Dynachrome

Well-Known Member

I am doing this one again tonight. I have a 31-1/2lb grain bill this time.

I'm curious why the high mash temp. I know you stated you wanted a deeper red color, but that could be easily achieved by adding a pound of higher L crystal and a 90 min boil. Typically mash outs are done at 165-168 because all enzyme conversation stops at those temps. What was your sparge temp?

I might also suggest a wort chiller so you don't have to chill your wort on the back deck.

Scalded Dog IPA - Escahts says to shoot for 52 IBUs.

25.5 lbs 2 row malted

3.5 lb Cara Pils #1

1 lbs Bonlander Munich Malt (Briess Malt #5344)

1 lbs Special Roast Malt (Breiss Malt #5398)

____________________

31 lbs total grain bill

18 gallons water - yielded approximately 15-1/2 gallons of wort post-boil.

--------------------------------

Warmed up the mashtun before mashing in.

4 gallons @ 166F

4 gallons @ 182F

...leveled off at 156F and then crept up to 158F - 60 minute mash

The temperature held well this method.

4 gallons @167F 10 minutes

drain

4 gallons @167F 10 minutes

drain

2 gallons @160F to complete drain

47.5ABU calculated "Way Hoppy".

2.0 oz 13.90 AA Chinook pellet @60 minutes

2.0 oz 3.20 AA Cascade pellet @60 minutes

1.0 oz 3.20 AA Cascade pellet @15 minutes

1.0 oz 6.90 AA Cascade pellet @15 minutes

2.0 oz 7.00 AA Cascade whole leaf dry @3 minutes

1.0 oz 4.00 AA Cascade whole leaf dry @3 minutes

Wort was left to cool on the back deck.

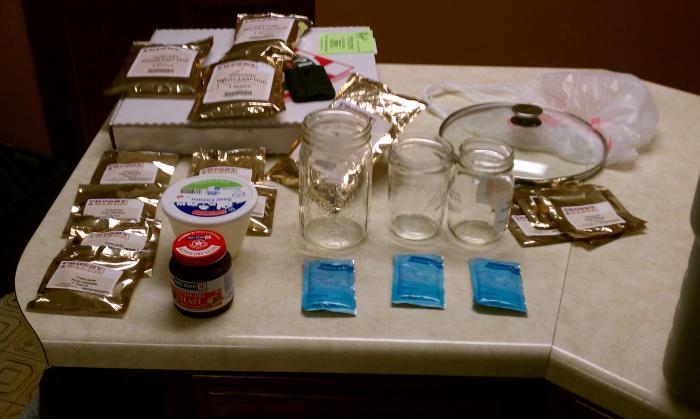

Made (3) s-04 dry yeast rehydrations to pitch in the morning.

I am also going to ferment about 2-1/2 gallons of this with Fleishman's bakers yeast as a test.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I fermented two of these in pots. They were at 1.010. I bottled them both.

There is another portion of it in a carboy.

I'm going to let that one finish a little more before I bottle it.

I'm stranded in the great frozen north about four hours from home.

I went and picked up two bottles of Two Hearted. It is way hoppier than what I brewed. It is also lighter mouth feel. Go figure. I thought I doubled up on hops to match the double recipe, plus additional for the dry leaf hops. I'll have to check my math.

BUT- after the Alpha-amylase breaks it down then the Beta-amylase acts on it.Isn't 72C (~162F) the very highest you'll ever want to go, in order to have Alpha-amylase convert some of the most stubborn starch?

BUT- after the Alpha-amylase breaks it down then the Beta-amylase acts on it.

At 162 you've basically denatured ALL the enzymes as Yooper said.

Also, I think in addition to too much crystal you should consider Centennial in your hop schedule.

That's because lower temperature mashes (131-150) favor beta amylase. A higher mash temp (154-164) favors alpha amylase, which will produce a "thicker" bodied beer.