Here's just one example of a setup you might consider. I can do either 5- or 10-gallon brews with this. I have both 10- and 20-gallon kettles I can swap out as necessary. They're interchangeable in connections, valves, boil element, etc. except for the capacity.

I have a quasi-3 vessel system that I use analogously to a BIAB system--that is, single infusion in the mash tun, just like if it were BIAB, but I also recirculate through a RIMS.

What makes it quasi-3 vessel? I have a BK in which I heat the strike water (Vessel 1), the mash tun (Vessel 2), and a RIMS tube to manage heat with the recirculation ("Vessel" 3).

The advantages to this approach, if you're doing single infusion, is that you don't need a 3rd vessel and the space required for it plus probably a HERMS setup.

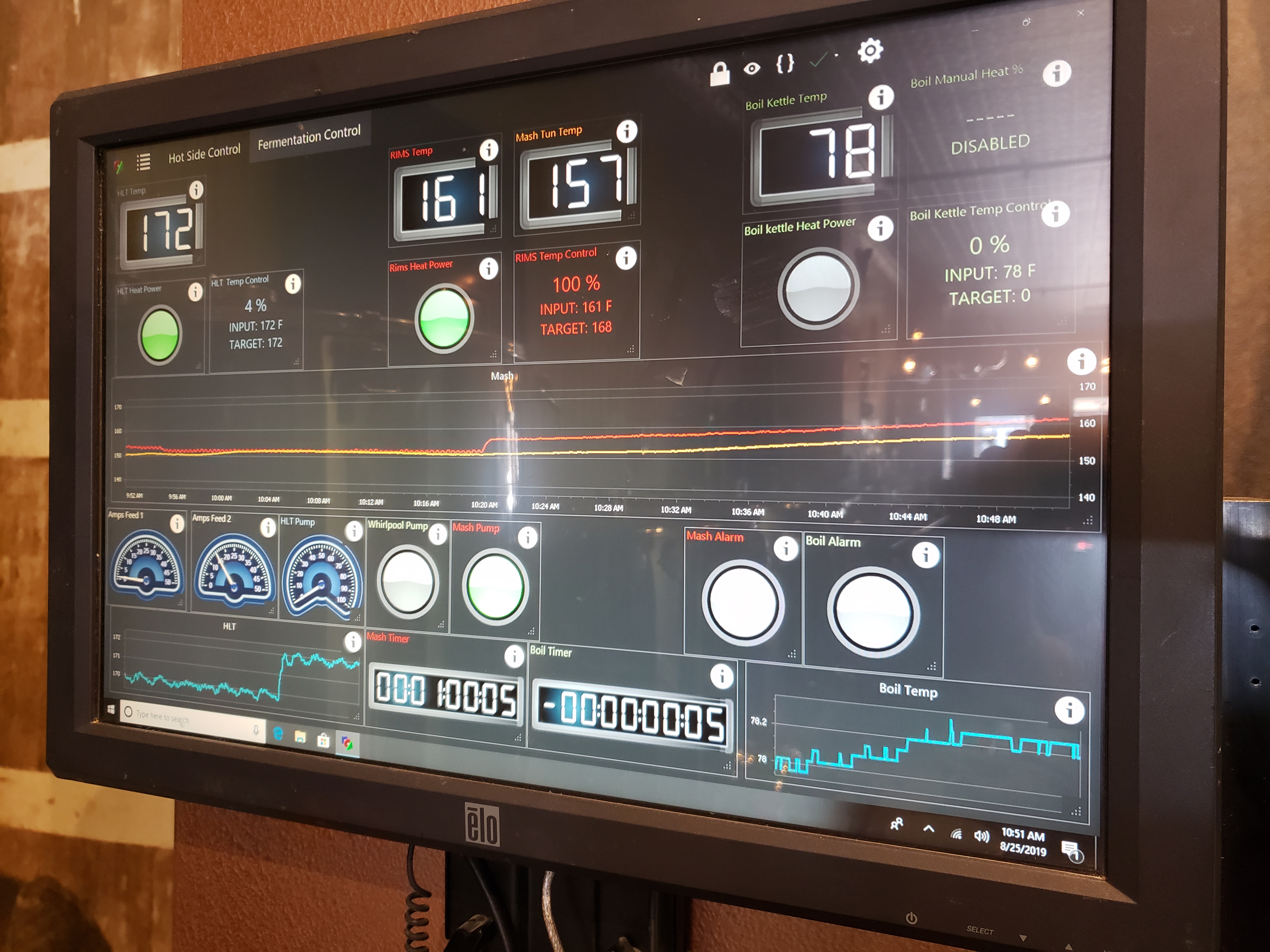

Now, I decided to get a panel for the BK and it has an EZBoil in it which allows me to control power percentage during the boil from 0-100 percent at the turn of a small knob. I decided that rather than trying to run the RIMS off the same panel as the BK, I'd buy a separate RIMS system (from Brewhardware).

The panel, as it turns out, is overkill. It has a couple of push button switches to control pumps, but it's not that convenient for me, enough that I finally decided to add switches at the front of my bench more easily reached. It also allowed me to mount the pump in such an orientation that I can use it to move water from the BK to the MT, then recirculate wort through the RIMS, then move the wort back into the BK for boiling, then run the wort through my counterflow chiller at the end.

I'm not saying this is the best way, or only way, just it's how it works best for me, and may be something to consider as you figure out what works best in your situation.

First pic: you see the panel on the wall, and next to it is the black RIMS controller. Boil kettle on the right, Mash tun on the left, RIMS tube hanging off the front of the bench in front of the mash tun, counterflow chiller below the BK. Hose setup is to recirc through the counterflow chiller.

Second pic shows the hoses transferred over to recirculate wort through the RIMS into the MT.

Third pic shows the pump switches. I use only the Riptide pump during brewing operations; the second pump switch is for a pump I use to recirculate cleaning solution through my conical fermenter.

It's an easy reach for the pump switches this way. Having done it both using the push button switch on the control panel, and using these switches, no way on earth I'd go back to using the panel.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)