge = 69.2 liters Total

56.2+4 = 60.2 liters Net

69.2-60.2 = 9 liters absorbed by grain

9l/11.25kg = 0.8 l/kg of grain (~.1 gallon per pound)

Is this extremely atypical?!? I've done the math over and over, and I made it a point NOT to drink on this brew day in order to finalize my BS equipment profile and settings. Almost every BM thread I have read indicates anywhere from 1 - 1.66 liters per kg. My crush is fine, but not utterly pulverizing. Anyone ever get an absorption rate this low with their BM?

goodgodilovebeer

Well-Known Member

On my 20L, I typically get absorption of roughly 1 litre per kilogram of malt. Yet, I only let the mash drain for about 10 minutes. I can see how another hour would get another litre or two, sure.

PrivateWiddle

Member

The company is in Barcelona, called Cerveza Artesana. They are a bunch of thieves, but since you are in the UK I wouldn't worry about them.

Thank you

Well, depends of the size of your chill rite.

I was using mine exactly the way you intend to. I disconected the tower tho and used pump to get beer from boiling vesel thru the lines.

When I had cooling water down to 0C I was able to cool 45 litters of worth from 95C down to 18C in one go.

And I used cooler which servers 6 taps, quite sizeable one.

For 200 litres , i would recomend you cool it down to some 50C or 60C with some other method and use this as a last step to get it down to pitching temp.

I was using mine exactly the way you intend to. I disconected the tower tho and used pump to get beer from boiling vesel thru the lines.

When I had cooling water down to 0C I was able to cool 45 litters of worth from 95C down to 18C in one go.

And I used cooler which servers 6 taps, quite sizeable one.

For 200 litres , i would recomend you cool it down to some 50C or 60C with some other method and use this as a last step to get it down to pitching temp.

New question: I am going to be working with a 200 liter Braumeister, would it be feasible to - when chilling the wort - send the wort through one of those chilled beer taps? If you don't know what I'm referring to, google "chill rite."

My main doubt is that perhaps the flow from the whirlpool pumps would be greater than the amount of wort that could flow out of the tap. Those beer taps though get down to 28 degrees, and if I could include it in the cycle it would do wonders.

Today I used 5kg of grist, mostly pilsner and pale ale, started with 26L, added 6L, ended up with 27L before the boil started. So that is exactly 1kg/L with quite a coarse crush, practically no flour at all.

You'll be limited on the OG on either of these. You wouldn't be able to get the 50L, fit more grain and less water. The way this unit operates wouldn't allow for that unfortunately, so adding DME or corn sugar to your recipe would be necessary. Let me know if you have any specific questions - more than happy to help!

I get around this by doing an extended boil (down to 5 gallons) for my high-gravity beers. This way I can achieve 1.1+ OGs with relative ease (that rhymes kinda). If the style calls for something that's not too melanoiden rich (like an Imperial IPA), I add DME. For some of the new people reading this thread and wondering if they should buy the Braumeister, see my "1 Year Brewing on The Braumeister" post for some insights into the machine's performance.

On that note, I haven't used my shorter mash pipe in over a year—if anybody wants to buy it, I might entertain the idea.

Someone mentioned in the first few pages mentioned running a mash, collecting the runnings and using them for another mash after removing the spent grain. Can anyone elaborate on this process a little bit? How does this change, if at all, the mash ph and does this mean you have to do two 60min mashes?

I'm going to brewing on these systems a lot in the near future and want to find a way to hit 7-8abv without using table sugar, extract, or boiling down to concentrate the wort.

I'm going to brewing on these systems a lot in the near future and want to find a way to hit 7-8abv without using table sugar, extract, or boiling down to concentrate the wort.

A little off topic, but does anyone have an issue with bitterness in their BM beers? My first batch was just a 5 gallon batch Kolsch recipe scaled up to 10 using the same hops and AA ratings. It seems to me like the bitterness just isn't what it used to be when I did 5 gal batches. It may just be me, but something seems a bit lacking in the bitterness department with this one.

dinnerstick

Well-Known Member

Does anybody know what the size and pitch of the center rod is on the 20L.

does pitch refer to thread? by size do you mean length? happy to help but a bit lost

dinnerstick

Well-Known Member

i don't have a thread gauge (nor calipers) so you'll have to wait for someone else to chime in on the thread, but the rod is 41 cm from the bottom of the kettle to the top of the threads. the bottom 1cm or so sits in a base, so only 40cm are proud. the diameter is 1cm, by measuring with a ruler, not calipers. i bet if you ask speidel directly via their website you will get the specs, they are pretty helpful, but i would hope someone on here will reply

OK, thought I'd get a couple of brews under my belt before I posted again. (That and recovered from another neck surgery!  )

)

The first brew was almost an epic disaster, trying to get use to new equipment, and new to all grain brewing, but the machine itself performed as expected. My efficiency was way off, in part due to too fine a crush mucking up the flow, and too short a mash (60 min for a dipa). I brewed the same recipe again, loosened up the mill to 1.2mm, and increased the mash to 90 minutes, and it made a big difference. Came real close to the target gravity, and finished with a much better end result. The recipe was based on Kiwi Crossing IPA from Midwest, I increased the malt bill and the hops, turned out to be one of my best brews so far!

I will be brewing Biermuncher's Tits Up IIPA in the next couple weeks. Looking forward to that!!

The first brew was almost an epic disaster, trying to get use to new equipment, and new to all grain brewing, but the machine itself performed as expected. My efficiency was way off, in part due to too fine a crush mucking up the flow, and too short a mash (60 min for a dipa). I brewed the same recipe again, loosened up the mill to 1.2mm, and increased the mash to 90 minutes, and it made a big difference. Came real close to the target gravity, and finished with a much better end result. The recipe was based on Kiwi Crossing IPA from Midwest, I increased the malt bill and the hops, turned out to be one of my best brews so far!

I will be brewing Biermuncher's Tits Up IIPA in the next couple weeks. Looking forward to that!!

mellowmonk

Member

- Joined

- Mar 18, 2013

- Messages

- 6

- Reaction score

- 0

Has anyone made an extension cord for their Braumeister that connects to a standard US dryer outlet (220 i think?). Most of the posts I have seen people are installing new receptacles or have modified the standard Braumeister cord. I have modified my Braumeister cord but it is short.

Could I buy this cord and rewire it with a dryer plug?

http://www.stayonline.com/detail.aspx?id=8951

Could I buy this cord and rewire it with a dryer plug?

http://www.stayonline.com/detail.aspx?id=8951

sebring96hbg

Well-Known Member

Has anyone made an extension cord for their Braumeister that connects to a standard US dryer outlet (220 i think?). Most of the posts I have seen people are installing new receptacles or have modified the standard Braumeister cord. I have modified my Braumeister cord but it is short.

Could I buy this cord and rewire it with a dryer plug?

http://www.stayonline.com/detail.aspx?id=8951

I bought this one....

http://www.stayonline.com/detail.aspx?id=11236

The male end matches up with my receptacle and the C13 end matches up with the 20L power port without any further mods. Without seeing a pic of your dryer outlet, it is difficult to provide an answer.

I have the 50L model and I'm turning it on this Saturday. So what I've learned so far. Nobody fully understands power. Saturday, I will! Your dryer/stove runs on 240v but your house doesn't have 240v like in europe. We don't have 240v on one leg and a neutral, we throw 120v down each leg delivering 220v. Check it out, stick a multimeter into your outlet, you'll find 240 across your two leads and 120 between each lead and the ground.

So I'm under the impression that this has not been a problem for anyone.

Md

So I'm under the impression that this has not been a problem for anyone.

Md

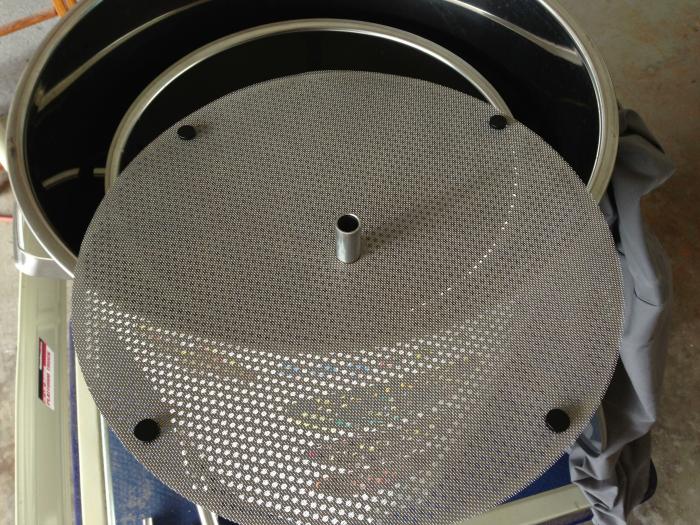

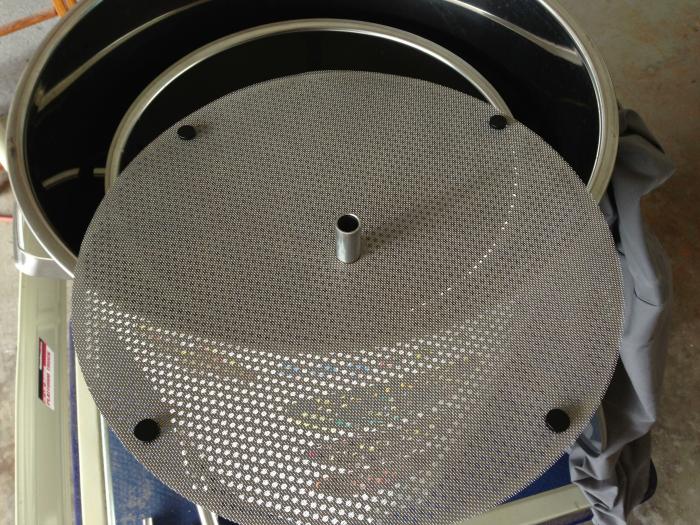

just thought I'd post my idea on how to hold the mesh to the plates on the BM. I originally used High Temp neodymium magnets (good to 300 F) , but the nickel plating corroded rather quickly and they weren't available with an epoxy coating like the ones I am going to try out. They are good to 176F or 80C, which should hold up. Available from K&J Magnetics #D82E. I will post whether they worked or not after my next brew. Hopefully this might help someone else out.

jdebonth

Well-Known Member

- Joined

- Mar 14, 2013

- Messages

- 51

- Reaction score

- 3

Hi all, I'm thinking of pulling the trigger on a BM, but I can't decide between the 20L and 50L. I am looking for a top of the line solution for recipe development. In the short term i will brew probably only 20L batches as I refine recipes, but in the future there may be situations where i want to brew double batches, and thus this flexibility would be great to have. The cost difference fortunately is not really a factor as I consider this to be a life long purchase.

So I would like to understand the cons of using the 20L malt pipe in the 50L unit as opposed to brewing 20L in a 20L BM. I know some posters have been brewing mainly 20L batches in the 50L systems, and some have mentioned wanting to switch to the 20L. What are the reasons for this?

What I can think of:

- 50L has larger footprint and hence more difficult to handle

- 50L more difficult to clean

- 50L with 20L malt pipe might make dumping grains into the mast ton more difficult as you need to drop scoop lower into the unit?

- more awkward to pull mash ton out after mashing?

- 50L needs 15amp plugs, fortunately my apartment is fitted with these so not an issue

- would need a larger conical fermenter (to be prepared for future 50L batches) and use this mainly with 20L batches, but i think this is a non-issue as I understand it is fine to ferment 20L in say a 55L fermenter.

Anything I missed?

On the plus (doing 20L in 50L BM) I think I get a more vigorous boil, better circulation due to dual pumps meaning I can really push the max gravity limits of the system.

The other option would be to buy a 20L and when double batches are required to do 2 consecutive brews (although) this is a bit more work, specially if double batches are needed more often down the road.

Any input is greatly appreciated!

So I would like to understand the cons of using the 20L malt pipe in the 50L unit as opposed to brewing 20L in a 20L BM. I know some posters have been brewing mainly 20L batches in the 50L systems, and some have mentioned wanting to switch to the 20L. What are the reasons for this?

What I can think of:

- 50L has larger footprint and hence more difficult to handle

- 50L more difficult to clean

- 50L with 20L malt pipe might make dumping grains into the mast ton more difficult as you need to drop scoop lower into the unit?

- more awkward to pull mash ton out after mashing?

- 50L needs 15amp plugs, fortunately my apartment is fitted with these so not an issue

- would need a larger conical fermenter (to be prepared for future 50L batches) and use this mainly with 20L batches, but i think this is a non-issue as I understand it is fine to ferment 20L in say a 55L fermenter.

Anything I missed?

On the plus (doing 20L in 50L BM) I think I get a more vigorous boil, better circulation due to dual pumps meaning I can really push the max gravity limits of the system.

The other option would be to buy a 20L and when double batches are required to do 2 consecutive brews (although) this is a bit more work, specially if double batches are needed more often down the road.

Any input is greatly appreciated!

Since you are looking long term on this and money isn't an object then I would go with the 50.

It will give you a better boil and more options for the long haul.

It will give you a better boil and more options for the long haul.

Similar threads

- Replies

- 2

- Views

- 426

- Replies

- 11

- Views

- 711

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)