Hey all! Been brewing for a few years and never run into this before.

tl;dr no fermentation followed by mold, salvaged what I could by siphoning from the bottom, planned to pitch new yeast, but the salvaged portion appears to have begun fermentation on its own. Should I bother pitching new yeast?

--------------------------------------------

So, I cooked up a wee heavy and pitched yeast like normal. The smack pack didn't swell after breaking the nutrient packet, but I gave it a shot anyways.

There was no fermentation by the end of day 2 in the carboy, so I ordered some rescue yeast. Some time midday day 3 there was clear mold growth:

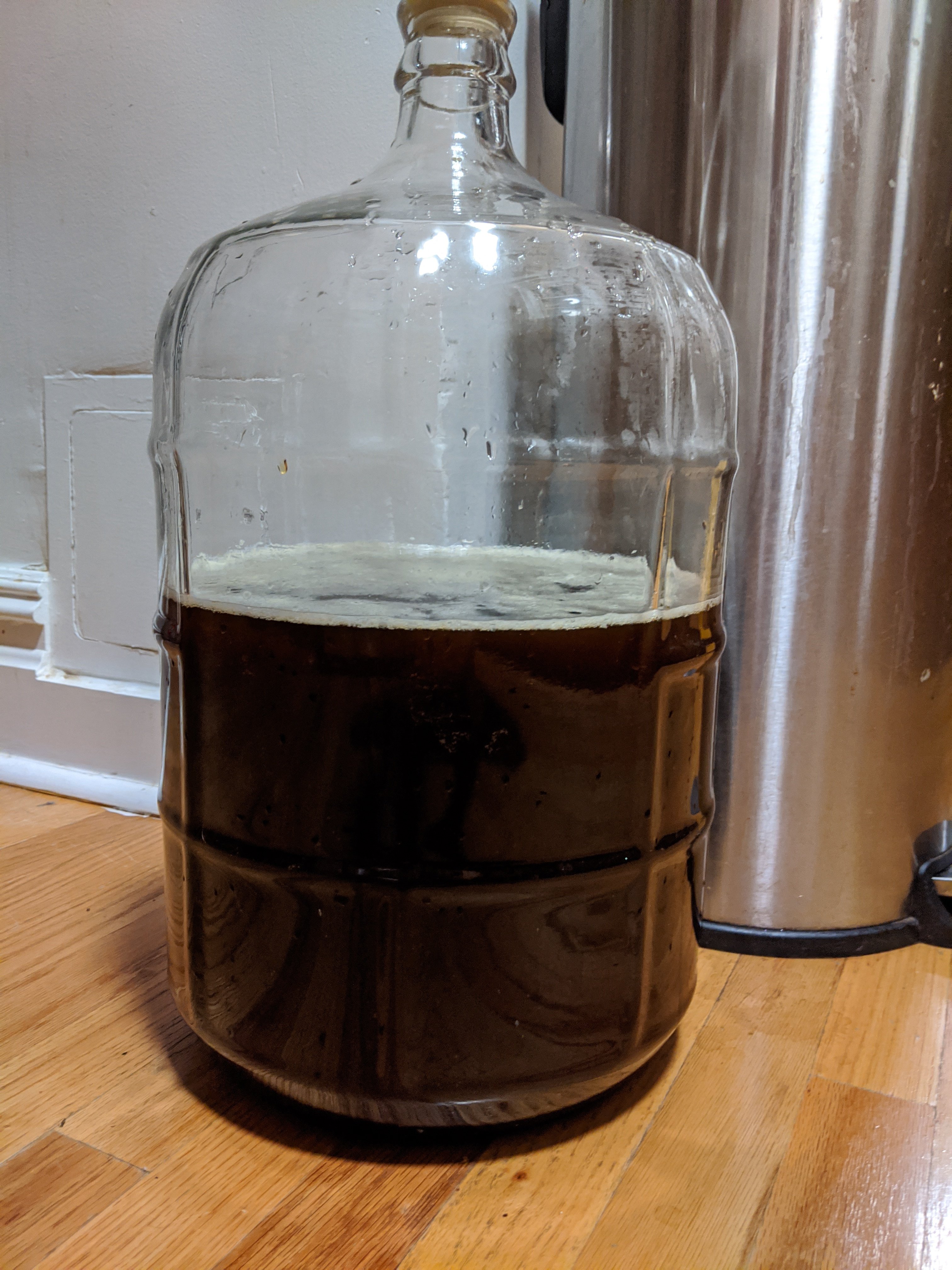

I picked a clear spot on the surface and stuck the racking cane in, siphoned from deep in the carboy, and left the top ~1.5in to avoid the mold if possible:

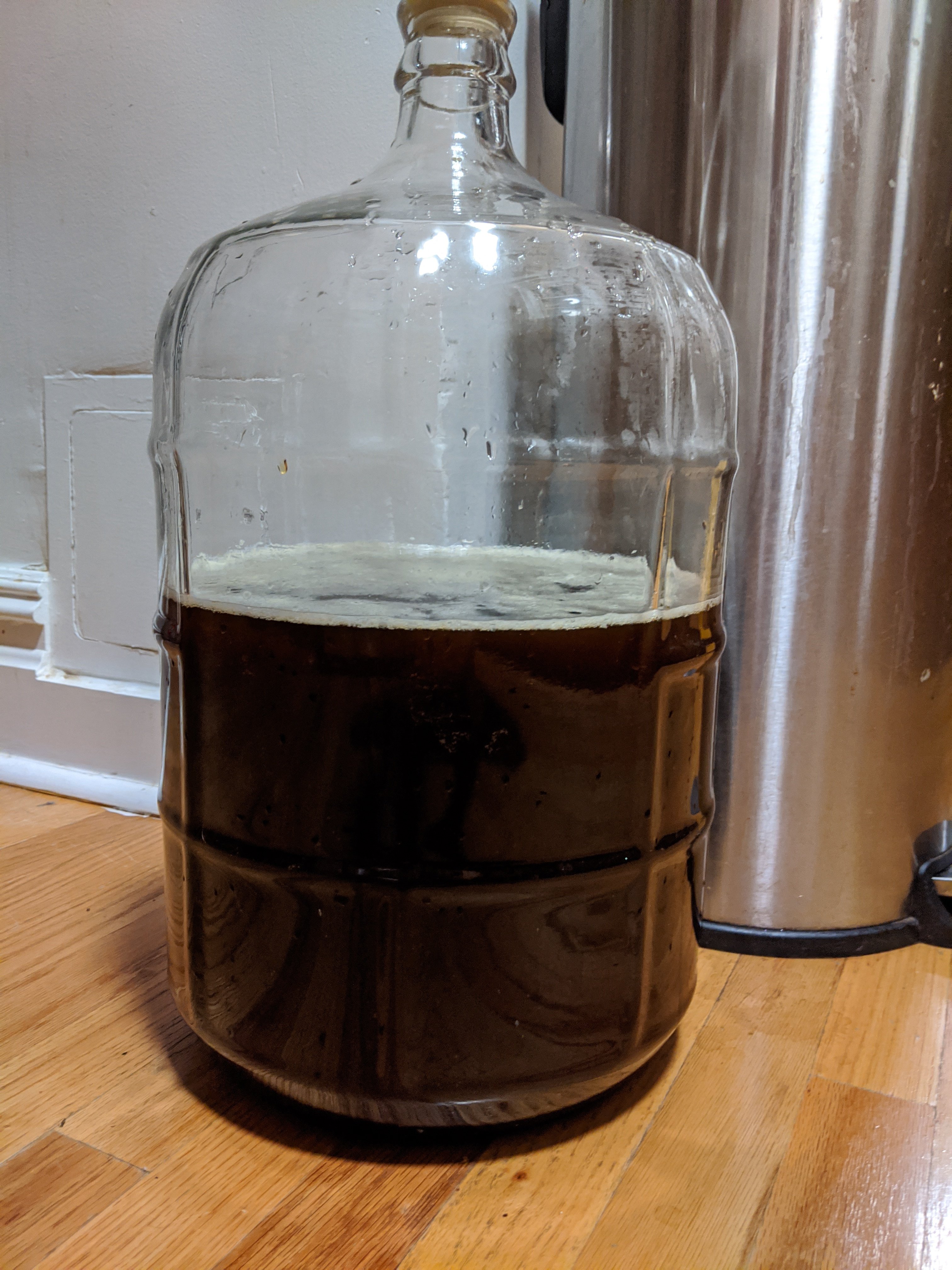

Well, since there was no fermentation for three days followed by mold, I assumed I didn't have any viable yeast and would need to pitch again, but morning of day 4 the salvaged portion appears to be fermenting without any additional yeast:

At this point I'm unsure whether or not to pitch. What do you wizened experts think is the most likely scenario - some of the old yeast finally woke up, and I can save the second round of yeast for a new beer? I've got some other fermenter in there? If the latter, would pitching new yeast to compete with whomever's taken up residence be advisable?

tl;dr no fermentation followed by mold, salvaged what I could by siphoning from the bottom, planned to pitch new yeast, but the salvaged portion appears to have begun fermentation on its own. Should I bother pitching new yeast?

--------------------------------------------

So, I cooked up a wee heavy and pitched yeast like normal. The smack pack didn't swell after breaking the nutrient packet, but I gave it a shot anyways.

There was no fermentation by the end of day 2 in the carboy, so I ordered some rescue yeast. Some time midday day 3 there was clear mold growth:

I picked a clear spot on the surface and stuck the racking cane in, siphoned from deep in the carboy, and left the top ~1.5in to avoid the mold if possible:

Well, since there was no fermentation for three days followed by mold, I assumed I didn't have any viable yeast and would need to pitch again, but morning of day 4 the salvaged portion appears to be fermenting without any additional yeast:

At this point I'm unsure whether or not to pitch. What do you wizened experts think is the most likely scenario - some of the old yeast finally woke up, and I can save the second round of yeast for a new beer? I've got some other fermenter in there? If the latter, would pitching new yeast to compete with whomever's taken up residence be advisable?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)