steelerguy

Well-Known Member

As summer came on my basement was getting too hot to control fermentation temps. I had to go from warming my carboys up to needing to chill them, it was time to build something! I originally was going to fashion something with an old dorm refrigerator I had, but having to operate it without the door and trying to come up with something to seal decently but allow easy access seemed a bit difficult. I found the plans for the Son of Fermenation Chiller and decided that was the way to go.

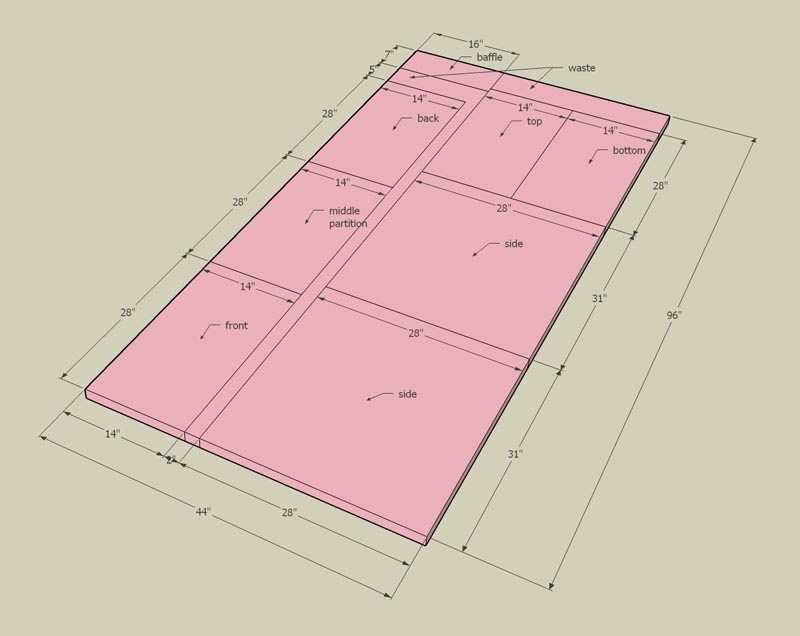

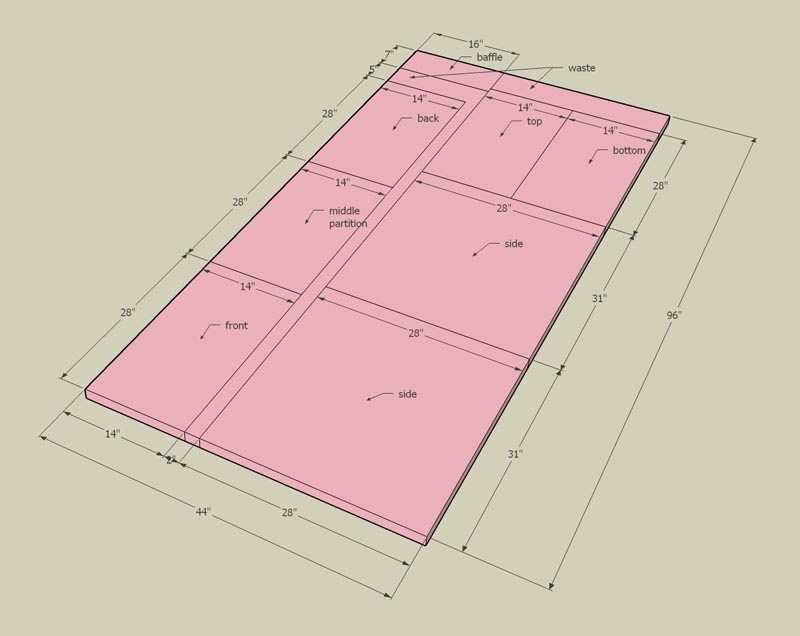

I went to Home Depot and Lowes and neither had the 96" x 48" x 2" sheets. In fact the closest I could come was 96" x 24" x 1.5" and it was the tongue in groove type. I bought a couple sheets and some liquid nails to glue them together. Once I did this I measured and realized that once I cut the extra tongue material off each end I would be left with a 96" x 44" x 1.5" sheet. This completely threw off the measurements in the construction directions since both the width and thickness were different.

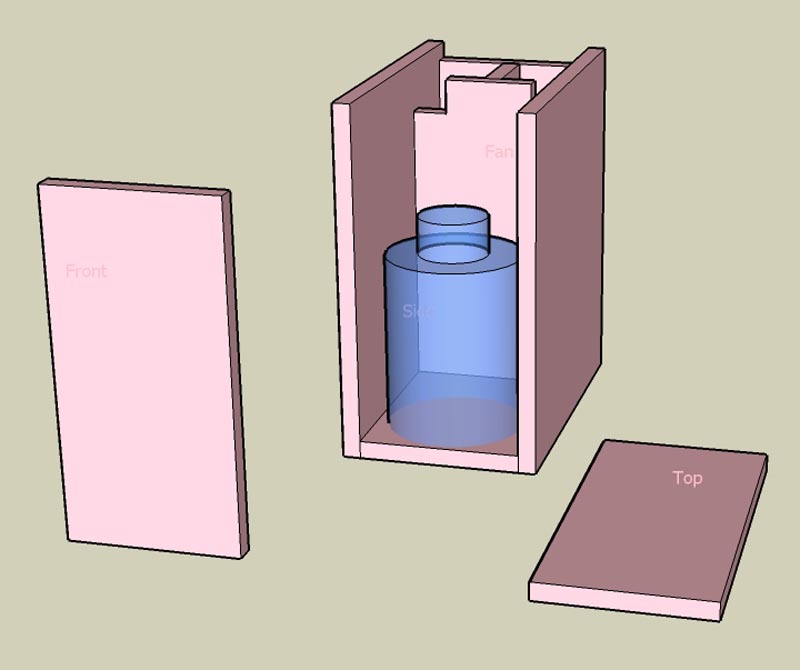

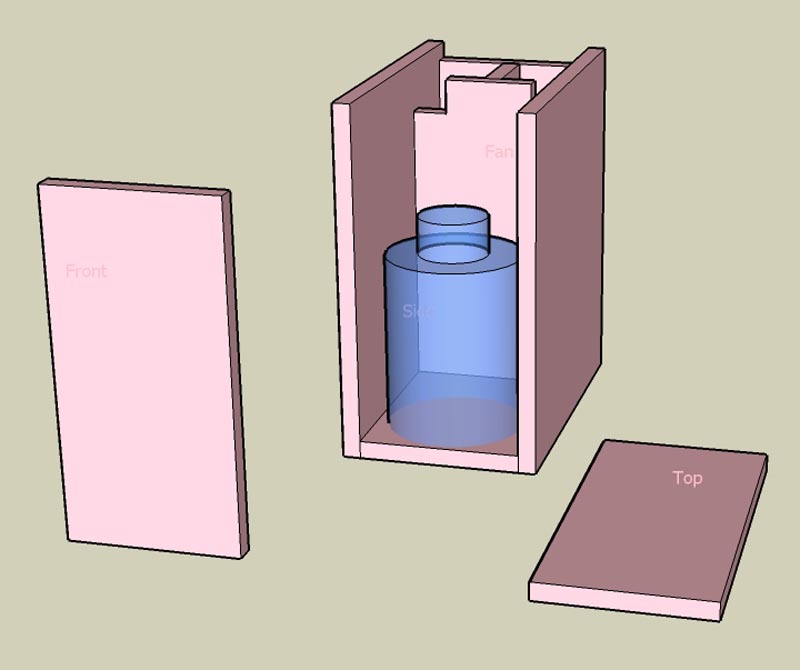

I sketched up some plans, but was afraid I was going to miss something and because I was cutting the dimensions so close I wanted a proof of concept. So in came Google SketchUp. Really cool program and pretty easy to learn, I put it all in there and came up with some plans and it all worked like a charm. I figured I would share the plans in case anyone else gets stuck in the same situation as me and needs to use the narrower and thinner insulation from HD.

Sheet with cutting lines and dimensions:

Put together in SketchUP: (carboy width and height matches 6.5 gallon)

Chiller in basement keeping a carboy cool:

Pale Ale fermenting at 67 degrees:

I didn't put in the fan and intake squares I cut out in the main sheet since someone may want to use a different size fan. I also cut some quarter round with some foam insulation as per the original directions but modified for my new dimensions. I caulked the seems (ran out and used liquid glue to make that nasty streak on the middle partition.

Hopefully these plans can help someone else out there! I have been very pleased with it's operation and the back can still hold 4 1-gallon milk jugs (Although I don't like to stack them so I only use 2, plus 2 liter bottles are better and last longer) If anyone wants the SketchUp files just let shoot me a PM.

I went to Home Depot and Lowes and neither had the 96" x 48" x 2" sheets. In fact the closest I could come was 96" x 24" x 1.5" and it was the tongue in groove type. I bought a couple sheets and some liquid nails to glue them together. Once I did this I measured and realized that once I cut the extra tongue material off each end I would be left with a 96" x 44" x 1.5" sheet. This completely threw off the measurements in the construction directions since both the width and thickness were different.

I sketched up some plans, but was afraid I was going to miss something and because I was cutting the dimensions so close I wanted a proof of concept. So in came Google SketchUp. Really cool program and pretty easy to learn, I put it all in there and came up with some plans and it all worked like a charm. I figured I would share the plans in case anyone else gets stuck in the same situation as me and needs to use the narrower and thinner insulation from HD.

Sheet with cutting lines and dimensions:

Put together in SketchUP: (carboy width and height matches 6.5 gallon)

Chiller in basement keeping a carboy cool:

Pale Ale fermenting at 67 degrees:

I didn't put in the fan and intake squares I cut out in the main sheet since someone may want to use a different size fan. I also cut some quarter round with some foam insulation as per the original directions but modified for my new dimensions. I caulked the seems (ran out and used liquid glue to make that nasty streak on the middle partition.

Hopefully these plans can help someone else out there! I have been very pleased with it's operation and the back can still hold 4 1-gallon milk jugs (Although I don't like to stack them so I only use 2, plus 2 liter bottles are better and last longer) If anyone wants the SketchUp files just let shoot me a PM.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)