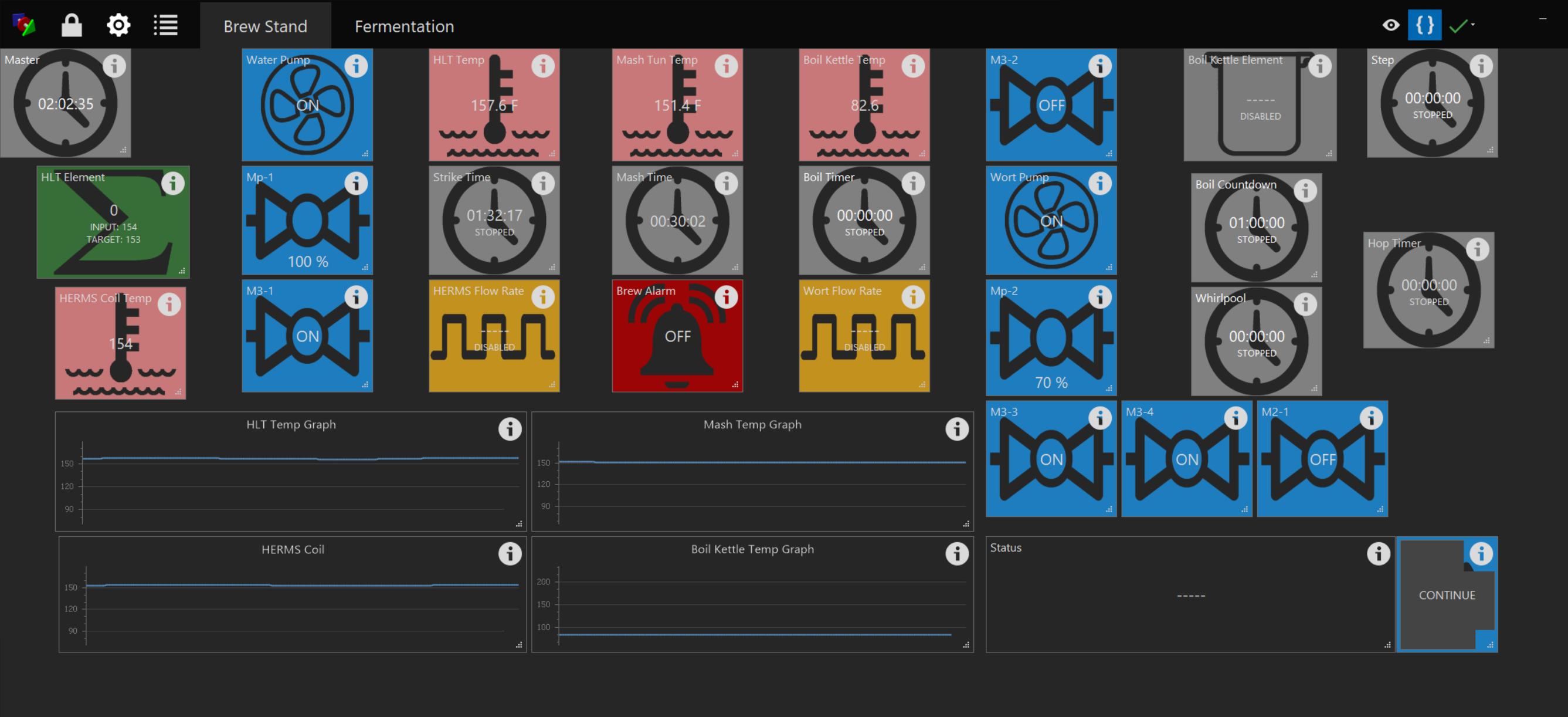

Here's some from my most recent brew done on my all electric setup: A German Pilsner (batch #195). Recipe

here.

The malt (I love this stuff):

Strike water at temperature, just about the mash in:

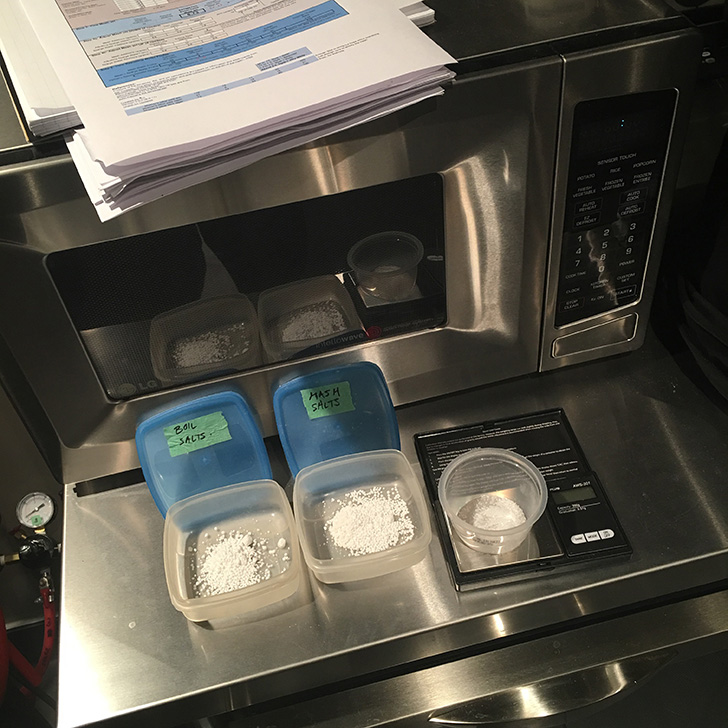

Measuring out salt additions of

gypsum,

calcium chloride, and

Epsom salt:

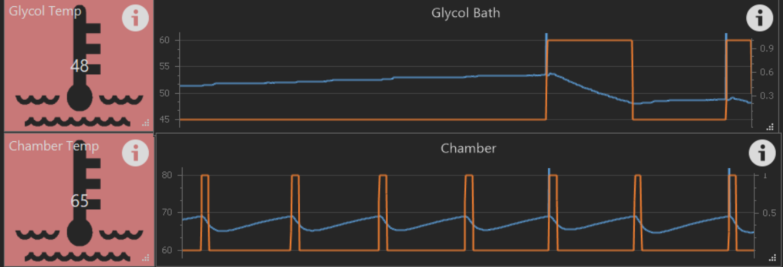

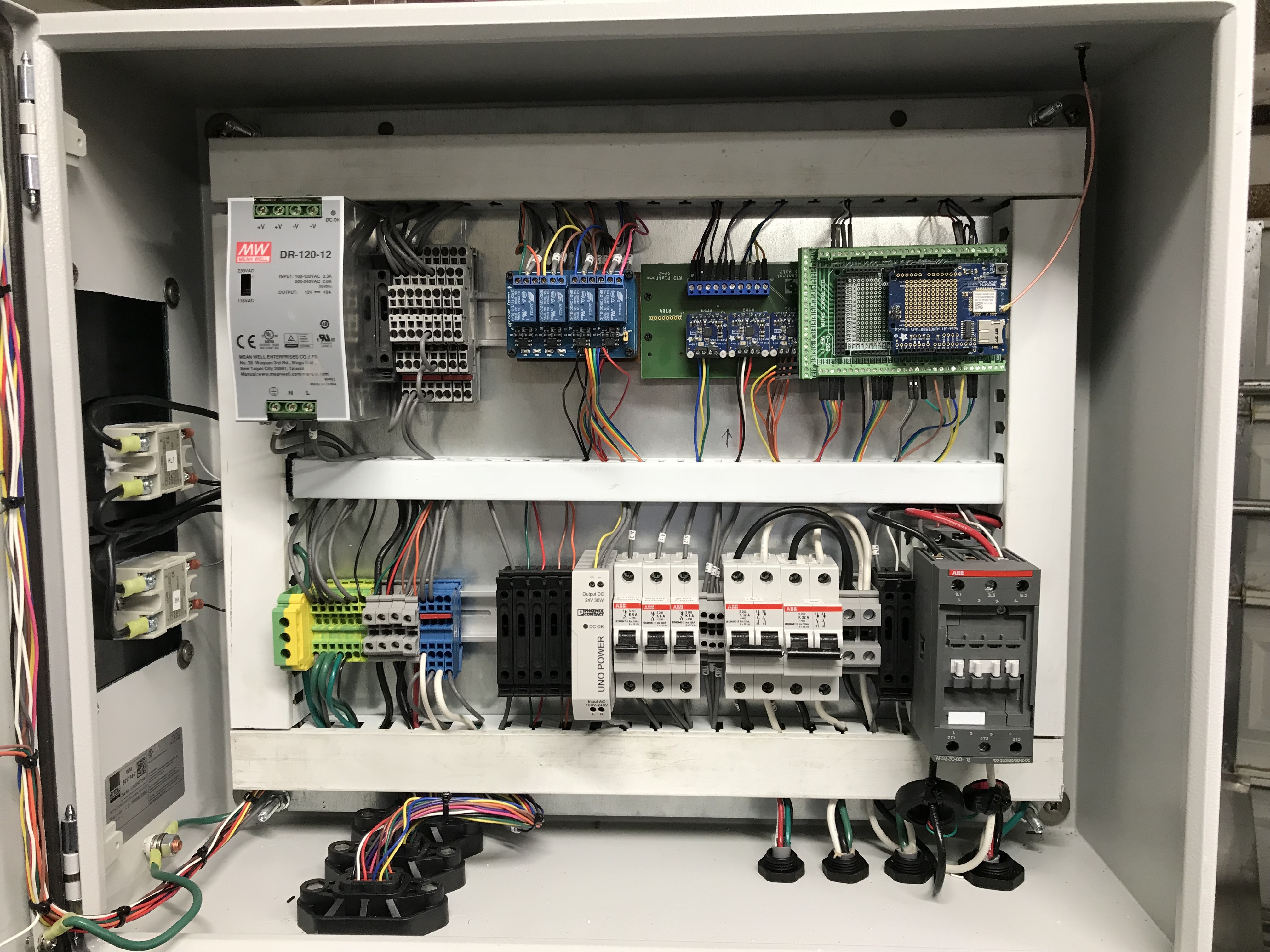

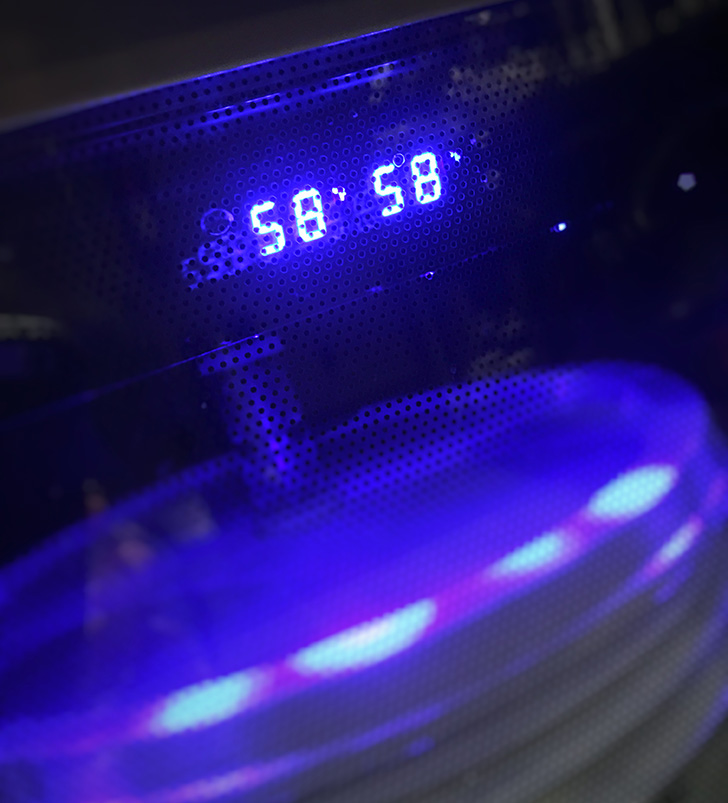

12 gallons of the finished German Pilsner chilling down to ~48F in Danby 45 bottle wine fridges used as fermenting fridges:

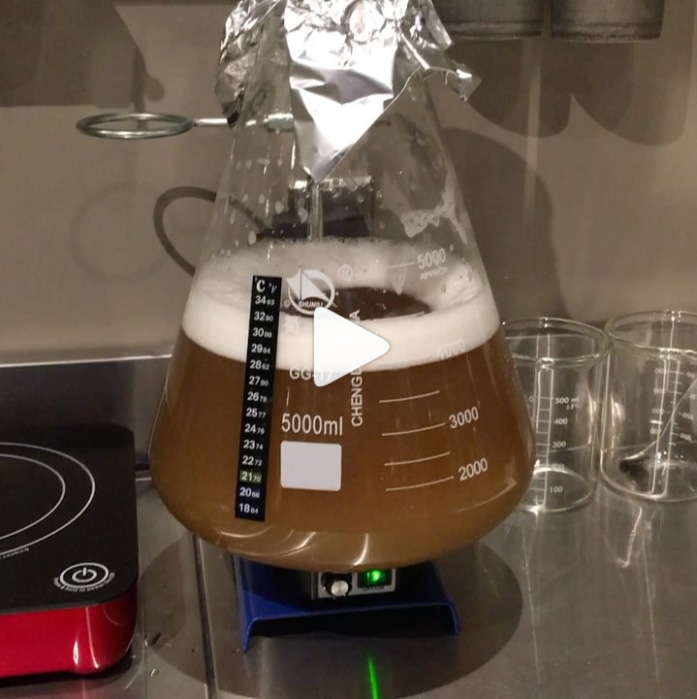

10 days in and fermentation is nearly complete so the temperature is raised ~10F to start the diacetyl rest until fermentation is done (3-7 days):

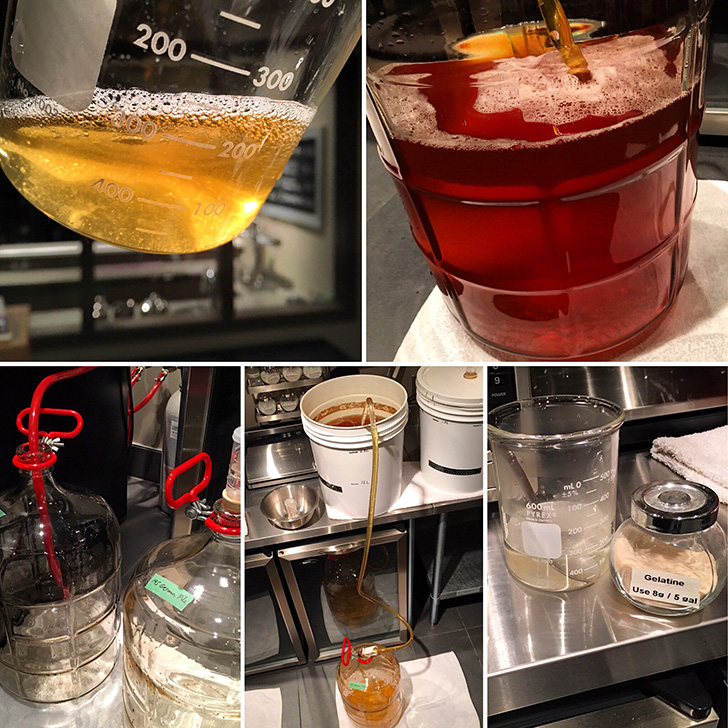

Fermentation done. Beer is racked into CO2 purged 5 gallon glass carboys. Gelatin added to clarify, then kegged ~2 days later:

Beer's now been in the conditioning fridge at ~32F for a week now. I'll leave it for a good month or two and then it should be perfect and look like the beer the recipe was modelled after:

Kal

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)