mattman7000

Member

Hello Everyone!

I'm fairly new at brewing and trying to get my own version of a simple e-HERMS set up in my garage. It's a small scale set up. My BK is only 5 gal. and has a 120v heating element in it.

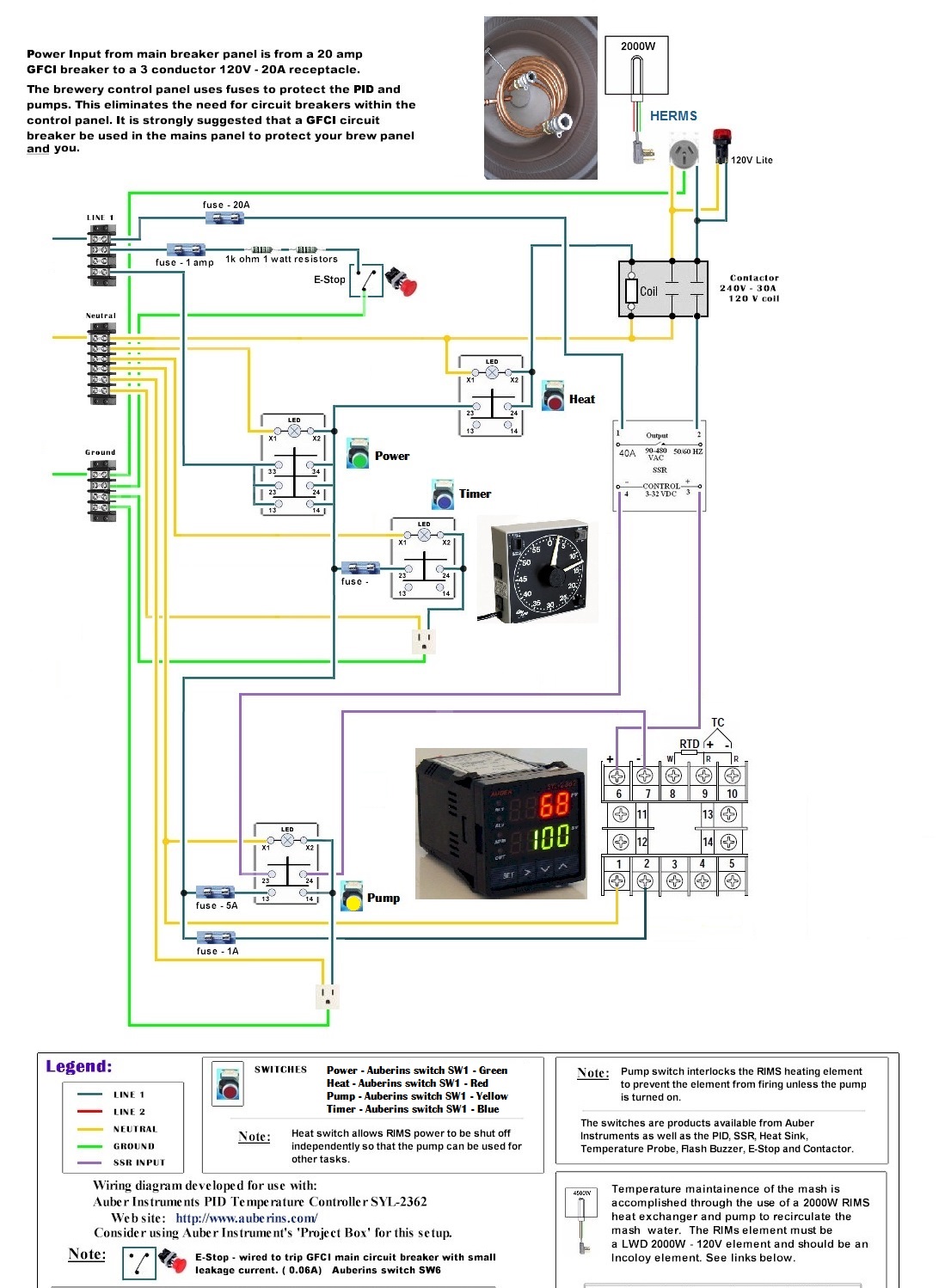

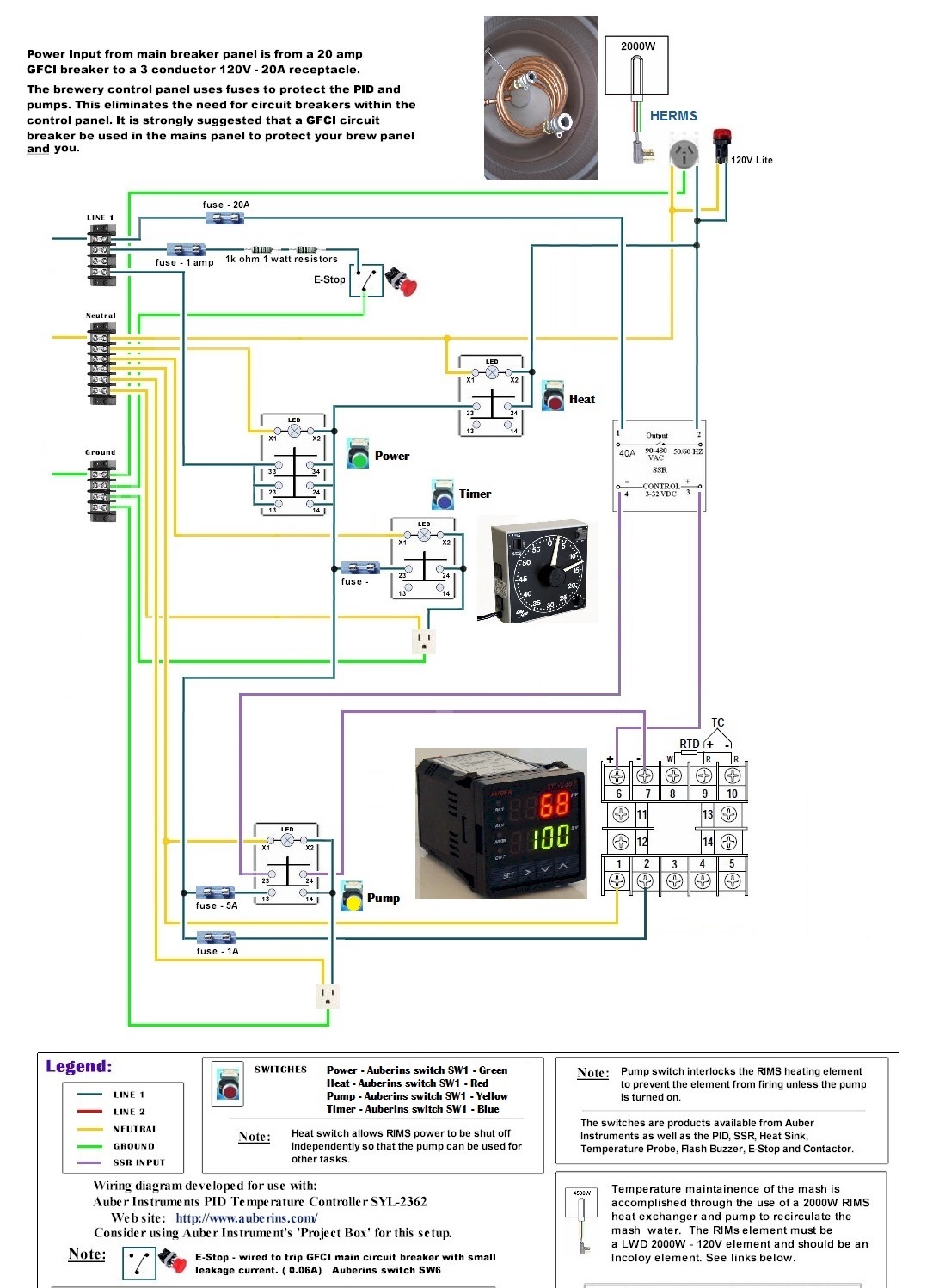

So, I've got almost everything together for this thing, but I'm stuck on the control panel. Like a lot of people here, I got my inspiration for the small set up from jkarp and his Countertop Brutus. I've purchased the same Auber PID, SSR, heat sink, and thermocouple (the 40A like he lists in his parts chart). I've also downloaded the instruction manual from Auber and been all through these forums and the Electric Brewery website. What I'm having trouble with is designing a control panel w/ a little more in the box than just the PID. I like jkarps idea of the 120v switch/plug combo, but wanted to take it a step further by having the plug controlled by an illuminated switch. As I started getting more and more into the forums on how to do this, I've become more and more confused. Essentially what I would like to configure is a simple control panel with a main power illuminated switch, an illuminated switch for an outlet that I can plug my march pump into, a third switch for an outlet I can plug my analog timer into (the timer looks like this one: http://www.ebay.com/itm/GraLab-Dark...446?pt=LH_DefaultDomain_0&hash=item56684e4d06), and a fourth switch for the PID/element. It's probably overkill for a system like mine, but I thought it would be best to try and have all the wiring go to one box instead of trying to run extension cords all over my garage to different outlets. Here is a link to the switches I was thinking about: http://www.auberins.com/index.php?main_page=product_info&cPath=7_32&products_id=223

Anyways, is this all a dumb idea? Would anyone out there be willing to help me figure out how to wire this thing. I'm really new at electric wiring and want to be sure I'm doing everything correctly and safe. I thought about just getting a power strip and plugging everything in there, but I don't know how safe that would be either.

I'm fairly new at brewing and trying to get my own version of a simple e-HERMS set up in my garage. It's a small scale set up. My BK is only 5 gal. and has a 120v heating element in it.

So, I've got almost everything together for this thing, but I'm stuck on the control panel. Like a lot of people here, I got my inspiration for the small set up from jkarp and his Countertop Brutus. I've purchased the same Auber PID, SSR, heat sink, and thermocouple (the 40A like he lists in his parts chart). I've also downloaded the instruction manual from Auber and been all through these forums and the Electric Brewery website. What I'm having trouble with is designing a control panel w/ a little more in the box than just the PID. I like jkarps idea of the 120v switch/plug combo, but wanted to take it a step further by having the plug controlled by an illuminated switch. As I started getting more and more into the forums on how to do this, I've become more and more confused. Essentially what I would like to configure is a simple control panel with a main power illuminated switch, an illuminated switch for an outlet that I can plug my march pump into, a third switch for an outlet I can plug my analog timer into (the timer looks like this one: http://www.ebay.com/itm/GraLab-Dark...446?pt=LH_DefaultDomain_0&hash=item56684e4d06), and a fourth switch for the PID/element. It's probably overkill for a system like mine, but I thought it would be best to try and have all the wiring go to one box instead of trying to run extension cords all over my garage to different outlets. Here is a link to the switches I was thinking about: http://www.auberins.com/index.php?main_page=product_info&cPath=7_32&products_id=223

Anyways, is this all a dumb idea? Would anyone out there be willing to help me figure out how to wire this thing. I'm really new at electric wiring and want to be sure I'm doing everything correctly and safe. I thought about just getting a power strip and plugging everything in there, but I don't know how safe that would be either.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

- back to the main discussion.

- back to the main discussion.