You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your Kegerator

- Thread starter Flyin' Lion

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

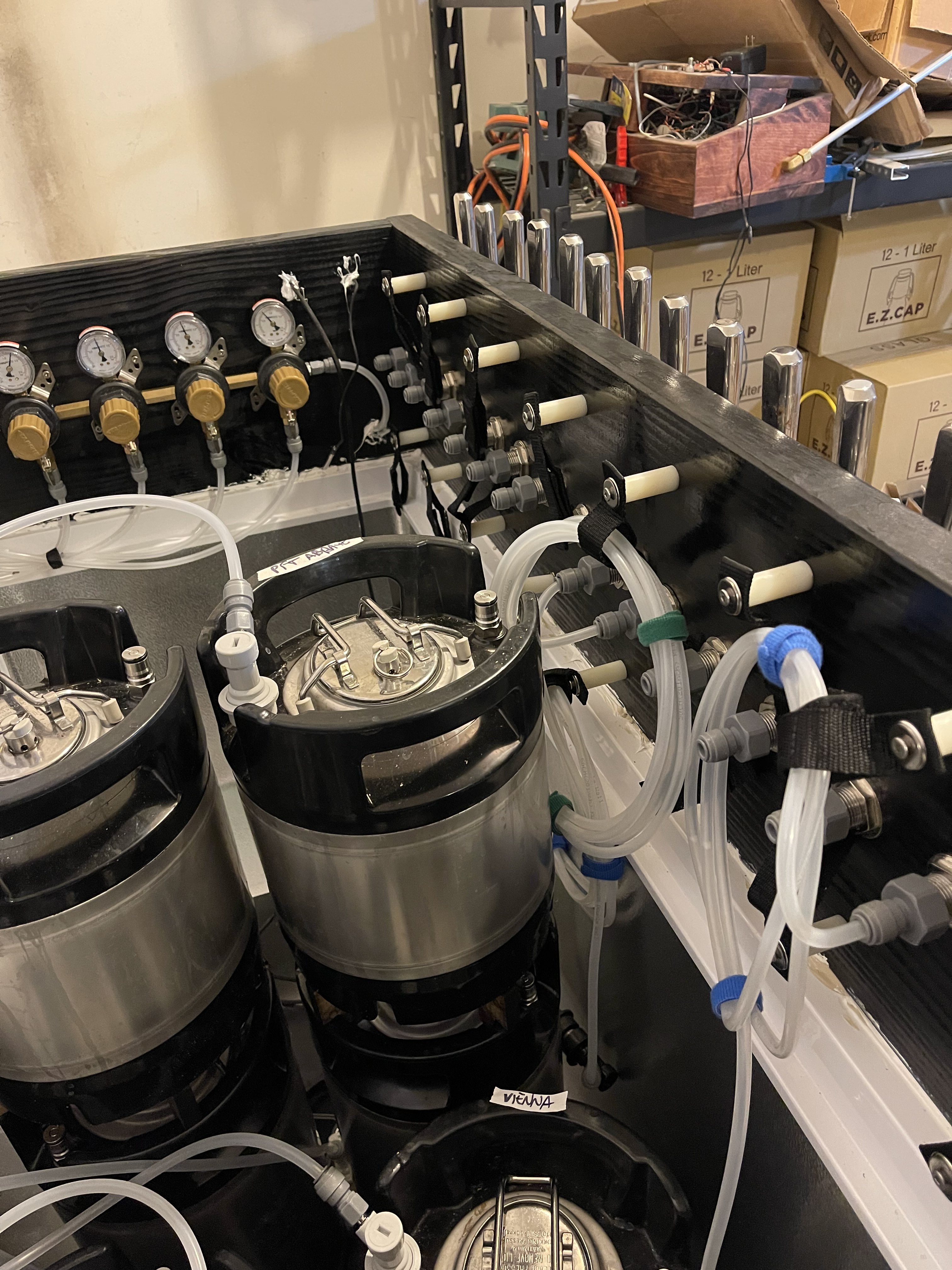

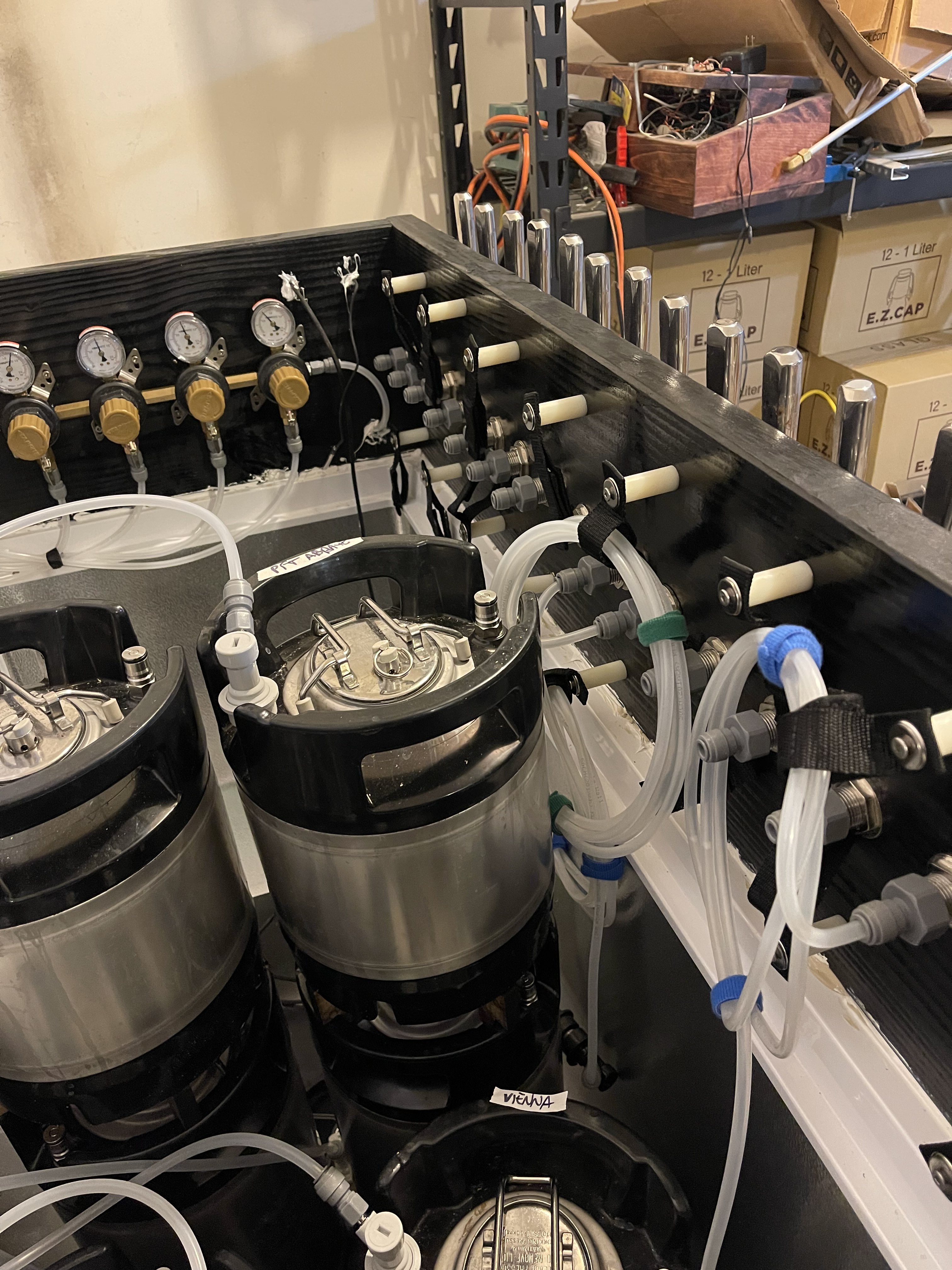

My old keezer has 9 taps. This is not enough, and a second keezer was needed. Clearly, what was called for was overkill.

Here is the new keezer:

It's an Insignia 14.0 cf (NS-CZ14WH2) with 18 taps.

It's pretty much a bog-standard design, with a framing lumber box glued to the top of the freezer. The tap handles are labeled A through R, salt-water etched onto the stainless steel handles (from Amazon):

Inside is all Duotight/EVABarrier (thanks to BrewHardware for stocking regulators and distribution blocks with flare fittings):

There are 5 zones set by secondary regulators, varying carbonation levels for stouts, regular beers, highly carbonated beers, sodas, and still. Here's the other view:

Mountable velcro ties (with grommets) are attached to the front panel with standoffs for neat hose management.

Note the keg-stacking widgets. There can be 8 stacks of two kegs each (one 3 gallon and one 1.75 gallon), plus two single kegs on the compressor, for 18 total.

Finally, the false bottom:

Shown from the top. It's a swiss-cheese-cut plywood platform (can I tell you what a pain it is to cut 140-mm holes in 3/4" plywood with a hole saw and a hand drill?) on ~3" legs. Fans are mounted in three of the holes, the ones on the left and right blowing up, and the one in the center blowing down. The kegs make kind of a natural tunnel for the airflow.

Cooling down now with beer in it. Now for an 18-tap tap list...

Here is the new keezer:

It's an Insignia 14.0 cf (NS-CZ14WH2) with 18 taps.

It's pretty much a bog-standard design, with a framing lumber box glued to the top of the freezer. The tap handles are labeled A through R, salt-water etched onto the stainless steel handles (from Amazon):

Inside is all Duotight/EVABarrier (thanks to BrewHardware for stocking regulators and distribution blocks with flare fittings):

There are 5 zones set by secondary regulators, varying carbonation levels for stouts, regular beers, highly carbonated beers, sodas, and still. Here's the other view:

Mountable velcro ties (with grommets) are attached to the front panel with standoffs for neat hose management.

Note the keg-stacking widgets. There can be 8 stacks of two kegs each (one 3 gallon and one 1.75 gallon), plus two single kegs on the compressor, for 18 total.

Finally, the false bottom:

Shown from the top. It's a swiss-cheese-cut plywood platform (can I tell you what a pain it is to cut 140-mm holes in 3/4" plywood with a hole saw and a hand drill?) on ~3" legs. Fans are mounted in three of the holes, the ones on the left and right blowing up, and the one in the center blowing down. The kegs make kind of a natural tunnel for the airflow.

Cooling down now with beer in it. Now for an 18-tap tap list...

Do you brew 3 gal and 1.75 gal batches? Or do you brew 5 gal and split it between two small kegs? If so, don't you then have the same beer on two taps?

I'm not being a smart a$$, Just curious as to the system you plan on to keep 18 kegs of various sizes full. If the goal is to have 18 taps, all serving beer, then It seems you would need at least 5-10 extra kegs for beer in various stages of conditioning, getting ready to serve. Also a separate fridge would be needed with Co2 capabilities to condition these kegs, or at some point one or several of those taps will be out of service.

Maybe I'm overthinking this, but with 18 taps you are indeed in the 1st World Problem level.

That said, I commend you on your build. Very adventurous.

I'm not being a smart a$$, Just curious as to the system you plan on to keep 18 kegs of various sizes full. If the goal is to have 18 taps, all serving beer, then It seems you would need at least 5-10 extra kegs for beer in various stages of conditioning, getting ready to serve. Also a separate fridge would be needed with Co2 capabilities to condition these kegs, or at some point one or several of those taps will be out of service.

Maybe I'm overthinking this, but with 18 taps you are indeed in the 1st World Problem level.

That said, I commend you on your build. Very adventurous.

No offense taken! This wouldn't work for everyone (or even most everyone), but it's perfect for how I brew (and drink.)

I brew 2.75 and 1.5 gallon batches. I also brew a lot of them -- if we go back into pandemic lockdown, probably 3 batches a week. I do split 2.75s into two batches sometimes, but only if there's a variable I'm exploring: type of yeast or hops, usually, so not only is it not (exactly) the same beer, but I want to be able to side-by-side them on two taps to see the differences.

Some batches get bottled. I'm starting to have 1 L bottles piling up.

At any given point, one or several taps will indeed be out of service when I'm conditioning or carbonating. And 4-6 taps will be reserved for things like ice tea, ice coffee, and soda. Between the two keezers, I'm still hoping to have ~40 gallons of beer on ~20 taps.

The real (first world) problem is that I just don't drink it or give it away as fast as I can make it.

I brew 2.75 and 1.5 gallon batches. I also brew a lot of them -- if we go back into pandemic lockdown, probably 3 batches a week. I do split 2.75s into two batches sometimes, but only if there's a variable I'm exploring: type of yeast or hops, usually, so not only is it not (exactly) the same beer, but I want to be able to side-by-side them on two taps to see the differences.

Some batches get bottled. I'm starting to have 1 L bottles piling up.

At any given point, one or several taps will indeed be out of service when I'm conditioning or carbonating. And 4-6 taps will be reserved for things like ice tea, ice coffee, and soda. Between the two keezers, I'm still hoping to have ~40 gallons of beer on ~20 taps.

The real (first world) problem is that I just don't drink it or give it away as fast as I can make it.

cyberbackpacker

Well-Known Member

The real (first world) problem is that I just don't drink it or give it away as fast as I can make it.

Well I make it to South Bend a few times a year for Football, Basketball, and Hockey so I am happy to help consume when I am in the area!

I understand a bit better now. That may indeed be the solution for all that small brewing. I don't think I could put up with all the cleaning involved. Thats alot of keg cleaning. It would seem that just when you get a beer conditioned properly, the keg blows.

I have a 9 keg system, with 8 in the keggerator, and one waiting, and four fermenters full. When a keg blows, everything moves up one, and its time to brew. However I only have three taps on the three that are conditioned perfectly. I can move them around if I need to lay out a tasting flight, but normally, its just the three. That's about all the work I can handle. Cheers.

I have a 9 keg system, with 8 in the keggerator, and one waiting, and four fermenters full. When a keg blows, everything moves up one, and its time to brew. However I only have three taps on the three that are conditioned perfectly. I can move them around if I need to lay out a tasting flight, but normally, its just the three. That's about all the work I can handle. Cheers.

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

Next project: A 6’ long drip tray!

codysorgenfrey

Well-Known Member

Just finished my first keezer build!

I see three taps. Do you have room for three kegs? Looks tight, especialy with the Co2 cylinder in there. Nice build. Should dispense beer alright.

codysorgenfrey

Well-Known Member

Yeah it’ll hold a 3rd on the right side where the CO2 tank is. Just have to move things around to get it all to fit. It’s super tight.I see three taps. Do you have room for three kegs? Looks tight, especialy with the Co2 cylinder in there. Nice build. Should dispense beer alright.

JeffersonStateBrewing

Well-Known Member

- Joined

- May 23, 2021

- Messages

- 106

- Reaction score

- 50

Next project: A 6’ long drip tray!

Keep us informed! I too need to build a 6 foot drip tray. I have an idea HOW to build it, I just don't have the time or tools to do it right now. I would be curious to see what you have planned.

NickTheGreat

Well-Known Member

- Joined

- Apr 17, 2012

- Messages

- 1,291

- Reaction score

- 531

I finally put a drip tray on mine. Found a cheap one and found a scrap piece of plywood that was the exact size as needed. I will get a proper piece of wood and stain it to look nicer. I mean, I probably won't just leave it like this . . .

"There is nothing as permanent as a temporary solution".I finally put a drip tray on mine. Found a cheap one and found a scrap piece of plywood that was the exact size as needed. I will get a proper piece of wood and stain it to look nicer. I mean, I probably won't just leave it like this . . .

A quote from somebody famous, I'm sure.

And it looks like somebody stole one of your faucets!

@NickTheGreat, maybe you can find a scrap piece of plastic to protect your drip-tray support. Properly stained or otherwise, it would soon be in trouble under my drip tray -- I'm kinda messy, and besides, drips happen.

KookyBrewsky

Well-Known Member

- Joined

- Feb 23, 2020

- Messages

- 363

- Reaction score

- 121

I haven't brewed in almost a year now because I was tired of bottling but I'm also cheap and was waiting for a deal....

I scored this bundle for $125 through OfferUp.

Came with Kegerator, Miller Lite handle, two CO2 tanks, and quite a few extras like spare parts and cleaning supplies.

I do have a few questions though. First, on the Draught Technologies (who seemingly has no website even though it's made in the USA) has a hole in it. From what I can tell every regulator I see online has a hole in a similar place but they don't look as funky as mine. Does it seem alright? Second, there's a tiny gash inside. I figured it doesn't look like it hit anything important, nothing seems to be leaking, and it keeps temperature as I bought it when it was still running, ice cold at 34F. So I ordered some JB-Weld KwikWeld. Can anyone confirm that the location of the gash is benign and I can simply patch it up with this $5 epoxy?

If this is the case, I basically stole this bundle. Truly unreal. I have 2 used kegs on the way from AIH that I got for $45 each I think. Now I just have to order from Spike the closed transfer/carbonation bundle and I'm off to the races.

First brew day in about a year in 2 days once my yeast starter is going... I guess in the downtime I played with, and still play with, sourdough bread. I know a bit more about yeast and I'm switching to all organic beer. It's an early Christmas!

I scored this bundle for $125 through OfferUp.

Came with Kegerator, Miller Lite handle, two CO2 tanks, and quite a few extras like spare parts and cleaning supplies.

I do have a few questions though. First, on the Draught Technologies (who seemingly has no website even though it's made in the USA) has a hole in it. From what I can tell every regulator I see online has a hole in a similar place but they don't look as funky as mine. Does it seem alright? Second, there's a tiny gash inside. I figured it doesn't look like it hit anything important, nothing seems to be leaking, and it keeps temperature as I bought it when it was still running, ice cold at 34F. So I ordered some JB-Weld KwikWeld. Can anyone confirm that the location of the gash is benign and I can simply patch it up with this $5 epoxy?

If this is the case, I basically stole this bundle. Truly unreal. I have 2 used kegs on the way from AIH that I got for $45 each I think. Now I just have to order from Spike the closed transfer/carbonation bundle and I'm off to the races.

First brew day in about a year in 2 days once my yeast starter is going... I guess in the downtime I played with, and still play with, sourdough bread. I know a bit more about yeast and I'm switching to all organic beer. It's an early Christmas!

Last edited:

I do have a few questions though. First, on the Draught Technologies (who seemingly has no website even though it's made in the USA) has a hole in it. From what I can tell every regulator I see online has a hole in a similar place but they don't look as funky as mine. Does it seem alright?

This is the vent hole. Looks like yours has some excess paint/powder coat covering a bit of it. You could clean this up a bit using a small knife or drill bit while holding the regulator with the hole facing down.

Second, there's a tiny gash inside. I figured it doesn't look like it hit anything important, nothing seems to be leaking, and it keeps temperature as I bought it when it was still running, ice cold at 34F. So I ordered some JB-Weld KwikWeld. Can anyone confirm that the location of the gash is benign and I can simply patch it up with this $5 epoxy?

This appears to just be the inside plastic body panel. The hole above it is where the condensation from the evaporator in the back drains to. Patching it up shouldn't be a problem.

KookyBrewsky

Well-Known Member

- Joined

- Feb 23, 2020

- Messages

- 363

- Reaction score

- 121

This is the vent hole. Looks like yours has some excess paint/powder coat covering a bit of it. You could clean this up a bit using a small knife or drill bit while holding the regulator with the hole facing down.

This appears to just be the inside plastic body panel. The hole above it is where the condensation from the evaporator in the back drains to. Patching it up shouldn't be a problem.

Amazing, that's what I gathered from research but wanted to ask for more opinions. Going to patch it up tonight. $125 to both keep me brewing and give me the best possible experience. Doesn't get much better than that. Haven't been this excited in a while. Instead of 50 bottles and still managing to get infections, I can clean a gigantic bottle very well and have carbonated beer in 24 hours. I just have to clean the garage a bit, it''ll stay there so I can share with the neighbors.

okwesbrewing

Member

- Joined

- May 1, 2020

- Messages

- 15

- Reaction score

- 65

Christmas came early. Got the collar on a couple weeks ago and had some delays getting all of the parts and pieces in. Have a cider fermenting in it right now and as soon as I pull it out I'll drop in all of the beer and gas lines.

Looks great, really clean build. If you want to add a drip tray without spending a lot, check out my plywood and iron pipe support setup. The drip tray was ~$20 online, I'll dig up a link. No screws are used to attach it to the collar, the shanks act as bolts to secure it in place. If I had it to do over, I would have painted the entire plywood piece with chalkboard paint.

Last edited:

Love the all black taps, where did you get those?Christmas came early. Got the collar on a couple weeks ago and had some delays getting all of the parts and pieces in. Have a cider fermenting in it right now and as soon as I pull it out I'll drop in all of the beer and gas lines.View attachment 750707View attachment 750708

DuncB

Well-Known Member

Looks great, I have the same model freezer which I intended to convert to keezer before lockdown but then it got snaffled for food. I stole about 20 percent for hops though.

Had to convert this beast instead, takes 8 kegs.

Sadly black nukataps weren't available when I built this, they would have looked great.

The Stout on nitro tap is on the other side.

Had to convert this beast instead, takes 8 kegs.

Sadly black nukataps weren't available when I built this, they would have looked great.

The Stout on nitro tap is on the other side.

okwesbrewing

Member

- Joined

- May 1, 2020

- Messages

- 15

- Reaction score

- 65

A drip tray has been on the list to figure out. That looks neat and something I will keep in mind.Looks great, really clean build. If you want to add a drip tray without spending a lot, check out my plywood and iron pipe support setup. The drip tray was ~$20 online, I'll dig up a link. No screws are used to attach it to the collar, the shanks act as bolts to secure it in place. If I had it to do over, I would have painted the entire plywood piece with chalkboard paint.

Nukatap Stealth Bombers. I think they are technically discontinuing those in favor of the Punisher color combo. Got mine through Keg Factory but anywhere that carries Kegland stuff should have them.Love the all black taps, where did you get those?

And found the pic where I was seeing how the kegs would fit in there.

My New Year's project. Thanks to everyone for the inspiration. I'm looking forward to never having to bottle again.

Dan

Dan

- Joined

- Aug 12, 2013

- Messages

- 2,066

- Reaction score

- 2,729

My kegerator is a simple frame with 6 taps that works well, but man…. I wish I could make something that looks as cool as that!My New Year's project. Thanks to everyone for the inspiration. I'm looking forward to never having to bottle again.

Dan

View attachment 756411View attachment 756412

Great job!

Haven't been this excited in a while. Instead of 50 bottles and still managing to get infections, I can clean a gigantic bottle very well and have carbonated beer in 24 hours.

While technically you can force carbonate quicker with a high pressure over a shorter time, you still have to get the beer to a cold temp for this to happen, and that requires some time. Then, on a high pressure the keg needs to be rolled or otherwise agitated to speed this process up, and although you have some level of carbonation, Its not necessarily the best beer.

Setting the CO2 to serving pressure, getting the keg cold and leaving it alone for a couple of weeks at least gives the best results. The keg can settle out the fine particulate mater and the beer is carbonated perfectly.

I realize that with your first keg, you're anxious to try it, so knock yourself out, but if good beer on demand is what you want, you got to start thinking "Pipeline"

If you have room for two kegs in the keggerator you need at least three kegs. One serving, one cold conditioning and carbing up, and one full, waiting to go in. You then need your fermenter full, and waiting, so when the keg blows, the second goes on tap, the third goes in the cold and starts conditioning, and the first is filled to free up the fermenter. Now its time to brew. This process works regardless of your capacity. If the keggerator holds four kegs, you need at least five.

With this process, once the pipeline is full and functional, you don't brew any more than you normally would. You just have a lot more beer on hand than 50 bottles.

I'm not trying to discourage you, just letting you know you are leaving all your old problems (bottling) for a whole set of new ones. Enjoy the journey. Cheers.

While technically you can force carbonate quicker with a high pressure over a shorter time, you still have to get the beer to a cold temp for this to happen, and that requires some time. Then, on a high pressure the keg needs to be rolled or otherwise agitated to speed this process up, and although you have some level of carbonation, Its not necessarily the best beer.[...]

Beer does not have to be "cold" for a fast carbonation scheme to work, nor is shaking required. It is simply a pressure vs temperature problem that can be solved with higher pressure for higher temperatures...

Cheers!

Ok, well nevermindBeer does not have to be "cold" for a fast carbonation scheme to work, nor is shaking required. It is simply a pressure vs temperature problem that can be solved with higher pressure for higher temperatures...

Cheers!

SLOPES

New Member

- Joined

- Jan 16, 2022

- Messages

- 2

- Reaction score

- 10

Boy o Boy, some of these builds are absolutely next level.

I am a new Brewer and new the forum (thanks for having me).

I built my first ever kegerator last week. Here are some pictures!

The batch in this keg is a SMASH West Coast IPA with cascade hops. Its absolutely delicious.

NOTE: I have a 5lb bottle that I will be utilizing to get my second keg in there, don't stress.

I am a new Brewer and new the forum (thanks for having me).

I built my first ever kegerator last week. Here are some pictures!

The batch in this keg is a SMASH West Coast IPA with cascade hops. Its absolutely delicious.

NOTE: I have a 5lb bottle that I will be utilizing to get my second keg in there, don't stress.

Attachments

Similar threads

- Replies

- 23

- Views

- 1K

- Replies

- 25

- Views

- 1K

- Replies

- 2

- Views

- 288

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)