So after a lot of planning, reading and setup of my brewing space yesterday I went ahead and brew my first batch. This was an extract kit of a Bells Best Brown clone. It asked to brew a grain bag at 160F for 20 min then the regular 1hr brew after adding the extract and later the hops schedule.

So the good: I watched a lot of brew videos and saw a lot of pictures of brewing space setup. With that and without never doing a brew I took many decisions on what table to use, where to locate equipment and where to store hoses and things for brew day. Not rocket science but just wanted to make the brew day process easy. I have to say that the setup worked great and almost all ran smoothly. The brew pot (Brewer’s Edge electric) worked great, the extractor did the job with no condensation, chiller hoses and pumps worked great and I didn’t make any mess nor splashes. Also I didn’t have any boil over and foam was almost none. I used 3 drops of Fermcap to control it.

The nit picky: The chiller I bought seems over board (18” 20 plate). Not a bad problem to have but it cools super fast and I have little time to adjust temperature. With 52.5°F water at input the pump drains the 5gal pot in less than 3min and with the water hose barely open I was able to get the wort out at around 64°F which the guys at my brewing store told me it was ok to pitch with the yeast I was using. Second, the whole process was a one man operation until I put the output hose in the carboy mouth. With the sanitizer it was very slippery and was pulling out. Had to call my wife to hold it. Need a solution for that.

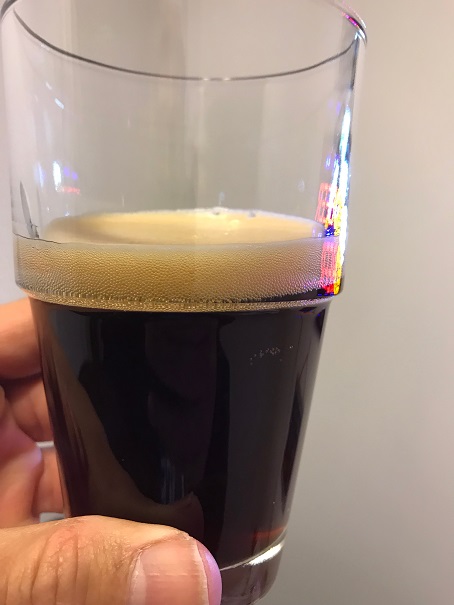

The bad: The hydrometer reading seems to be 1.059 (pic att). I read usually it should be around 1.04 so not sure how bad this is. I started with 5gal of water and at end of boil I had a little above 4gal. They told me to add water at that point if needed to not have too much alcohol. So I forgot and almost drained the kettle. At that point I added near a gallon and then finished draining the kettle. Not sure the impact of this or if the high hydrometer is related to this. Finally, I could see bubbles coming out of air lock as soon as I closed the system. I am controlling the heat with Inkbird setup to 67°-69°F and works perfect. But this morning I saw bubbling stopped. After close inspection seems the airlock (cup style) water level was a tiny too low and was just at the border of the top of the openings (little windows around) of the upside down cup inside. I added a little more water and saw bubbles again.

Now questions: What can you say about my hydrometer reading? Do I need to worry? What about the air lock being maybe a little open for about 12hrs? Is fermentation screwed up? There is like a ¼” foam on top of carboy wort (pic att). Is that low because of the Fermcap? Anything very wrong on what I did?

Final notes: Cleaning the chiller was a pain. I spent maybe 15 times more water doing that than cooling. Tiny parts of hops kept coming out. Is there any good way to filter wort to avoid that?

Thanks a lot and sorry for the long post ;-)

So the good: I watched a lot of brew videos and saw a lot of pictures of brewing space setup. With that and without never doing a brew I took many decisions on what table to use, where to locate equipment and where to store hoses and things for brew day. Not rocket science but just wanted to make the brew day process easy. I have to say that the setup worked great and almost all ran smoothly. The brew pot (Brewer’s Edge electric) worked great, the extractor did the job with no condensation, chiller hoses and pumps worked great and I didn’t make any mess nor splashes. Also I didn’t have any boil over and foam was almost none. I used 3 drops of Fermcap to control it.

The nit picky: The chiller I bought seems over board (18” 20 plate). Not a bad problem to have but it cools super fast and I have little time to adjust temperature. With 52.5°F water at input the pump drains the 5gal pot in less than 3min and with the water hose barely open I was able to get the wort out at around 64°F which the guys at my brewing store told me it was ok to pitch with the yeast I was using. Second, the whole process was a one man operation until I put the output hose in the carboy mouth. With the sanitizer it was very slippery and was pulling out. Had to call my wife to hold it. Need a solution for that.

The bad: The hydrometer reading seems to be 1.059 (pic att). I read usually it should be around 1.04 so not sure how bad this is. I started with 5gal of water and at end of boil I had a little above 4gal. They told me to add water at that point if needed to not have too much alcohol. So I forgot and almost drained the kettle. At that point I added near a gallon and then finished draining the kettle. Not sure the impact of this or if the high hydrometer is related to this. Finally, I could see bubbles coming out of air lock as soon as I closed the system. I am controlling the heat with Inkbird setup to 67°-69°F and works perfect. But this morning I saw bubbling stopped. After close inspection seems the airlock (cup style) water level was a tiny too low and was just at the border of the top of the openings (little windows around) of the upside down cup inside. I added a little more water and saw bubbles again.

Now questions: What can you say about my hydrometer reading? Do I need to worry? What about the air lock being maybe a little open for about 12hrs? Is fermentation screwed up? There is like a ¼” foam on top of carboy wort (pic att). Is that low because of the Fermcap? Anything very wrong on what I did?

Final notes: Cleaning the chiller was a pain. I spent maybe 15 times more water doing that than cooling. Tiny parts of hops kept coming out. Is there any good way to filter wort to avoid that?

Thanks a lot and sorry for the long post ;-)

Last edited: