haeffnkr

Well-Known Member

Hello,

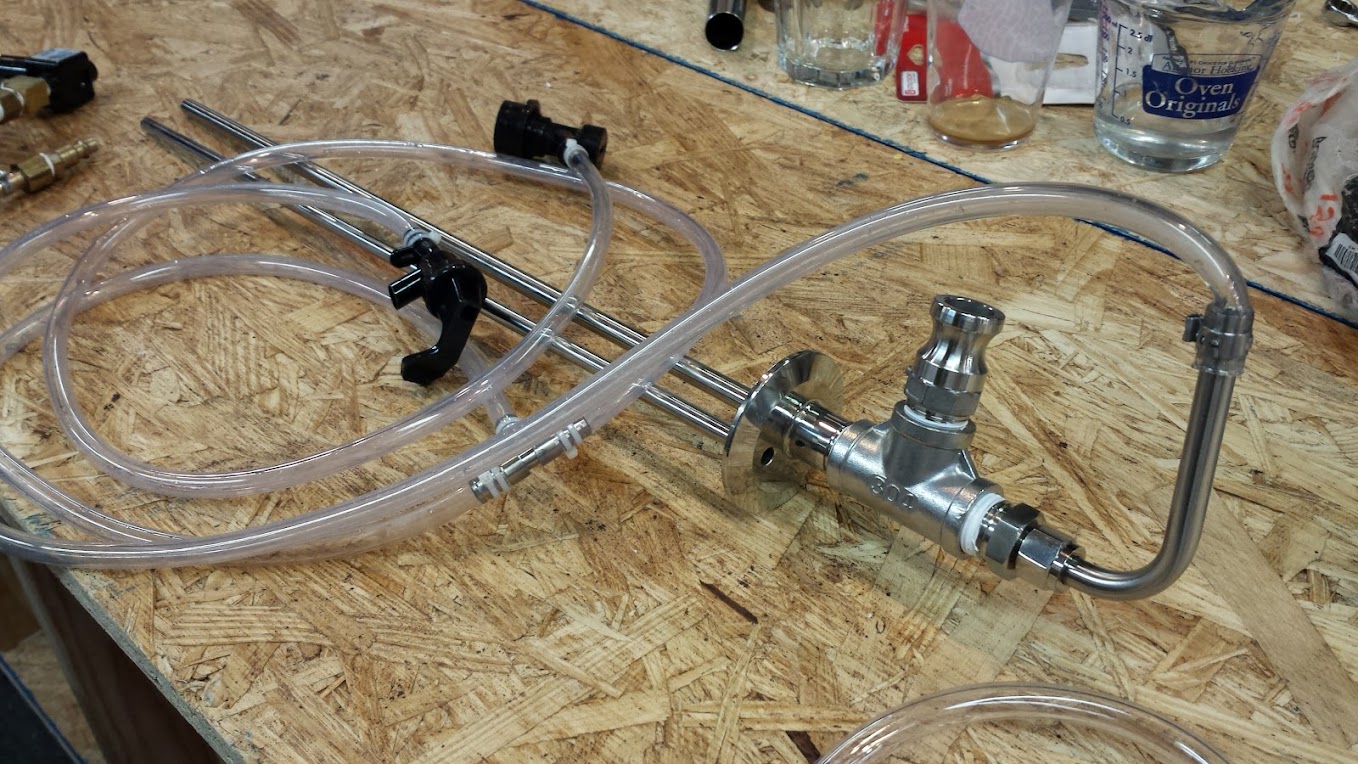

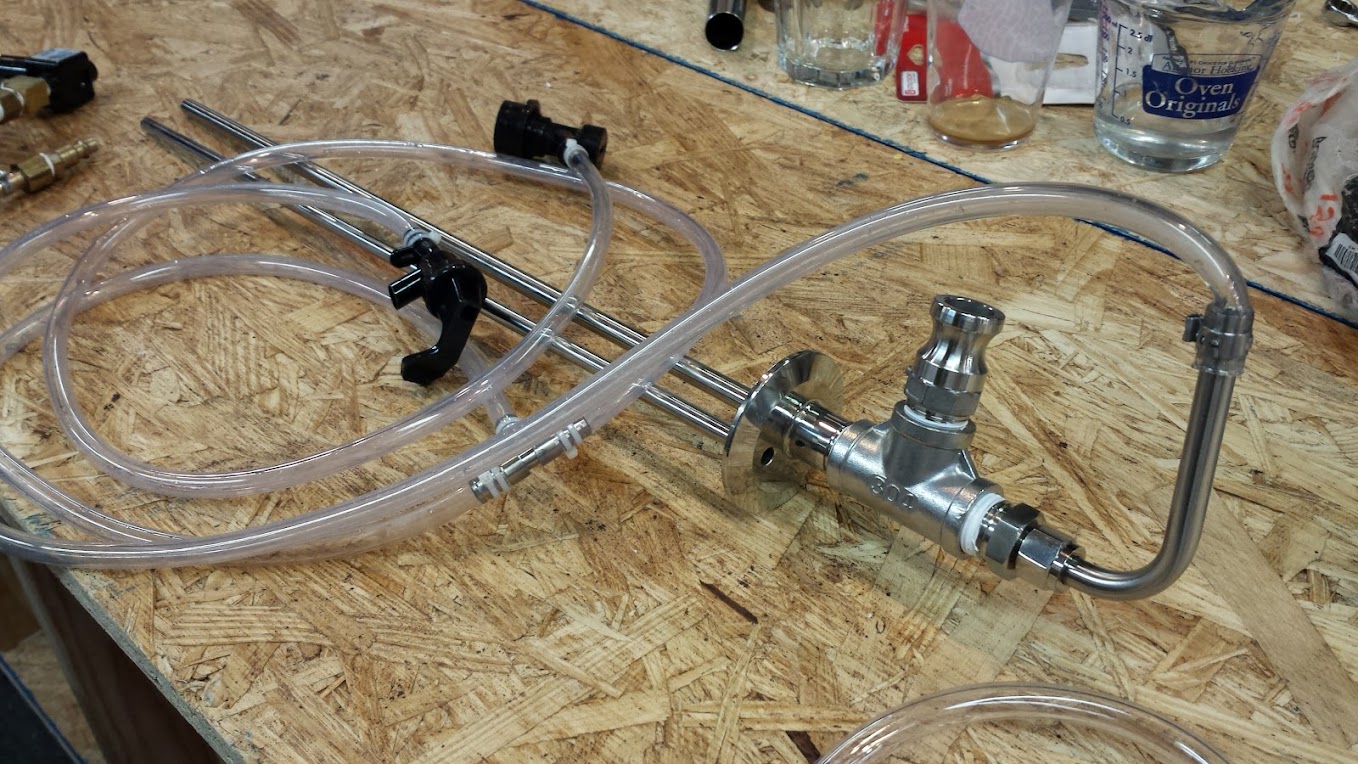

Thanks to you all I came up with my "coupler" design.

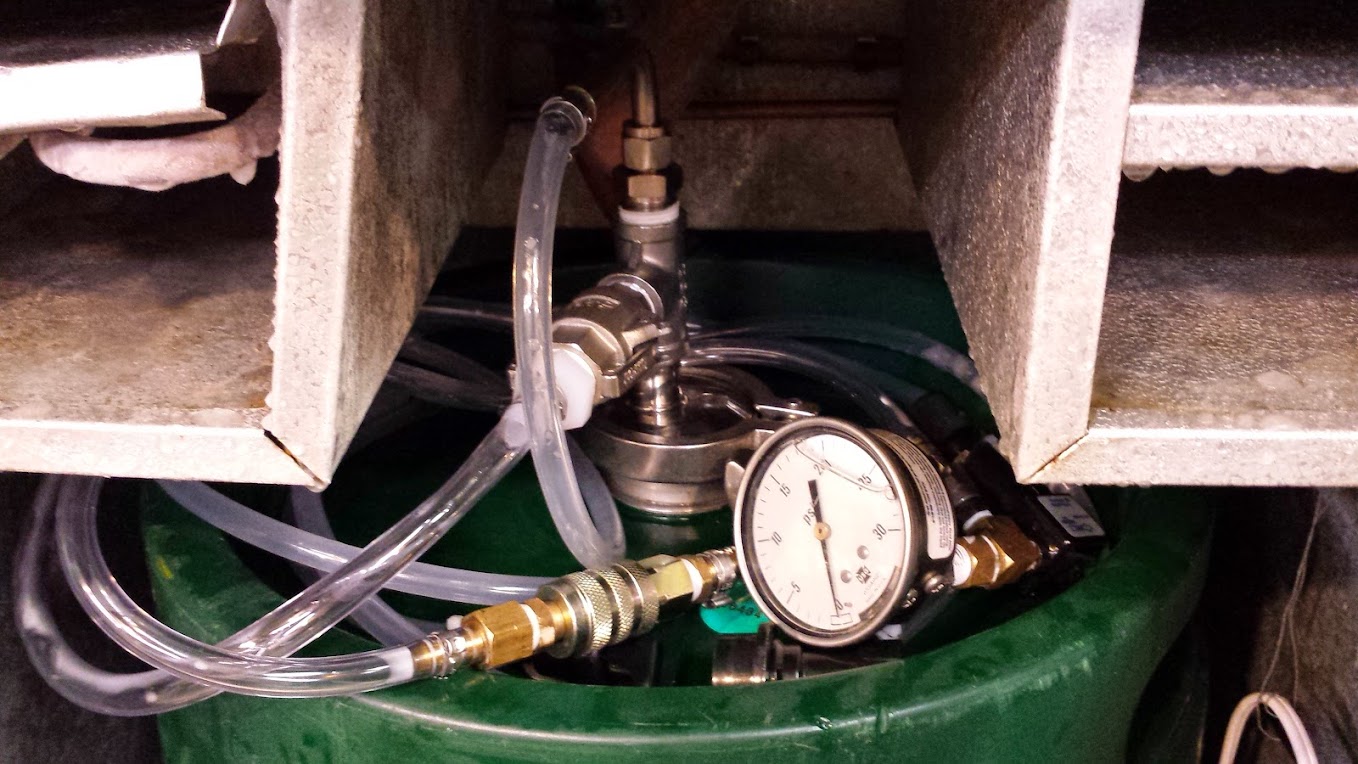

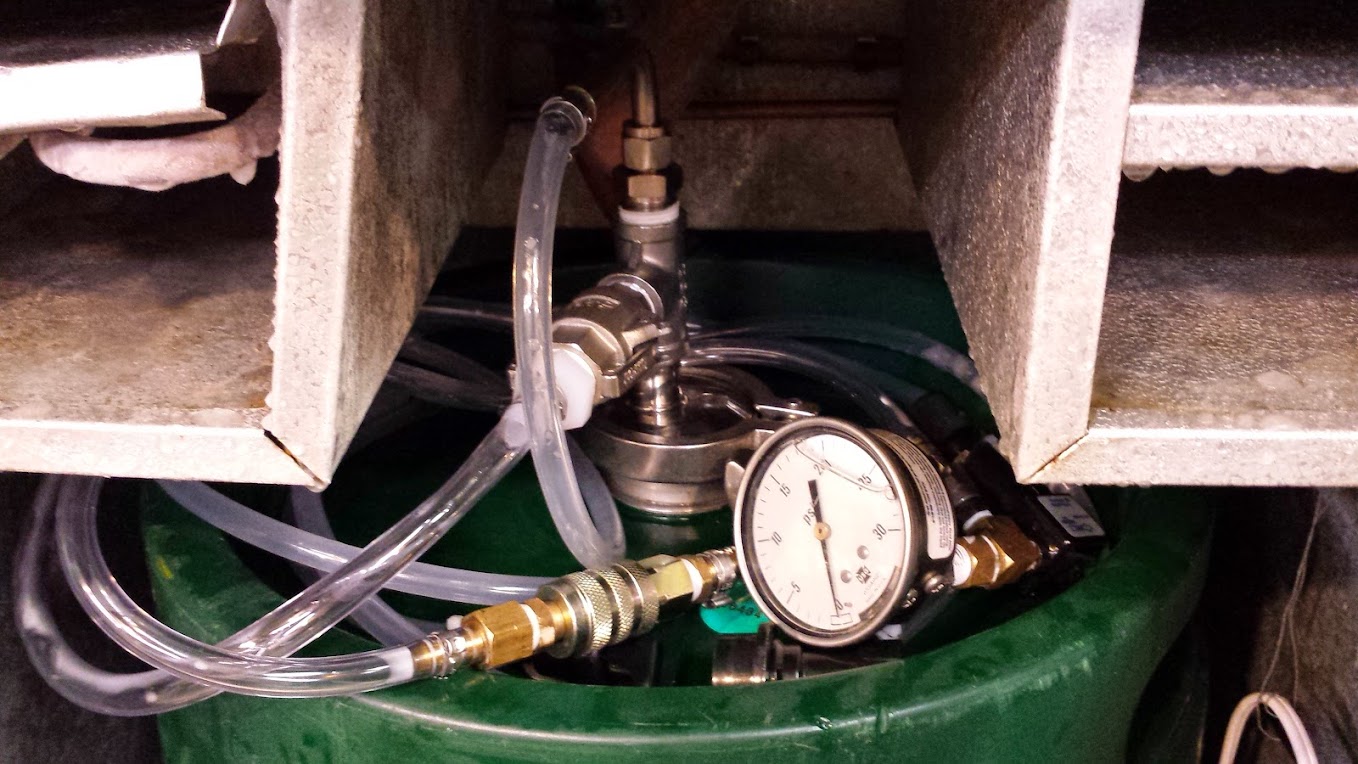

I will let you know how it works, this morning it was holding at 5 pounds.

Also - the first time I used the thermowell, I did not have to get tape to stick to the cold wet sides of the keg, It was worth the added expense to get the units from Bobby_M.

It was awesome.

Thanks again for all the tips and pics.

Comments welcome

Kevin

Thanks to you all I came up with my "coupler" design.

I will let you know how it works, this morning it was holding at 5 pounds.

Also - the first time I used the thermowell, I did not have to get tape to stick to the cold wet sides of the keg, It was worth the added expense to get the units from Bobby_M.

It was awesome.

Thanks again for all the tips and pics.

Comments welcome

Kevin

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)