You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sanch's official all tri clover rig build!!!

- Thread starter sanch

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

PaulHilgeman

Well-Known Member

- Joined

- Mar 14, 2008

- Messages

- 270

- Reaction score

- 7

Looks good, seems like that is how everyone is making their coils for these things! Did you solder, braze, or weld your connections?

sanch

Well-Known Member

Looks good, seems like that is how everyone is making their coils for these things! Did you solder, braze, or weld your connections?

I used sill foss 15 silver solder I have a friend that does HVAC he soldered it for me.

sanch

Well-Known Member

So correct me if I'm wrong here, but it looks like the flow on yours is up the middle pipe and then down through the coils to the exit pipe right?

the water flows down through the center then up through the coils, this helps avoid the the coils getting blocked by air pockets while heating.

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

sanch

Well-Known Member

No problems with cooling with that flowpath?

Also, is the solder holding up to the direct flame or how high off the burner and what burner are you using? Thanks

I dont know what you mean about the cooling I use this for heating only?

and It does that just fine.

The solder is holding up just fine I beleive it flows at 1200° and the pipe itself never gets more than a few ° hoter than the water inside.

sanch

Well-Known Member

I meant with the water cooling since it flows so far from the flame before going to the kettle.

The output temp is measured right before it enters the diffuser. If it is I would have no way of knowing. I just adjust the flame/water flow to hit my desired output temp.

Sorry I have not posted more about the flash boiler.

The coil sets inside a 6" stove pipe. The heat follows the coil all the way to the top. The bottom of the coil is about 3" from the burner.

here is a pic of the whole assembly.

This is the burner and stand. The stand has a piece of channel that I cut long ways to hang off the back of the brew rigg.

The coil inside the stove pipe. It is not properly mounted yet its just kind of hangin there on the inlet/outlet.

I hope that helps you and clarifies things better?

sanch

Well-Known Member

Well I have not been getting much done this week as I started a new job on wedsday and its kickin my butt. I did get a little of the pipe fabbed up.

The recirculation/strike and sparge input. I am just holding it together with masking tape untill next weekend when I will go to my buddys to do the welding.

Here is the mash drain.

from the bottom the 2" tri clover will accept the powered mash mixer

The BK input pipe

On the inside.

I still need to fab the BK#2 inlet and wire up the pumps and who knows what else? I am hoping to be brewing in two weeks.

The recirculation/strike and sparge input. I am just holding it together with masking tape untill next weekend when I will go to my buddys to do the welding.

Here is the mash drain.

from the bottom the 2" tri clover will accept the powered mash mixer

The BK input pipe

On the inside.

I still need to fab the BK#2 inlet and wire up the pumps and who knows what else? I am hoping to be brewing in two weeks.

EarthBound

Well-Known Member

here is a pic of the whole assembly.

Did you build it or buy it?

HLT is not needed when you have instant water heating, and steam for injection into the wort for step mashing. As to the construction of the boiler, it is 1/4" copper tube rolled over 2" plastic pipe, and soldered to 1/2" copper tube, or a customized Swagelok brass cap fitting. The tube around the coils is nothing more than 6" stove pipe, the burner is a 4" high pressure burner. Here is a link to the copper boiler I have built https://picasaweb.google.com/kevin.ladue/Boiler02#.

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

I've been heavily considering having a 4" triclamp welded to the bottom of my mash tun to use a triclamp to 1/2" NPT as a drain and then take off the triclamp to dump the grains. Bottom drains large enough for everything to dump out make cleanup SOOOO much easier.

Dude, that is a hellacious idea! How would you get around the false bottom? Maybe use a fancy manifold instead?

If you went this route, you could make a chute under the drain that you could direct into a bucket or trashcan. Sorta like a tippy dump, but without the tip!

sanch

Well-Known Member

I built the flash boiler as klaude described. it realy wasnt very difficult.

I dont have a HLT on my rigg. I do have two BKs. With the tippie dump and flash boiler I should be able to brew two seperate 10-12 gallon batches in about 5 hours. Or two of the same to fill a larger fermenter. wich I may do once I nail down a few recipes. the flash boiler really opens up a lot of posabillities.

I dont have a HLT on my rigg. I do have two BKs. With the tippie dump and flash boiler I should be able to brew two seperate 10-12 gallon batches in about 5 hours. Or two of the same to fill a larger fermenter. wich I may do once I nail down a few recipes. the flash boiler really opens up a lot of posabillities.

klyph

Well-Known Member

Dude, that is a hellacious idea! How would you get around the false bottom? Maybe use a fancy manifold instead?

If you went this route, you could make a chute under the drain that you could direct into a bucket or trashcan. Sorta like a tippy dump, but without the tip!

With the hinged false bottoms that have a handle, and since there's no diptube on my setup, you can pull the false bottom up through the grain. With a bucket underneath it'd be as simple as pushing it down through the hole.

Sorry for the threadjack, can't wait to see this thing in operation I have a triclamp fetish, and this system is hot.

sanch

Well-Known Member

With the hinged false bottoms that have a handle, and since there's no diptube on my setup, you can pull the false bottom up through the grain. With a bucket underneath it'd be as simple as pushing it down through the hole.

Sorry for the threadjack, can't wait to see this thing in operation I have a triclamp fetish, and this system is hot.

Don't worry about it. It is a great point. My pipe is only two inches but I am still going to test this out. I am thinking about attaching a shop vac and blasting it with a hose. I use my spent grain to feed my chickens, and the stupid ducks. So I want it as dry as I can get it. I usualy spread my grains on a window screen and dry them out on my patio roof. I dont want them to wet or dirty so I will clean the vacuum well and use water sparingly, maybe use a paint strainer to help remove the water. my false bottom is not hinged so I will have to come up with a plan to remove it. I will keep you all posted on the outcome.

Tri clovers are pretty sweet but let me warn you the glorious scrap yard find has become a glorious pain in the a$$. I am not trying to deter anyone from taking on this endeavor but unless you have a tig at home and a can use it with some proficiency this will only frustrate you. I could have been brewin months ago if I had gone the hose or copper pipe route. On the other hand I am very proud of my rig. My one regret is not going all out with full 3A sanitary process system. Although it is totally unnecessary I think that if you have or are going to spend the money on hard pipe/tri clovers you might as well.

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

Heh-heh....heh-heh...you said you're pipe is only 2 inches....heh-heh...heh-heh....

sanch

Well-Known Member

Heh-heh....heh-heh...you said you're pipe is only 2 inches....heh-heh...heh-heh....

Hey 2" is perfectly respectable is long as it is referring to girth and not length.

sanch

Well-Known Member

Got a bit done this weekend out at the shop.

The mash output piping/sight glass.

After we mounted it all up the sight glass was a bit crooked

We heated it with a torch to straiten it out

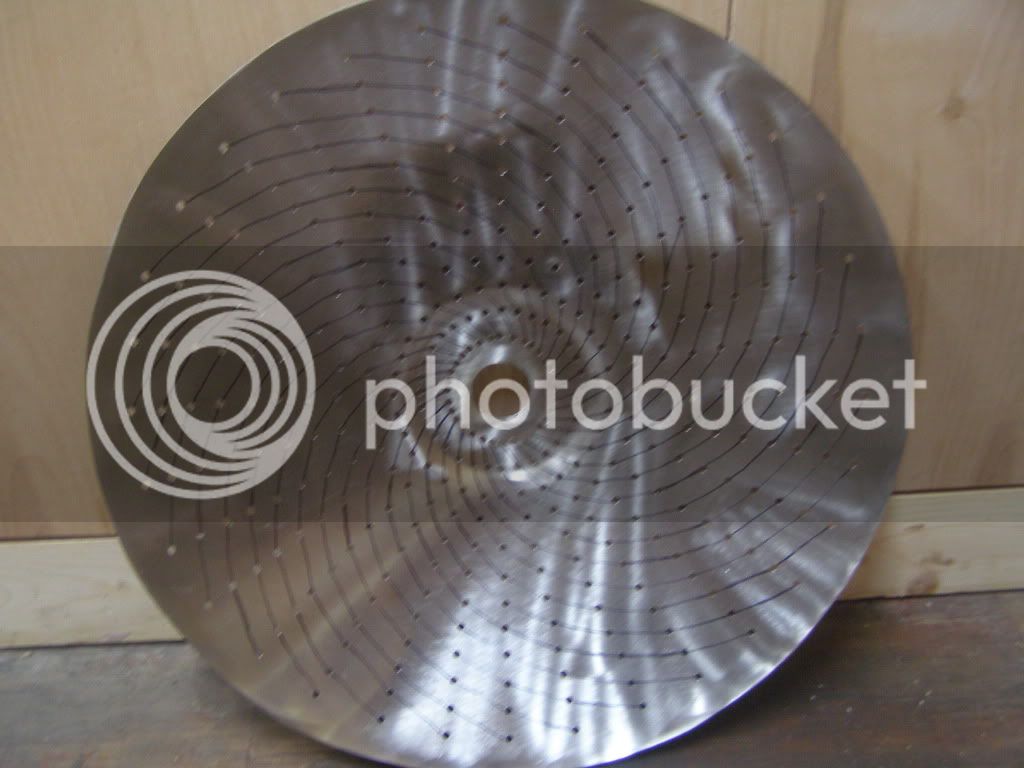

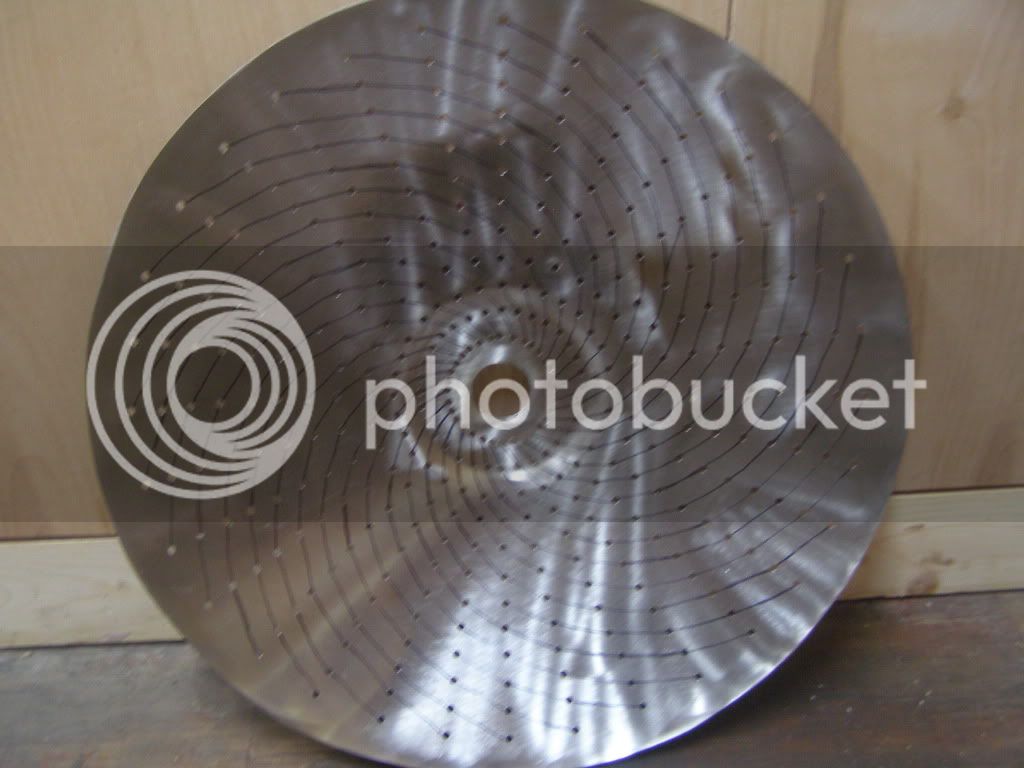

I also drilled a few hundred more holes in my false bottom

That's all for now will post more as soon as possible. I started working on the wiring for the pumps so I should be able to start testing the recirculation circuit tomorrow.

The mash output piping/sight glass.

After we mounted it all up the sight glass was a bit crooked

We heated it with a torch to straiten it out

I also drilled a few hundred more holes in my false bottom

That's all for now will post more as soon as possible. I started working on the wiring for the pumps so I should be able to start testing the recirculation circuit tomorrow.

sanch

Well-Known Member

I completed my ghetto wiring it is not finished product but it will work for some testing.

I know it does not have a GFCI built in yet but it is pluged in to a GFCI circuit.

This is the mash tun drain the block off plate will accept the mash mixer eventually.

The recirculation pipe circuit. I had to scrounge the gaskets from the every ware they were not being used.

I did get some testing done this after noon. The ambient input water temp was 87°

I fired up the flash boiler and turned on the water, I kind of messed with the flow rates a little and ended up with 122° water in the mash tun. about 5 gal in just under 5 minuets.

When I had 5 gal I shut down the boiler and waited for a while. Then I fired it back up and turned on the steam input 10 GPH. The temperature stabilized at 240° steam.

I turned on the pump (for the first time) and started the recirculation I soon noticed a sweet whirlpool in the MT it soon became so violent that the pump lost its prime. I just turned it of for a few seconds and was back in business. I chocked off the pump output valve to keep it from happening again.

It took about 8 minuets to reach 155°.

I also tested the sparge water output.

Over all I was very happy with the results. The march pumps flow faster and were quieter than I thought. The flash boiler did what it was supposed to do and the plumbing was nearly leak free. I hope to do a test brew over the long weekend. after I complete the BK2 plumbing and clean every thing.

I know it does not have a GFCI built in yet but it is pluged in to a GFCI circuit.

This is the mash tun drain the block off plate will accept the mash mixer eventually.

The recirculation pipe circuit. I had to scrounge the gaskets from the every ware they were not being used.

I did get some testing done this after noon. The ambient input water temp was 87°

I fired up the flash boiler and turned on the water, I kind of messed with the flow rates a little and ended up with 122° water in the mash tun. about 5 gal in just under 5 minuets.

When I had 5 gal I shut down the boiler and waited for a while. Then I fired it back up and turned on the steam input 10 GPH. The temperature stabilized at 240° steam.

I turned on the pump (for the first time) and started the recirculation I soon noticed a sweet whirlpool in the MT it soon became so violent that the pump lost its prime. I just turned it of for a few seconds and was back in business. I chocked off the pump output valve to keep it from happening again.

It took about 8 minuets to reach 155°.

I also tested the sparge water output.

Over all I was very happy with the results. The march pumps flow faster and were quieter than I thought. The flash boiler did what it was supposed to do and the plumbing was nearly leak free. I hope to do a test brew over the long weekend. after I complete the BK2 plumbing and clean every thing.

trevor_b

Well-Known Member

Awesome build!

android

Well-Known Member

very impressive man, keep the pics coming!

orangehero

Well-Known Member

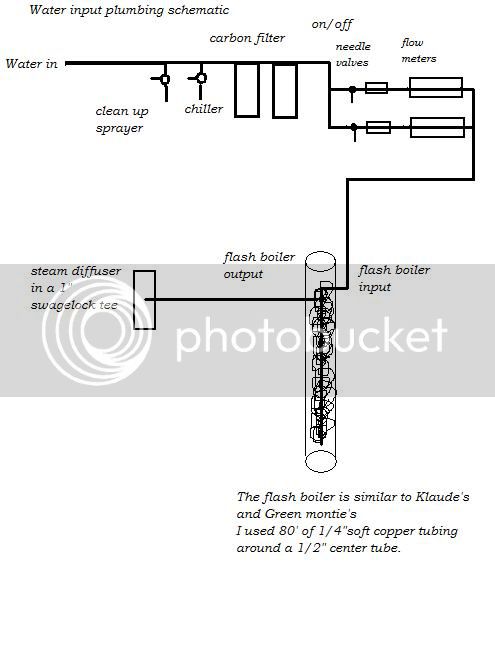

Is this diagram correct? I don't understand why you have the two flow meters and valves in parallel.

sanch

Well-Known Member

Is this diagram correct? I don't understand why you have the two flow meters and valves in parallel.

one of the valve/flow meter sets is tuned for steam output and the outher is tuned for sparge water output so all you have to do is light the burner and open the valve and the water comes out at the temp desired. or very close to it. also it hapened to work out that if you open both valves the output temp is very close to strike water temp.

Great Build. I plan on building a flash boiler based on these designs, can't wait to step mash with steam and do away with the HLT.

Sanch: Do you have any pictures of your diffuser? I know I have seen pictures of one somewhere but can't seem to find them now.

Thanks

Sanch: Do you have any pictures of your diffuser? I know I have seen pictures of one somewhere but can't seem to find them now.

Thanks

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 1

- Views

- 1K

- Replies

- 12

- Views

- 3K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)