BeerBrewBob

Active Member

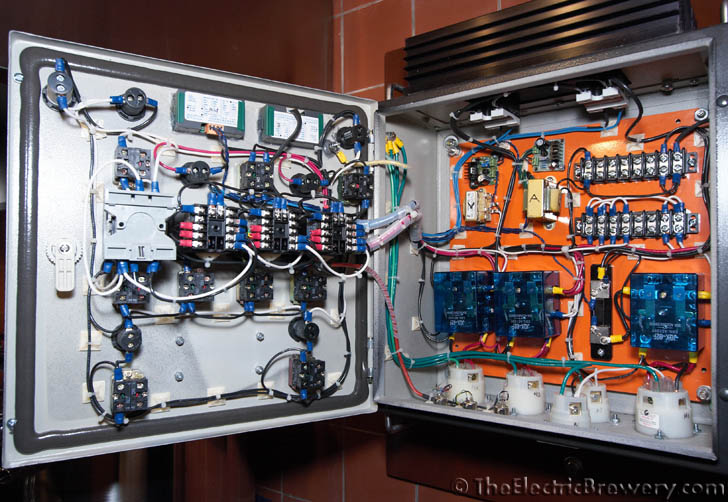

Ok, just one teaser picture with my panel wide open (being the **** I am)...

I'm working on writeup for this portion of the site now...

Kal

I am late to the show, however, I cam across this thread with the intent of starting my own project....After Kal's post, I no longer saw a need to continue past page 2. Geeze.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

![20170423_133339[1].jpg 20170423_133339[1].jpg](https://cdn.homebrewtalk.com/data/attach/344/344149-20170423-133339-1-.jpg)

![20170405_122504[1].jpg 20170405_122504[1].jpg](https://cdn.homebrewtalk.com/data/attach/344/344151-20170405-122504-1-.jpg)

![20170430_113558[1].jpg 20170430_113558[1].jpg](https://cdn.homebrewtalk.com/data/attach/344/344152-20170430-113558-1-.jpg)

![IMG-20170326-WA0010[1].jpg IMG-20170326-WA0010[1].jpg](https://cdn.homebrewtalk.com/data/attach/344/344153-IMG-20170326-WA0010-1-.jpg)