ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

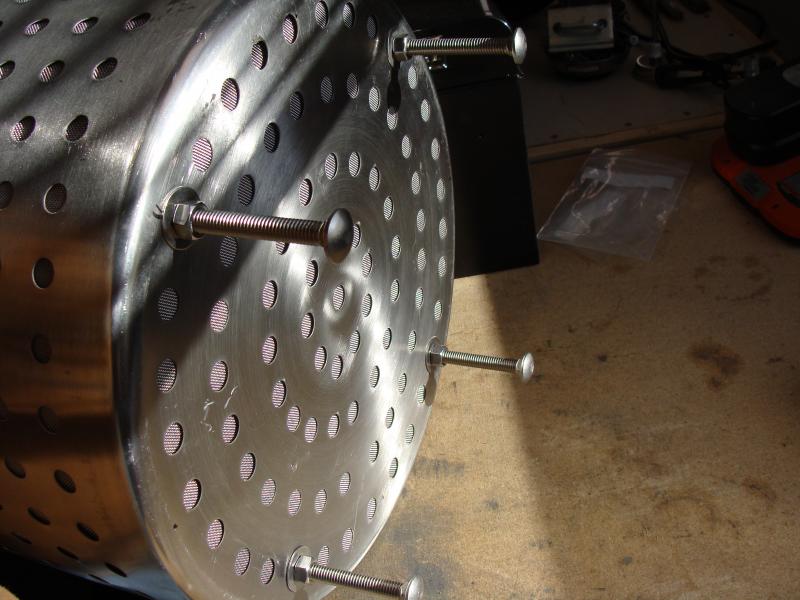

Funny you might ask  I got more fittings for the chiller and attached tubing in a few places. I used stainless flex line for the water supply for extra bling....what you're looking at is the filter canister in front of the chiller, where the filter output is a SS pipe laid across the chiller body split with a 3 way valve and the lines bend back to the chiller water input. There's still a few more triclovers to buy, as well as some electronics...but the end is in sight

I got more fittings for the chiller and attached tubing in a few places. I used stainless flex line for the water supply for extra bling....what you're looking at is the filter canister in front of the chiller, where the filter output is a SS pipe laid across the chiller body split with a 3 way valve and the lines bend back to the chiller water input. There's still a few more triclovers to buy, as well as some electronics...but the end is in sight

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)