Mountainsax

Well-Known Member

First, thanks to everyone that has posted their DIY builds. Great work and lots of ideas have been stolen!!

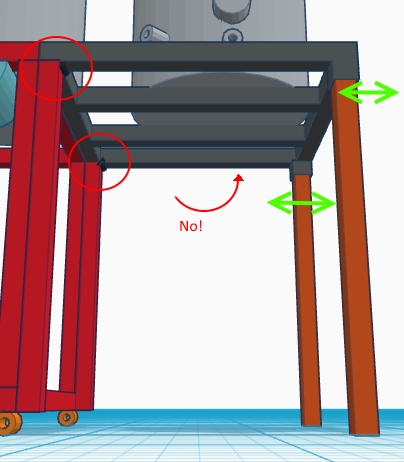

I am hoping to build a 10-15 gallon all grain system after the first of the year. I thought I would put up these conceptual drawings of the brew stand. I would like to go electric, so you can see that I haven't accounted for burners. Hopefully it will give someone some good ideas.

Stand must haves:

- fit 3 15.5 gal keggles

- fit into 2 ft x 3 ft space for storage

- keggles fit underneath for storage (currently two fit underneath, one on top)

- some work space

Expanded Rig

Rig with sides folded

I am hoping to build a 10-15 gallon all grain system after the first of the year. I thought I would put up these conceptual drawings of the brew stand. I would like to go electric, so you can see that I haven't accounted for burners. Hopefully it will give someone some good ideas.

Stand must haves:

- fit 3 15.5 gal keggles

- fit into 2 ft x 3 ft space for storage

- keggles fit underneath for storage (currently two fit underneath, one on top)

- some work space

Expanded Rig

Rig with sides folded

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)