ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

I got the 1" FPT x 1.5" Triclover at St. Pat's....as well as the sightglass. I was worried, but I had a seamless transaction...so no complaints here

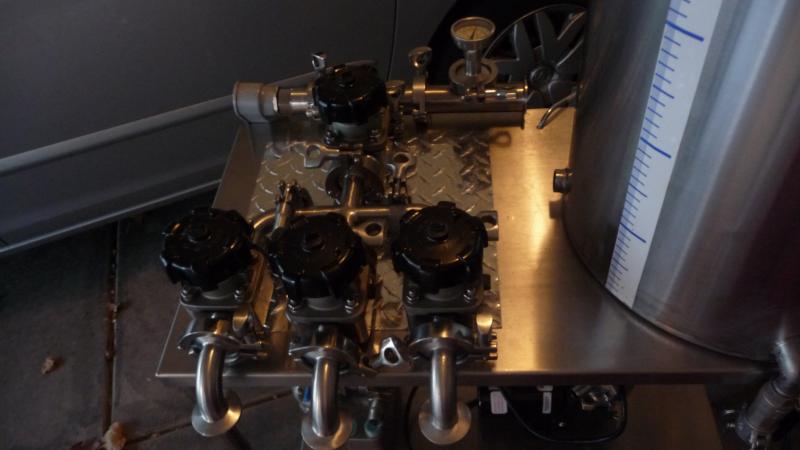

KLG Stainless has by far the best prices, but selection is somewhat limited....so I got all my elbows, clamps etc. from them and went elsewhere for the odds and ends.

I haven't wired anything yet, but I'll probably solder a lug onto the element's TC fitting. That way I can pull the element out in one piece without disconnecting wiring.

Question....I will properly ground the toolbox and everything that connects to it...but how should I ground the stand? I want the rig to be able to roll freely....

KLG Stainless has by far the best prices, but selection is somewhat limited....so I got all my elbows, clamps etc. from them and went elsewhere for the odds and ends.

I haven't wired anything yet, but I'll probably solder a lug onto the element's TC fitting. That way I can pull the element out in one piece without disconnecting wiring.

Question....I will properly ground the toolbox and everything that connects to it...but how should I ground the stand? I want the rig to be able to roll freely....

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)