I used Propane to do my soldering too. Also sand paper on the fitting and the kettle area is important.

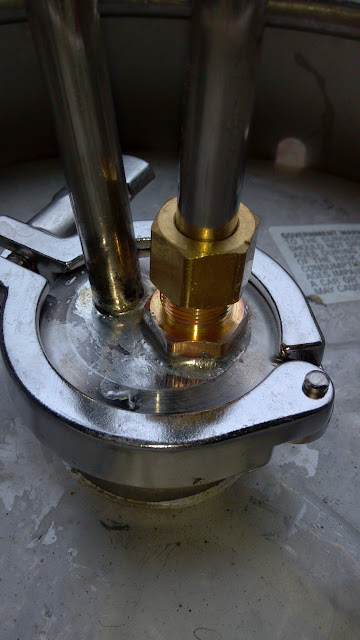

I did a LOT of looking into this before soldering a 1" Nut onto my Blichman kettles and found that propane will heat the solder up enough to melt. But is at a low enough temperature to cool fast enough to not allow the nut to "wander" before setting up. The Stay Clean helped too of course.

Here is some other tips I found.

Use a round ring of the solder the size of the hole in the kettle. Put it on the top of the kettle, and then place the nut on top of that. Heat the nut with the torch until the solder melts and then IMMEDIATELY remove the heat source. If not the solder will run.

Make sure to heat up the area on the kettle too, not just the fitting

I did a LOT of looking into this before soldering a 1" Nut onto my Blichman kettles and found that propane will heat the solder up enough to melt. But is at a low enough temperature to cool fast enough to not allow the nut to "wander" before setting up. The Stay Clean helped too of course.

Here is some other tips I found.

Use a round ring of the solder the size of the hole in the kettle. Put it on the top of the kettle, and then place the nut on top of that. Heat the nut with the torch until the solder melts and then IMMEDIATELY remove the heat source. If not the solder will run.

Make sure to heat up the area on the kettle too, not just the fitting

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)